Preparation method and application of glycosylated neohesperidin dihydrochalcone

A technology of hesperidin dihydrochalcone and glycosylation, which is applied in the field of bioengineering, can solve the problems of low solubility, long after-sweet time, slow sweet taste, etc., and achieves increased solubility, improved before-sweet and after-sweet , the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of glycosylated neomethylhesperidin dihydrochalcone, the specific steps comprising:

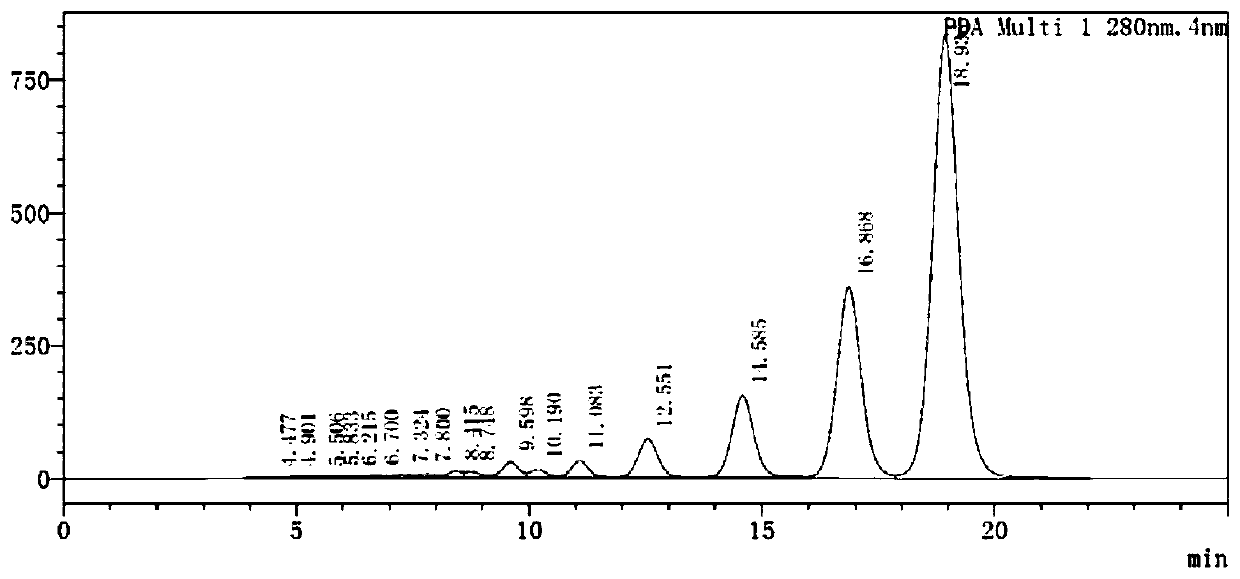

[0031] Using neohesperidin dihydrochalcone as a raw material, the reaction buffer is a disodium hydrogen phosphate-sodium citrate buffer with a mass fraction of 0.9%, the pH of the buffer is 4.9, and the ratio of the raw material to the reaction buffer is 1 : 25, the reaction temperature is 55°C, and the reaction time is controlled for 6h; then in the reaction system, rhamnosidase:glucosyltransferase=15:80, the mass fraction of the total enzyme is 10% of the input neohesperidin dihydrochalcone %, add 10g / L of glucose to the system. In this reaction system, the yield of glycosylated neomethylhesperidin dihydrochalcone is 98.2%. HPLC detection results such as figure 1 , it can be seen from the figure that the reaction system can effectively glycosylate neomethylhesperidin dihydrochalcone, because the number of sugar groups linked by polyglycosylated neomethylhesper...

Embodiment 2

[0033] A preparation method of glycosylated neomethylhesperidin dihydrochalcone, the specific steps comprising:

[0034] Using neohesperidin dihydrochalcone as raw material, the reaction buffer is disodium hydrogen phosphate-sodium citrate buffer with a mass fraction of 0.1%, the pH of the reaction buffer is 2, and the ratio of the raw material to the reaction buffer is 1 : 10, the reaction temperature is 50°C, and the reaction time is controlled for 4h. Then in the reaction system, rhamnosidase:glucosyltransferase=10:90, the mass fraction of the total enzyme is 15% of the input neohesperidin dihydrochalcone %, add 5g / L glucose in the system. In this reaction system, the yield of glycosylated neomethylhesperidin dihydrochalcone is 80.1%.

Embodiment 3

[0036] A preparation method of glycosylated neomethylhesperidin dihydrochalcone, the specific steps comprising:

[0037] Using neohesperidin dihydrochalcone as a raw material, the reaction buffer is a disodium hydrogen phosphate-sodium citrate buffer with a mass fraction of 1%, the pH of the reaction buffer is 8, and the ratio of the raw material to the reaction buffer is 1 : 50, reaction temperature 60 ℃, reaction time control 6h, then in the reaction system rhamnosidase: glucosyltransferase = 90: 10, the mass fraction of total enzyme is 20% of the input neohesperidin dihydrochalcone %, add 5g / L rhamnose to the system. In this reaction system, the yield of glycosylated neomethylhesperidin dihydrochalcone is 96.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solubility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com