Method used for catalytic oxidation removing of dibenzothiophenes in oil products with zeolite molecular sieve loaded composite catalyst

A zeolite molecular sieve and composite catalyst technology, which is applied in the field of dibenzothiophene, can solve the problems of limiting the wide application of solid-phase supported catalysts, limiting the application of solid-phase supported catalysts, and the difficulty of successful loading of transition metals, and achieves fast, efficient and effective. Effects of conversion, good economic benefits and application prospects, high catalytic oxidation rate and catalytic oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

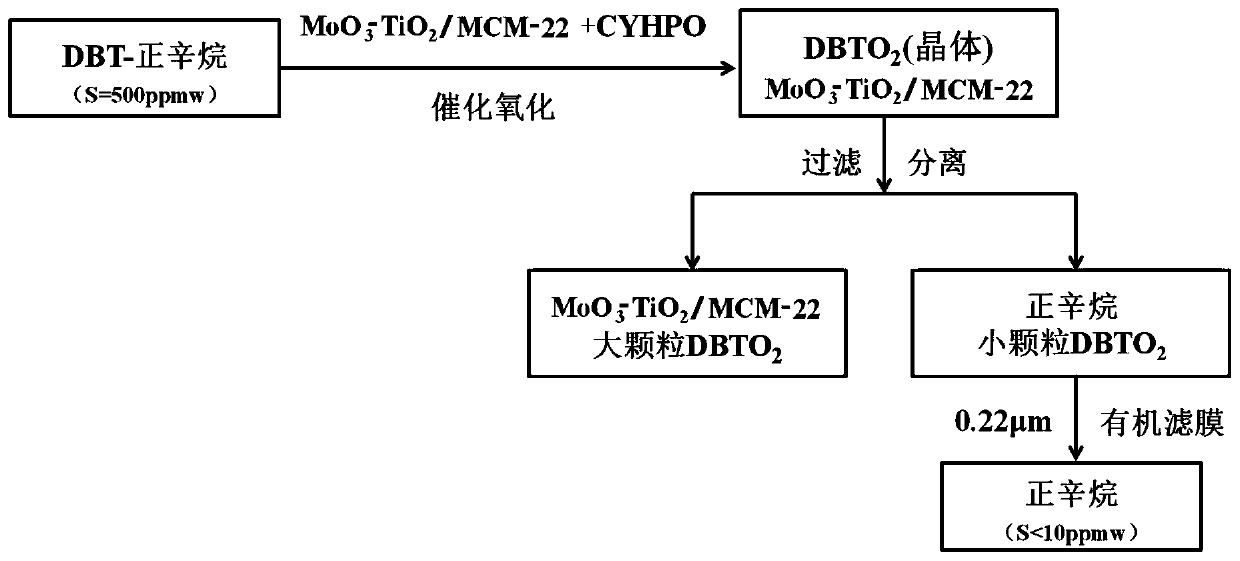

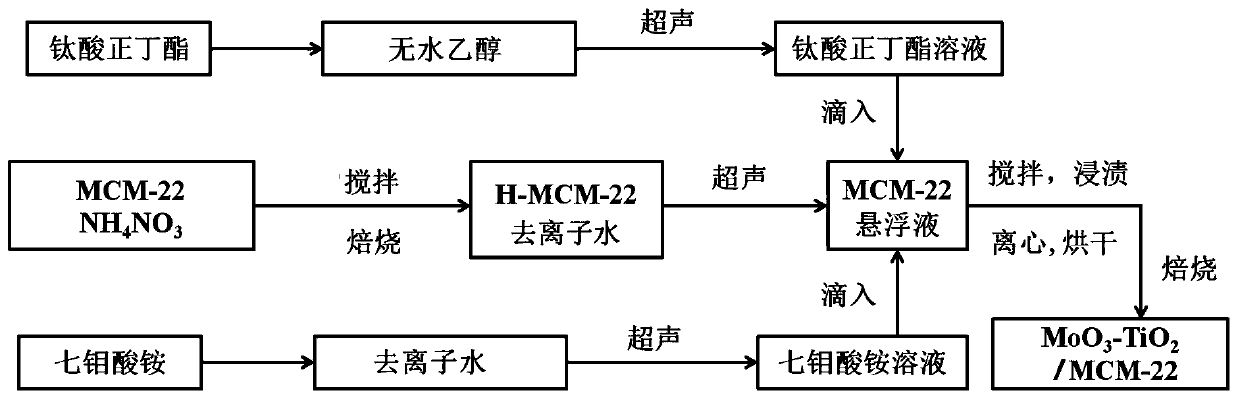

[0046] A method for removing dibenzothiophene from oil by catalytic oxidation of zeolite molecular sieve supported composite catalyst, the process flow diagram is as follows figure 1 shown, including the following steps:

[0047] Take zeolite molecular sieve supported composite catalyst (A1, A2, A3, A4, A5), titanium dioxide / zeolite molecular sieve composite catalyst (B1), molybdenum trioxide / zeolite molecular sieve composite catalyst (B2), each 0.10g, add to 20mL, Add 280 μL of cyclohexanone peroxide (CYHPO / Oxidizing agent, O / S=2) solution, the temperature is 100 ℃ in the oil bath pot under magnetic stirring, carry out catalytic oxidation reaction 30min, wherein during the catalytic oxidation reaction process dibenzothiophene (DBT) is converted into dibenzothiophene sulfone (DBTO 2 ) crystals; after the reaction is completed, cool to room temperature, filter the product solution after the catalytic oxidation reaction, and filter and separate the catalyst in the product sol...

