Preparation method of biological compound fertilizer

A compound fertilizer, biological technology, applied in microorganism-based methods, biochemical equipment and methods, carbon preparation/purification, etc., can solve the problems of increased metals and toxic elements, difficult transformation and degradation of substances, and reduced microbial activity, etc. Achieve the effect of reducing bulk density, increasing saturated hydraulic conductivity, and enhancing adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

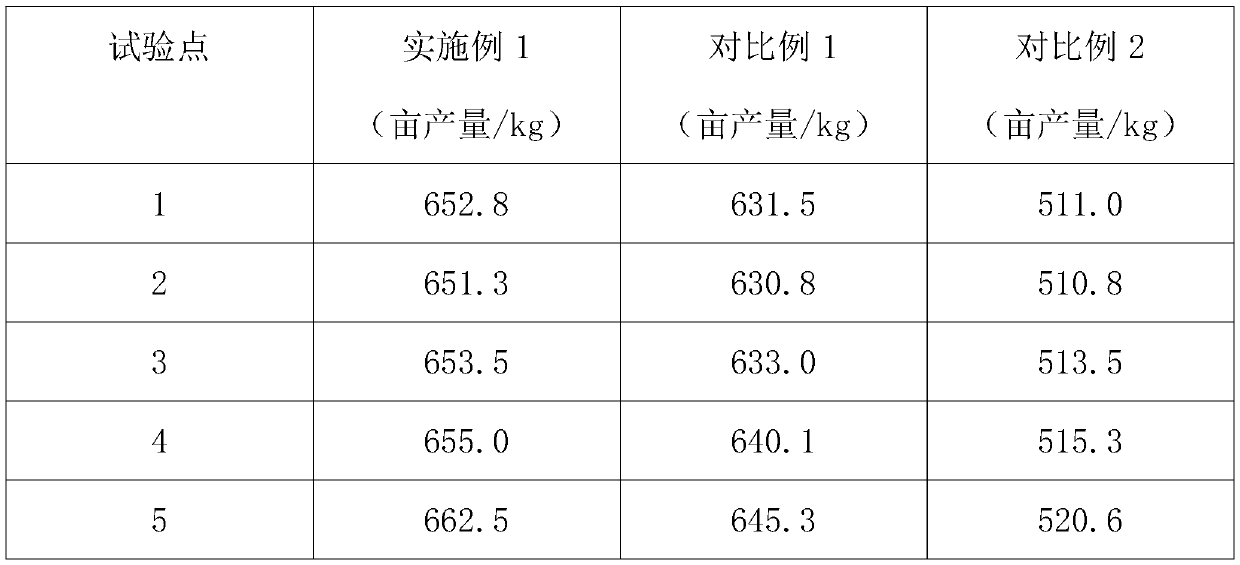

Examples

Embodiment 1

[0032] A preparation method of biological compound fertilizer, comprising the steps of:

[0033] Step S1, weighing the following raw materials by weight: 10 parts of composite biological bacteria preparation, 6 parts of modified biochar, 5 parts of 5% amino acid solution, 20 parts of urea, 3 parts of ammonium sulfate, 0.5 part of calcium phosphate, and 5 parts of trace element nutrient solution , 25 parts of glycerol;

[0034] Step S2. Grind the modified biochar and calcium phosphate, pass through a 100-mesh sieve, add deionized water and mix evenly, add dilute hydrochloric acid with a mass fraction of 10% to adjust the pH until the pH is 4.5, heat in a water bath at 80°C and heat at 180r / m Magnetically stirred at a speed of 1 min, stirred for 3 hours, filtered, washed three times with deionized water, transferred to an 85°C drying oven for 45 minutes, added 5% amino acid solution, and stirred evenly to obtain the first mixture;

[0035] Step S3, mix urea, ammonium sulfate an...

Embodiment 2

[0046] A preparation method of biological compound fertilizer, comprising the steps of:

[0047] Step S1, weighing the following raw materials by weight: 12 parts of composite biological bacteria preparation, 7 parts of modified biochar, 6 parts of 5% amino acid solution, 22 parts of urea, 3 parts of ammonium sulfate, 0.8 part of calcium phosphate, 6 parts of trace element nutrient solution , 28 parts of glycerol;

[0048] Step S2. Grind the modified biochar and calcium phosphate, pass through a 100-mesh sieve, add deionized water and mix evenly, add dilute hydrochloric acid with a mass fraction of 10% to adjust the pH until the pH is 4.5, heat in a water bath at 80°C and heat at 180r / m Magnetically stirred at a speed of 1 min, stirred for 3 hours, filtered, washed three times with deionized water, transferred to an 85°C drying oven for 45 minutes, added 5% amino acid solution, and stirred evenly to obtain the first mixture;

[0049] Step S3, mix urea, ammonium sulfate and tr...

Embodiment 3

[0052] A preparation method of biological compound fertilizer, comprising the steps of:

[0053] Step S1, weighing the following raw materials by weight: 14 parts of composite biological bacteria preparation, 8 parts of modified biochar, 8 parts of 5% amino acid solution, 28 parts of urea, 4 parts of ammonium sulfate, 1.2 parts of calcium phosphate, and 8 parts of trace element nutrient solution , 30 parts of glycerol;

[0054] Step S2. Grind the modified biochar and calcium phosphate, pass through a 100-mesh sieve, add deionized water and mix evenly, add dilute hydrochloric acid with a mass fraction of 10% to adjust the pH until the pH is 4.5, heat in a water bath at 80°C and heat at 180r / m Magnetically stirred at a speed of 1 min, stirred for 3 hours, filtered, washed three times with deionized water, transferred to an 85°C drying oven for 45 minutes, added 5% amino acid solution, and stirred evenly to obtain the first mixture;

[0055] Step S3, mix urea, ammonium sulfate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com