Exhaust gas treatment system and test method of a gasoline engine bench

A gasoline engine and exhaust gas treatment technology, used in engine testing, exhaust treatment, engine components, etc., can solve the problems of low harmful gas treatment capacity, inability to deal with dischargeable values, and easy occurrence of urea crystallization, so as to reduce urea Crystallization risk, improved catalytic conversion efficiency, avoided or unsupported effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

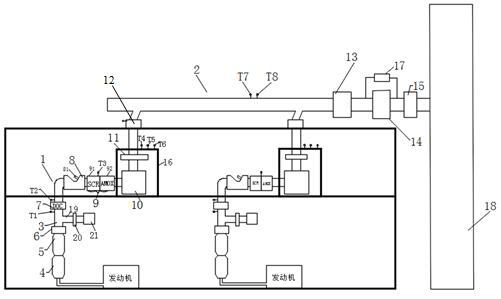

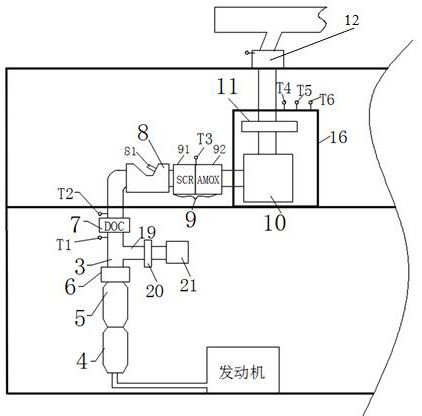

[0024] Please refer to figure 1 , figure 2 , an exhaust gas treatment system for a gasoline engine bench, including an exhaust gas test module 1 and a manifold 2; the exhaust gas test module 1 includes an exhaust pipeline 3, and the exhaust pipeline 3 and the manifold 2 adopt 316 Made of stainless steel, the surface is provided with an insulation layer, and the insulation layer is covered with aluminum skin.

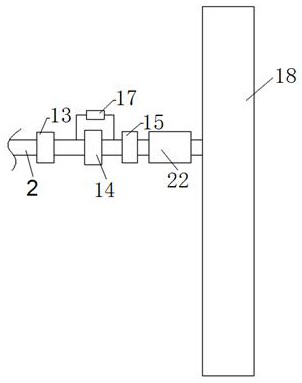

[0025] The exhaust pipeline 3 is arranged in sequence with a pre-catalyzed three-way catalytic device 4, a main three-way catalytic device 5, a muffler 6, a DOC device 7, a decomposition pipe 8, an SCR device 9, a high-temperature fan 10, a high-temperature cut-off valve 11 and Water washing tower 12; the outside of high temperature fan 10 is provided with a noise reduction house 16 for reducing noise, and the end of exhaust pipeline 3 is connected with main pipe 2; said main pipe 2 is provided with metal blanket filter 13 and main fan 14 in turn , muffler 15; the end...

Embodiment 2

[0031] In order to facilitate maintenance, this patent adopts a modular design. The difference between this embodiment and Embodiment 1 is that the number of exhaust gas test modules 1 set on the main pipe 2 is not less than two. In this way, one module If the other one is broken, it can continue to work, and only one needs to be replaced, which saves costs, and the work can continue to improve work efficiency.

Embodiment 3

[0033] In order to reduce noise, the outside of the high-temperature fan 10 is provided with a noise reduction house 16, and the noise reduction house 16 is provided with a No. 1 pressure sensor T4, a No. 3 temperature sensor T5, and a No. 2 NOx sensor T6; There are No. 4 temperature sensor T7 and No. 3 NOx sensor T8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com