Low-protein amino-acid-balanced piglet concentrated feed

A technology of concentrated feed and amino acids, applied in the direction of animal feed, animal feed, additional food elements, etc., can solve the problems of tight supply and high price of plant protein raw materials, and achieve environmental protection and animal health, improve utilization, and balance diets. Effects of Amino Acid Levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

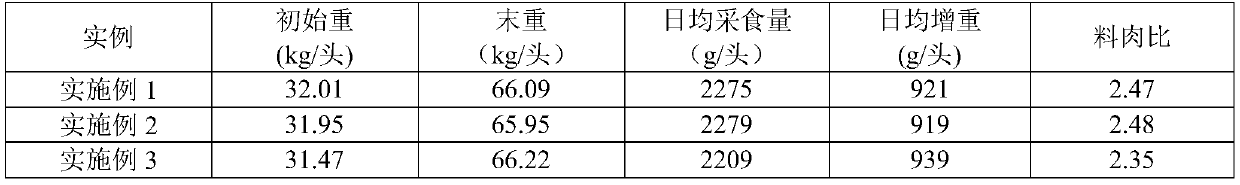

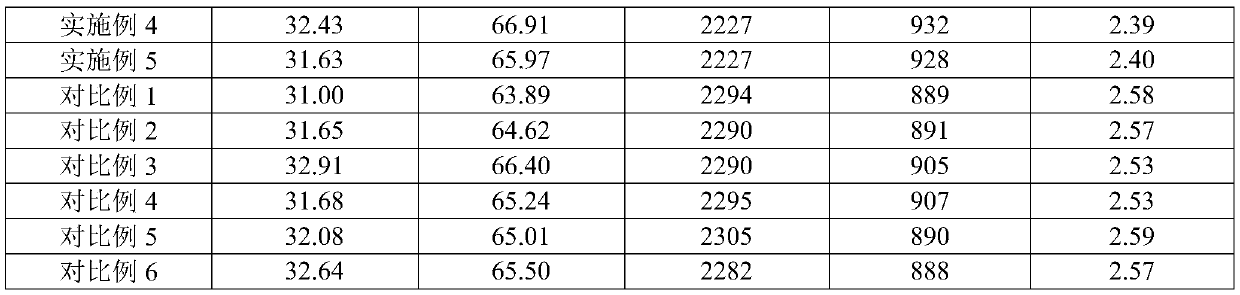

Examples

Embodiment 1

[0027] A low-protein balanced amino acid concentrated feed for piglets, including raw materials by weight percentage: 7.5% functional additive semi-finished products, 61.9% soybean meal, 8.8% stone powder, 10.5% calcium hydrogen phosphate, 4.3% sodium chloride, 4.5% lysine acid, 1.1% methionine, 1.2% threonine and 0.2% tryptophan.

[0028] Among them, the functional additive semi-finished product consists of 24% multivitamin, 26% compound trace element, 10.8% phytase, 21.7% compound enzyme preparation, 1.0% amelamycin premix, 4.6% kitasamycin Composed of a premix and 11.9% grain bran carrier, the preparation method of the functional additive semi-finished product includes weighing each raw material of the above formula and putting them into a mixer and mixing them uniformly for 1 minute to obtain the functional additive semi-finished product.

[0029]The preparation steps of the low-protein balance amino acid concentrated feed for piglets include: respectively weighing the soy...

Embodiment 2

[0033] A low-protein balanced amino acid concentrated feed for piglets, including raw materials by weight percentage: 8.5% functional additive semi-finished products, 56.3% soybean meal, 9.7% stone powder, 12.0% calcium hydrogen phosphate, 4.7% sodium chloride, 5.2% lysine acid, 1.5% methionine, 1.6% threonine and 0.5% tryptophan.

[0034] Among them, the functional additive semi-finished product is composed of 26% multivitamin, 24% compound trace element, 9.8% phytase, 19.6% compound enzyme preparation, 0.8% amelamycin premix, 4.6% kitasamycin Composed of a premix and 15.2% grain bran carrier, the preparation method of the functional additive semi-finished product includes weighing each raw material of the above formula and putting them into a mixer for uniform mixing for 3 minutes to obtain the functional additive semi-finished product.

[0035] The preparation steps of the low-protein balance amino acid concentrated feed for piglets include: respectively weighing the soybea...

Embodiment 3

[0039] A low-protein balanced amino acid concentrated feed for piglets, including raw materials by weight percentage: 8% semi-finished functional additives, 59% soybean meal, 9.4% stone powder, 11.2% calcium hydrogen phosphate, 4.5% sodium chloride, 4.8% lysine acid, 1.3% methionine, 1.4% threonine and 0.4% tryptophan.

[0040] Among them, the functional additive semi-finished product is calculated by weight percentage, consisting of 25% compound vitamins, 25% compound trace elements, 10.38% phytase, 20.88% compound enzyme preparation, 1% amelamycin premix, 5.24% kitasamycin Composed of a premix and 12.5% grain bran carrier, the preparation method of the functional additive semi-finished product includes weighing each raw material of the above formula respectively and putting them into a mixer for uniform mixing for 2 minutes to obtain the functional additive semi-finished product.

[0041] The preparation steps of the low-protein balance amino acid concentrated feed for pig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com