Acid-base resistant high-temperature-resistant waterborne polyurethane coating and preparation method thereof

A water-based polyurethane, high-temperature-resistant technology, applied in the field of coatings, can solve problems such as limited use range and poor stability, and achieve the effects of good chemical resistance, improved heat exchange efficiency, and good heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

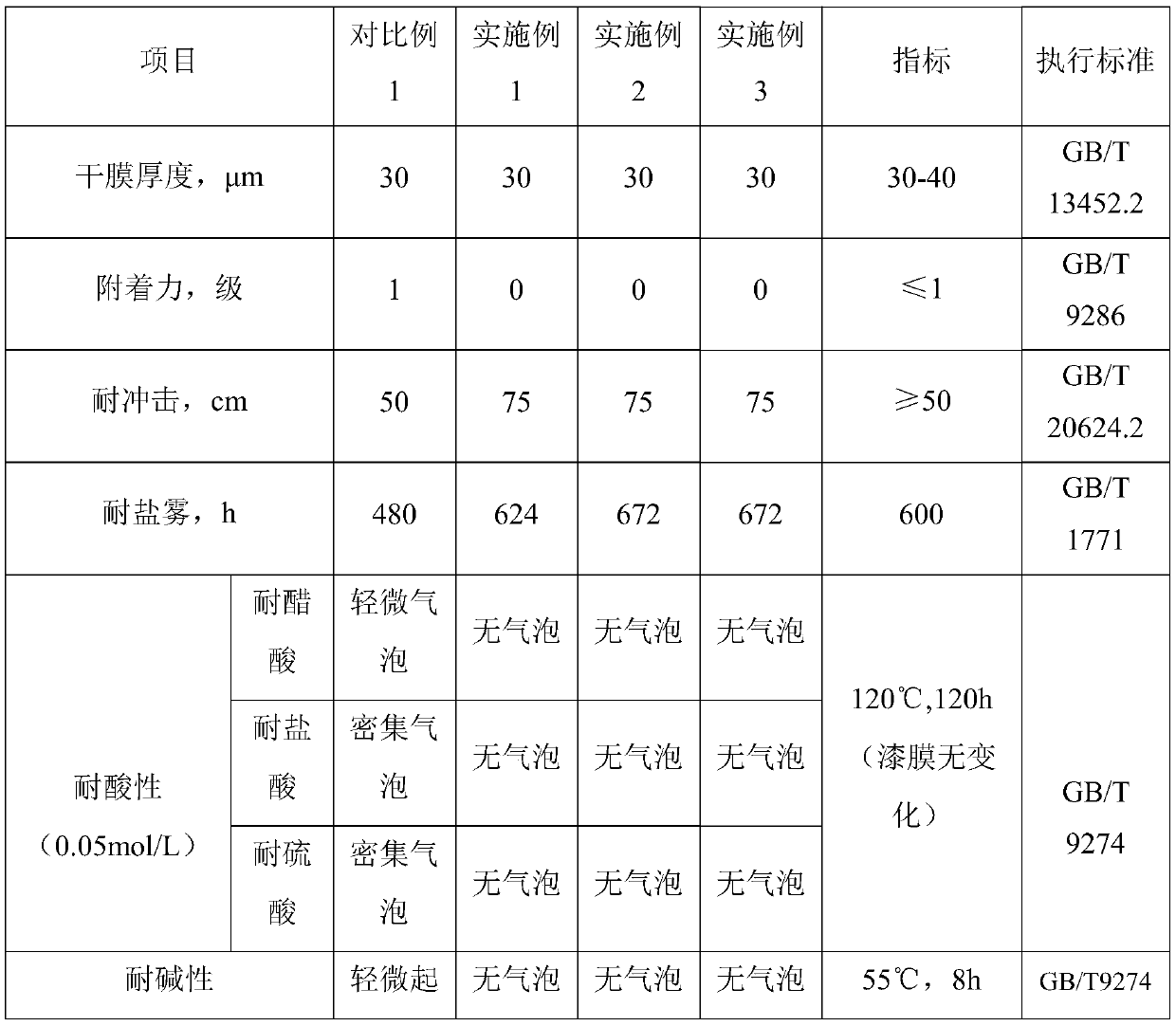

Examples

Embodiment 1

[0035] An acid, alkali and high temperature resistant waterborne polyurethane coating, comprising the following components by weight: A component and B component, the mass ratio of A component and B component is 9:1;

[0036] Among them, component A includes the following components by weight: 28 parts of deionized water, 4 parts of graphene sol, 10 parts of film-forming aid dipropylene glycol butyl ether, 1 part of dispersant Disperbyk-190, and defoamer byk-024 4 parts, 1 part of leveling agent byk-348, 50 parts of water-based polyurethane emulsion Dispercoll U2710 and 2 parts of thickener DOW ACRYSOL RM-12W;

[0037] Component B includes the following components in parts by weight: 40 parts of propylene glycol methyl ether acetate, 55 parts of water-based polyisocyanate curing agent Aquolin 268, 4 parts of anti-flash rust agent SER-AD FA 179, and 1 part of defoamer TEGO 901W.

[0038] The above-mentioned graphene sol is prepared by the following method: add 3kg dispersant CO...

Embodiment 2

[0054] An acid, alkali and high temperature resistant waterborne polyurethane coating, comprising the following components by weight: A component and B component, the mass ratio of A component and B component is 9:1;

[0055]Among them, component A includes the following components by weight: 25 parts of deionized water, 7 parts of graphene sol, 10 parts of film-forming aid dipropylene glycol butyl ether, 1 part of dispersant Disperbyk-190, and defoamer byk-024 4 parts, 1 part of leveling agent byk-348, 50 parts of water-based polyurethane emulsion Dispercoll U2710 and 2 parts of thickener DOW ACRYSOL RM-12W;

[0056] Component B includes the following components in parts by weight: 40 parts of propylene glycol methyl ether acetate, 55 parts of water-based polyisocyanate curing agent Aquolin 268, 4 parts of anti-flash rust agent SER-AD FA 179, and 1 part of defoamer TEGO 901W.

[0057] The above-mentioned graphene sol is prepared by the following method: add 3kg dispersant COA...

Embodiment 3

[0073] An acid, alkali and high temperature resistant waterborne polyurethane coating, comprising the following components by weight: A component and B component, the mass ratio of A component and B component is 9:1;

[0074] Among them, component A includes the following components by weight: 22 parts of deionized water, 10 parts of graphene sol, 10 parts of film-forming aid dipropylene glycol butyl ether, 1 part of dispersant Disperbyk-190, and defoamer byk-024 4 parts, 1 part of leveling agent byk-348, 50 parts of water-based polyurethane emulsion Dispercoll U2710 and 2 parts of thickener DOW ACRYSOL RM-12W;

[0075] Component B includes the following components in parts by weight: 40 parts of propylene glycol methyl ether acetate, 55 parts of water-based polyisocyanate curing agent Aquolin 268, 4 parts of anti-flash rust agent SER-AD FA 179, and 1 part of defoamer TEGO 901W.

[0076] The above-mentioned graphene sol is prepared by the following method: add 3kg dispersant C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com