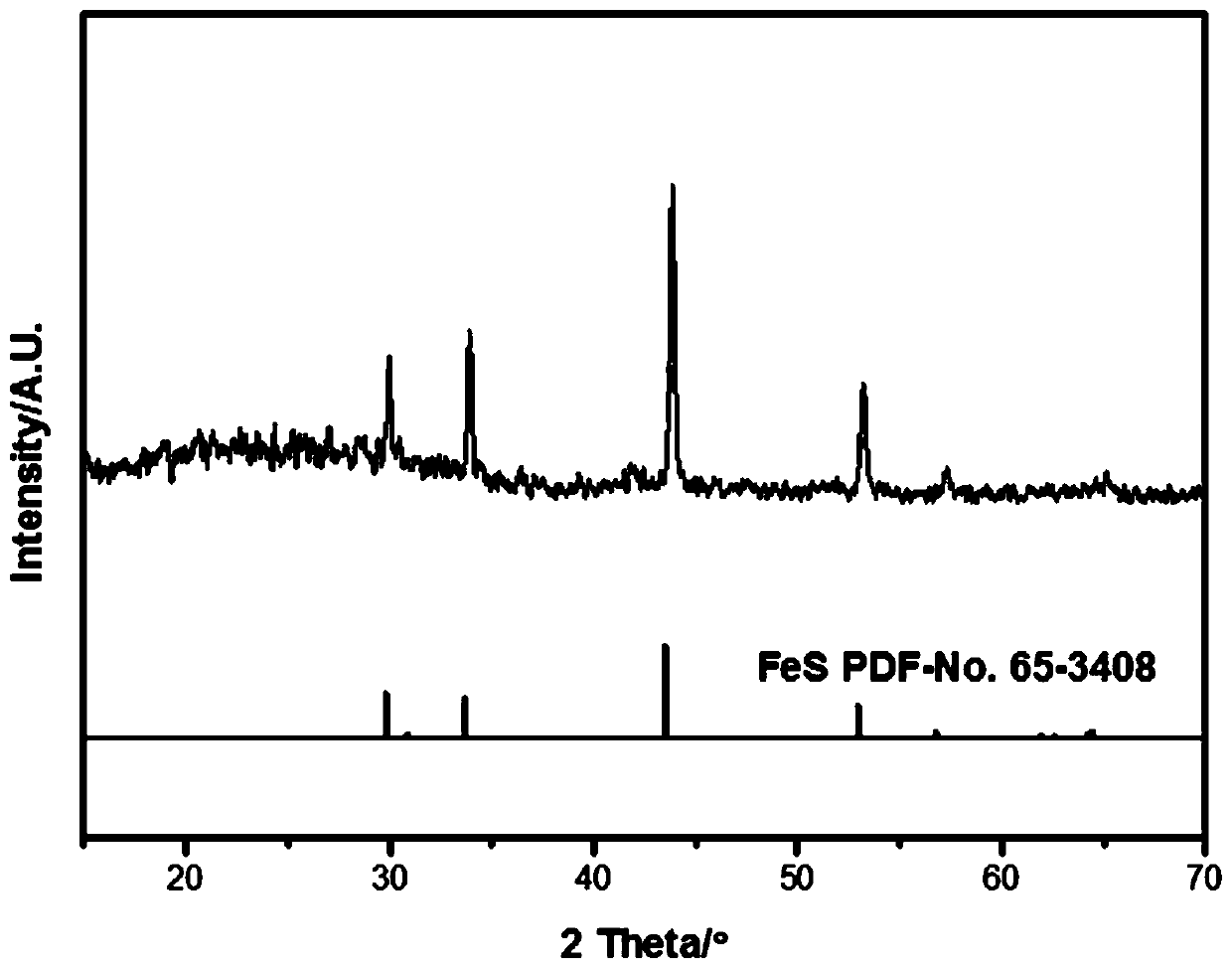

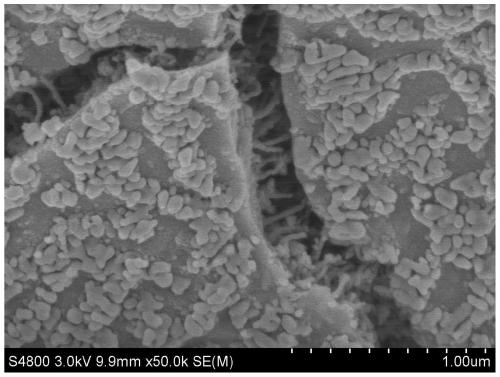

Orientated growth FeS nanomaterial based on carbon cloth, and preparation method and application of FeS nanomaterial