Embodiment 2

[0072] A method for removing dibenzothiophene in oil by catalytic oxidation of a zeolite molecular sieve supported composite catalyst, comprising the following steps:

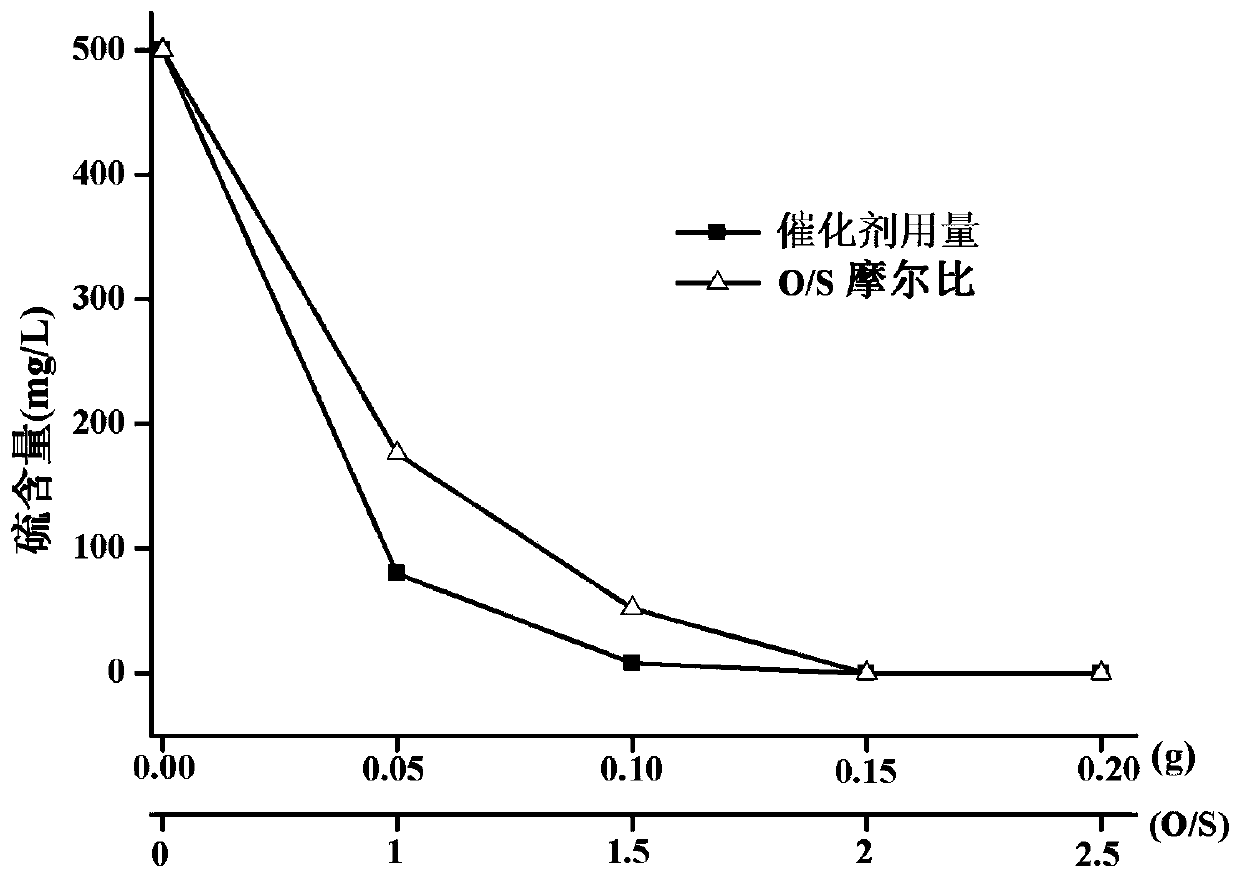

[0073] Get 4 groups of zeolite molecular sieve supported composite catalysts (A1) prepared in Example 1, the quality is successively 0.05g, 0.10g, 0.15g, 0.20g, add to 20mL respectively, the dibenzothiophene with sulfur concentration of 500ppmw In (DBT)-n-octane solution (that is, simulated petroleum containing dibenzothiophene), the mixed solutions numbered C1, C2, C3, and C4 in turn; to the mixed solutions numbered C1, C2, C3, and C4 Add 140 μ L, 210 μ L, 280 μ L, 350 μ L of cyclohexanone peroxide solution in turn (the O / S in these solutions of cyclohexanone peroxide is 1, 1.5, 2, 2.5 in turn, and the mass fraction of cyclohexanone peroxide solution is 50 %), in an oil bath at a temperature of 100°C under magnetic stirring, the catalytic oxidation reaction was carried out for 15 minutes, wherein during the ca...

Embodiment 3

[0077] A method for removing dibenzothiophene in oil by catalytic oxidation of a zeolite molecular sieve supported composite catalyst, comprising the following steps:

[0078] Get 5 groups of zeolite molecular sieve supported composite catalysts (A1) prepared in Example 1, every group of 0.10g, add respectively to 20mL, dibenzothiophene (DBT)-n-octane solution (i.e. 280 μL of cyclohexanone peroxide (oxidizing agent, O / S=2) solution with a mass fraction of 50% was added to the simulated petroleum containing dibenzothiophene), respectively, at 40°C, 60°C, and 80°C , 100°C, 120°C in an oil bath under magnetic stirring for 30 minutes, wherein dibenzothiophene (DBT) is converted into dibenzothiophene sulfone (DBTO) during the catalytic oxidation reaction 2 ) crystals; after the reaction is completed, cool to room temperature, filter the product solution after the catalytic oxidation reaction, and filter and separate the catalyst in the product solution from the simulated petroleum,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com