Resin-based nano composite material, preparation method and method for deeply removing copper- citric acid from water

A technology of nanocomposite materials and composite materials, applied in the field of wastewater treatment, to achieve the effects of large specific surface area, high adsorption capacity, and strong adsorption selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The resin-based nanocomposite material of this embodiment is synthesized according to the following steps:

[0056] 1) Dissolve 10 g of zirconium oxychloride in an acidic aqueous solution with pH=1.5; make zirconium exist in ion form.

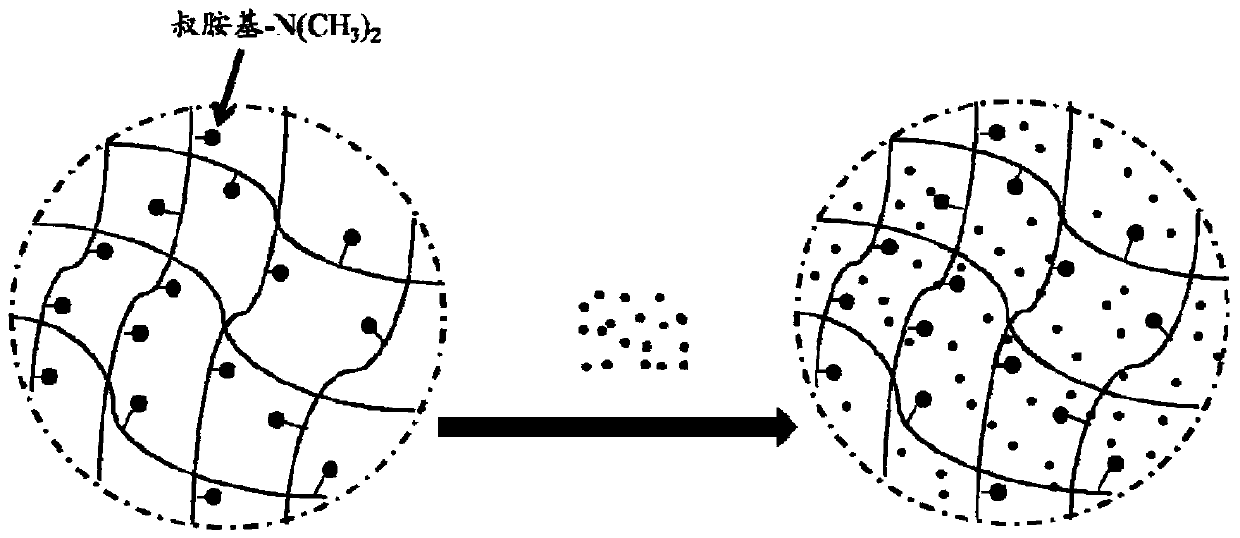

[0057] 2) Take tertiary aminated styrene-divinylbenzene copolymer spheres, add them to the solution system prepared in step 1), the mass ratio of the copolymer spheres to zirconium oxychloride is 1:1, and then heat it in a water bath to 70 ℃, open; keep stirring for 12 hours under the condition of 300rpm;

[0058] Regulating the mass ratio of copolymerized spheres and zirconium oxychloride is to control the loading capacity of nano-hydration zirconia, and the purpose of exposure and heating is to promote the hydrolysis and concentration of zirconium salt;

[0059] 3) After step 2) is completed, the copolymerized spheres are taken out, air-dried naturally, and then transferred to a NaOH solution with a mass concentration of 10%. The mass...

Embodiment 2

[0069] The water body depth of present embodiment 2 removes the method for Cu-citric acid complex, comprises the following steps:

