Tunnel flexible ring type supporting system suitable for passing through movable fault zone

A support system and flexible ring technology, applied in the direction of tunnels, tunnel linings, shaft equipment, etc., can solve problems such as increasing construction economic costs, tunnel collapse, secondary lining peeling, etc., to achieve low overall operating costs, reduce tensile and compressive stress, The effect that the construction method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

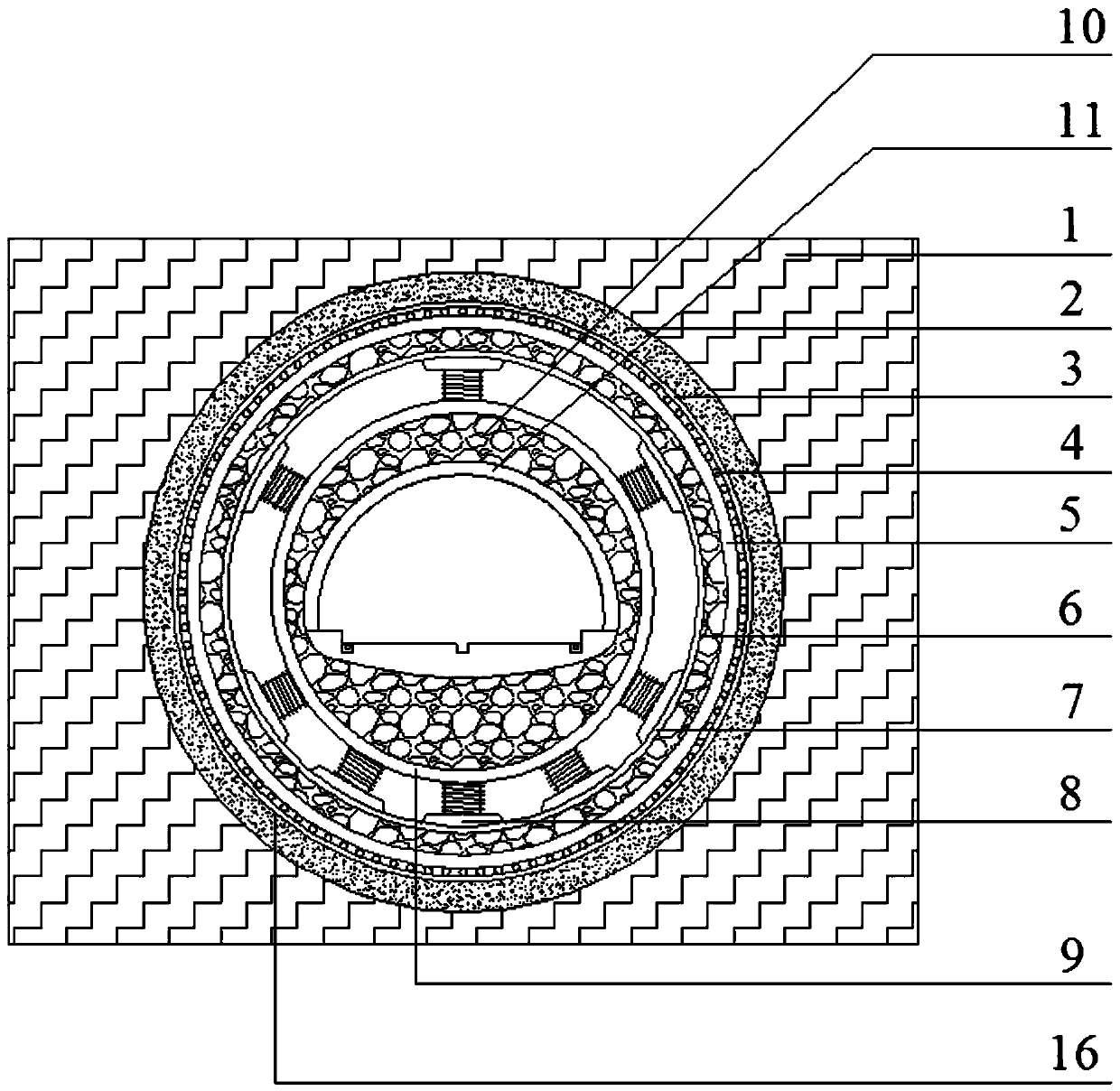

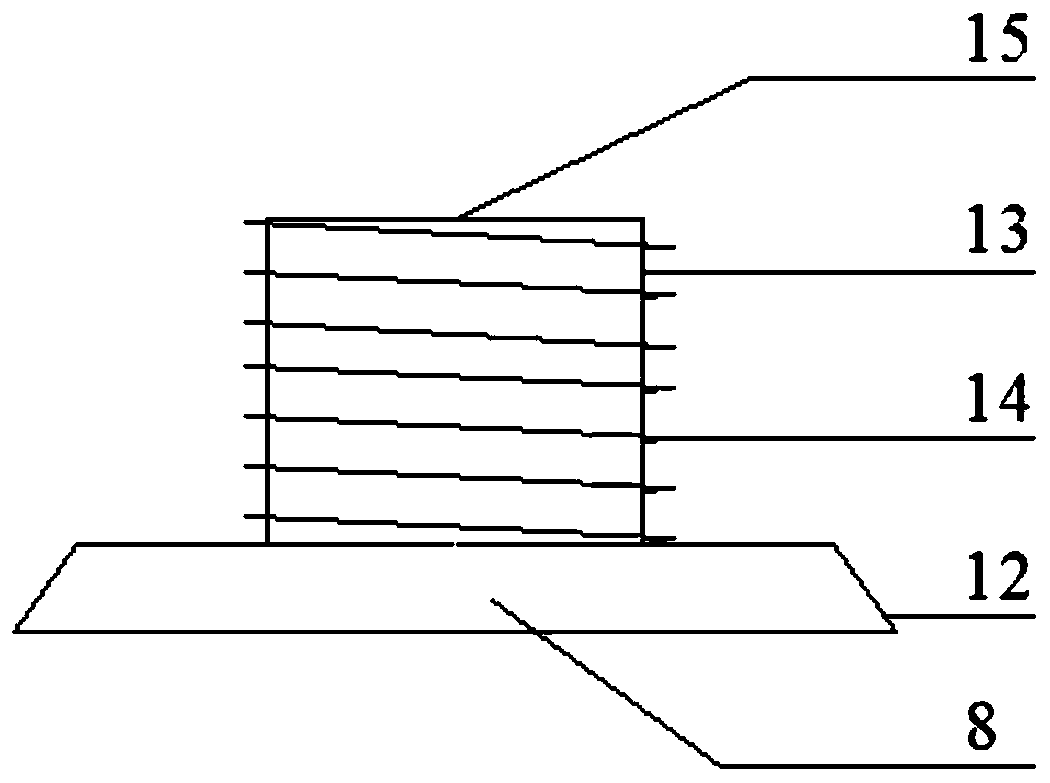

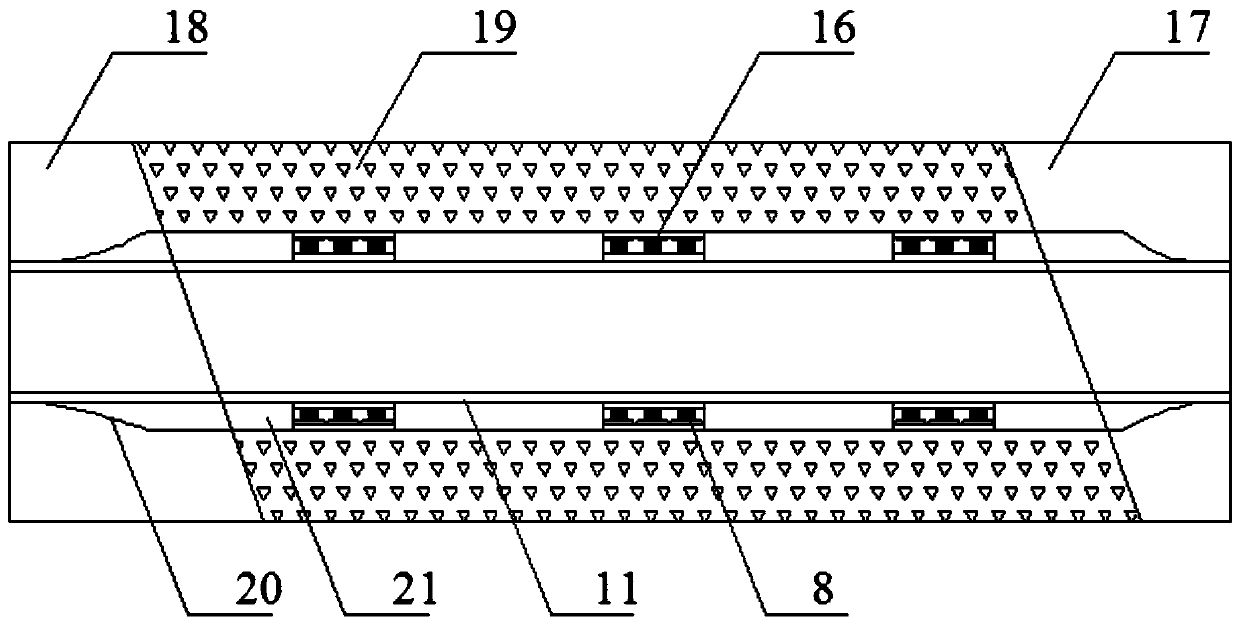

[0057] Such as Figure 1-Figure 3 As shown, a flexible ring-type support system for tunnels suitable for crossing active fault zones is sequentially set up as surrounding rock grouting reinforcement layer 1, primary support layer 2, anchor mesh layer 3, steel bar row 4, and the first ring-shaped support system from outside to inside. Steel arch 5, rubber cushioning layer 6, second annular steel arch 7, support cylinder 8, third annular steel arch 9, rubber particle filling layer 10 and prefabricated steel pipe tunnel 11;

[0058] Surrounding rock grouting reinforcement layer 1 injects polymer grouting material into the surrounding rock mass after tunnel expansion to reinforce the surrounding rock in the fault fracture zone; the primary branch layer 2 is excavated and formed at the tunnel section to complete the grouting reinforcement After the operation, the ribbed steel bar is laid and the concrete is sprayed along the circular contour of the surrounding rock of the tunnel, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com