Ethylene-propylene-diene monomer reinforcing agent as well as preparation method and application thereof

A technology of EPDM rubber and reinforcing agent, which is applied in the direction of textiles and papermaking, non-fiber pulp addition, coating, etc., which can solve the problem of insignificant improvement in tensile strength and folding resistance, and adverse effects on the appearance of paper cultural relics, etc. problem, to achieve the effect of simple and convenient preparation method, improving the ability to resist the erosion of external unfavorable conditions, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of EPDM reinforcing agent, it is made by melt grafting reaction by 10g EPDM rubber, 0.3g maleic anhydride as graft monomer and 0.3g styrene as co-monomer.

[0035] The above-mentioned EPDM reinforcing agent is specifically prepared through the following steps:

[0036] 1) According to the above raw material ratio, dissolve maleic anhydride in styrene, then add EPDM rubber and stir to make it evenly mixed to obtain reaction solution A, wherein, in order to fully carry out the reaction, the above-mentioned EPDM The rubber is granular, and the particle size is in the range of 0.1mm-0.3mm. It is mainly made of blocky EPDM rubber cut into small pieces, and then crushed by a high-speed mixer;

[0037] 2) Add the reaction solution A to the micro-twin-screw extruder, and keep the screw speed (reaction speed) at 42r / min, and the reaction temperature at 200°C, so that the materials in the reaction solution A are melted and grafted to obtain the product B ;

[0038] 3) We...

Embodiment 2

[0043]The difference between this example and Example 1 is that in this example, the comonomer for preparing the EPDM rubber reinforcement is methyl methacrylate. Among them, the test results of the gel rate during the preparation of the EPDM reinforcement are shown in Table 1.

Embodiment 3

[0045] The difference between this example and Example 1 is that in this example, the comonomer for preparing the EPDM reinforcement is acrylic acid. Among them, the test results of the gel rate during the preparation of the EPDM reinforcement are shown in Table 1.

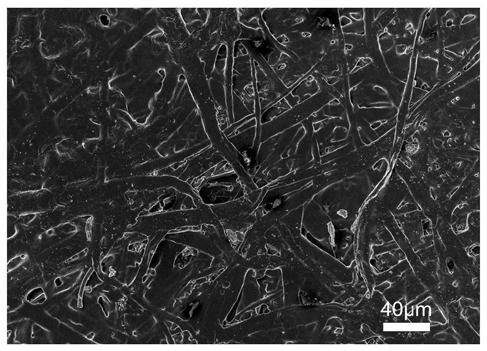

[0046] In order to clearly characterize the influence of the EPDM reinforcing agent of the present invention on the paper pattern appearance, the EPDM reinforcing agent with a mass percentage concentration of 0.4% was selected to be prepared from the EPDM reinforcing agent of Example 1. Glue-coated paper sample, after natural drying at room temperature, conduct SEM test, the test results are as follows figure 1 shown.

[0047] Depend on figure 1 It can be seen that, with the EPDM reinforcing glue prepared by the EPDM reinforcing agent of Example 1 of the present invention, after the paper is processed, the original part of the mesh structure of the paper pattern is maintained, which macroscopically affects the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| gel rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com