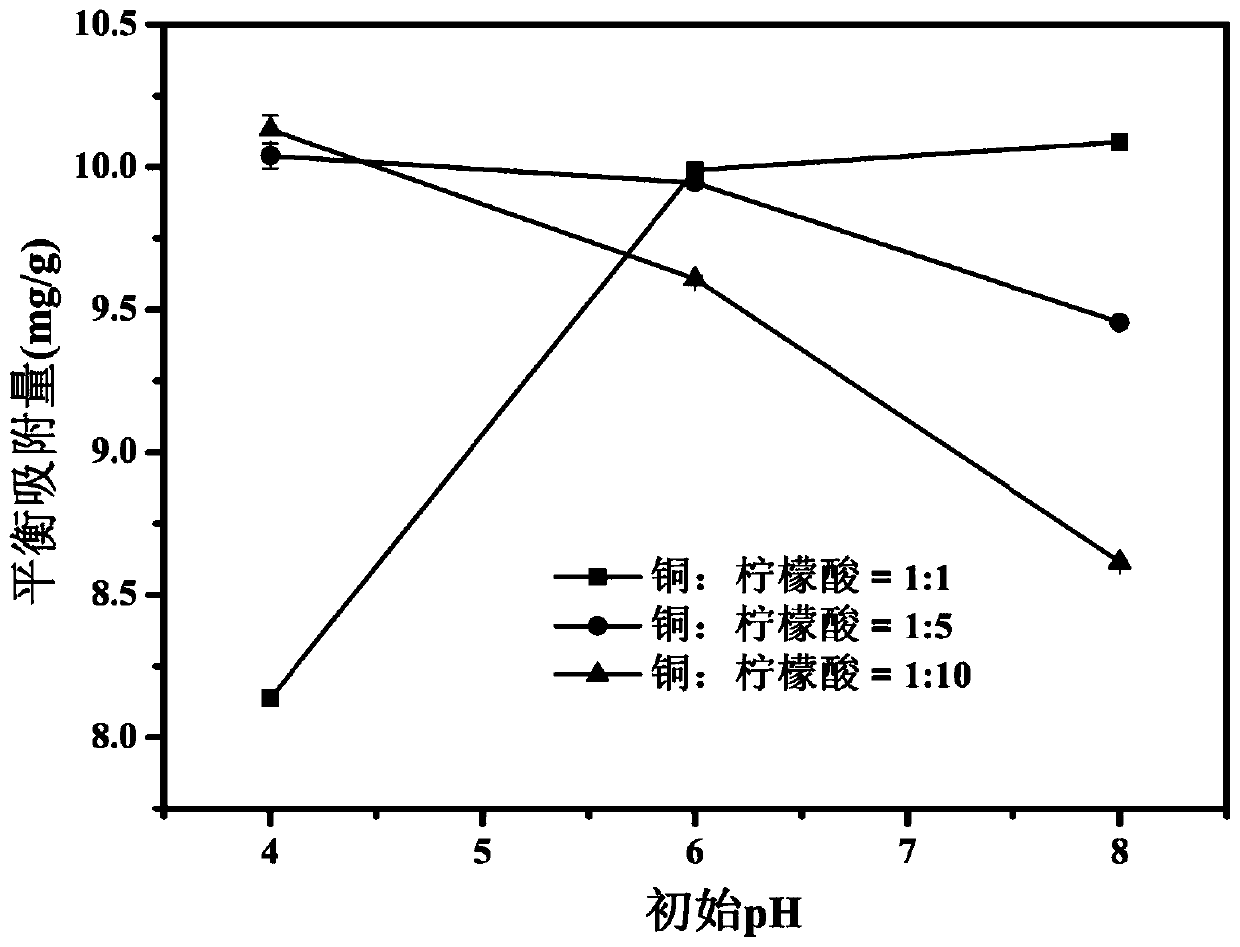

[0070] (a) Prepare simulated waste water containing Cu-citric acid complex, the initial concentration of copper is 2.5mg / L, the molar concentration of citric acid is 5 times of the molar concentration of copper, after filtering, the pH of the raw water is adjusted to 6.0;

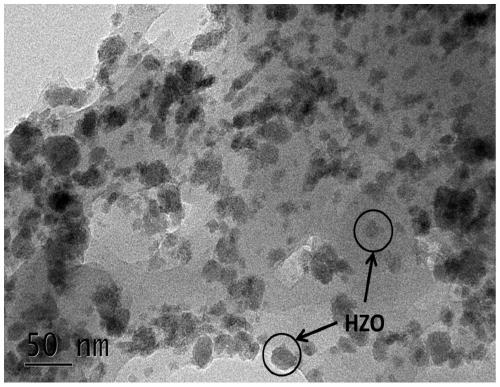

[0071] (b) Simulate the adsorption tower device, the tower is filled with 5mL (wet volume) resin-based nanocomposite material, and the wastewater containing Cu-citric acid complex is passed through the adsorption tower at a temperature of 10°C with a flow rate of 10BV / h. The resin-based nanocomposite material used in this step (b), its matrix macroporous D301 weakly basic ion exchange resin, particle size distribution between 0.6 ~ 0.9mm, pore size distribution between 1 ~ 80nm, rich in Nano-pore structure and tertiary amine groups, nano-hydrated zirconia particles in the resin...

Embodiment 3

[0075] The water body depth of present embodiment 3 removes the method for Cu-citric acid complex, comprises the following steps:

[0076] (a) Prepare simulated waste water containing Cu-citric acid complex, the initial concentration of copper is 5.0mg / L, the molar concentration of citric acid is 10 times of the molar concentration of copper, after filtering, the pH of the raw water is adjusted to 6.0;

[0077] (b) Simulate the adsorption tower device, the tower is filled with 5mL (wet volume) resin-based nanocomposite material, and the wastewater containing Cu-citric acid complex is passed through the adsorption tower at a temperature of 30°C with a flow rate of 1BV / h. The resin-based nanocomposite material used in this step (b), its matrix macroporous D301 weakly basic ion exchange resin, particle size distribution between 0.6 ~ 0.9mm, pore size distribution between 1 ~ 80nm, rich in Nano-pore structure and tertiary amine groups, nano-hydrated zirconia particles in the resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com