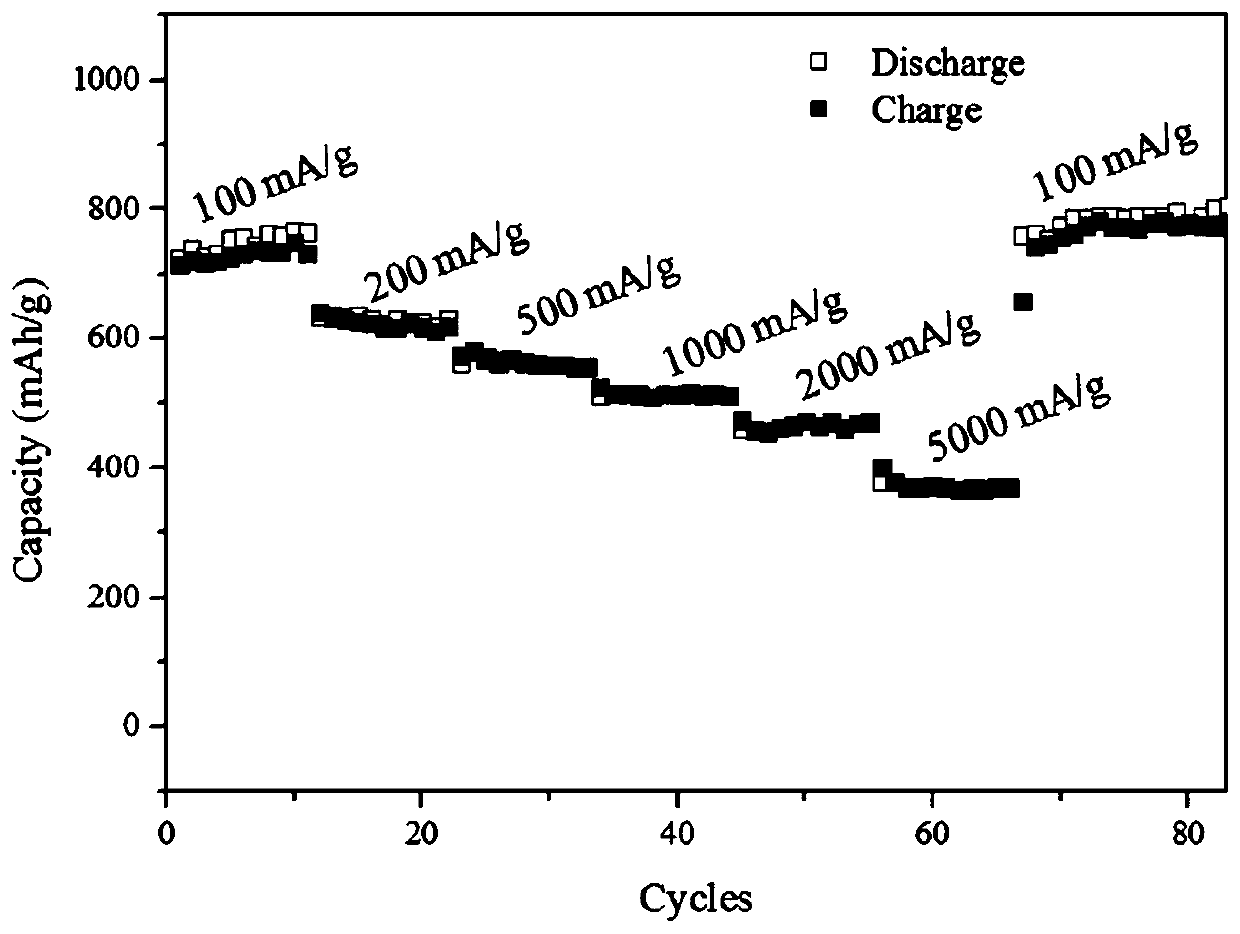

A directional growth and nanomaterial technology, applied in the field of FeS nanomaterials based on carbon cloth directional growth and its preparation, can solve the problem of low utilization rate of effective charging and discharging active points, large microscopic size of electrode materials, hindering electrochemical sodium storage capacity, etc. It can improve the conductivity and structural stability, improve the electrochemical sodium storage performance, and achieve the effect of high capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Take a certain quality of analytically pure ferric ammonium oxalate 2g, urea 4g, mix and grind in a glass mortar to obtain a mixture, and the mixture is denoted as A;

[0031] 2) Take a carbon cloth with a size of about 3cm×6cm and soak it in 25g NH 3 h 2 PO 4 1200ml of water, using the anodic oxidation method, the carbon cloth is treated with electricity at a voltage of 5V for 2 minutes, and then taken out for use;

[0032] 3) Mix mixture A and polyacrylamide at a mass ratio of 3:1, add deionized water, the volume is 20ml, stir for 15min, put the treated carbon cloth into the polytetrafluoroethylene lining, and make the mixture solution Completely immerse the carbon cloth;

[0033] 4) Put the inner liner into the hydrothermal outer kettle, fix and seal it well, and put it into the homogeneous reactor, the reaction temperature range is 250°C, and the reaction time range is 12h;

[0034] 5) After the reaction is over, take out the carbon cloth and put it in a vacu...

Embodiment 2

[0038] 1) Take a certain quality of analytically pure ferric citrate 2g, urea 6g, mix and grind in a glass mortar to obtain a mixture, and the mixture is denoted as A;

[0039] 2) Take a carbon cloth with a size of about 3cm×6cm and soak it in 25g NH 3 h 2 PO 4 1200ml of water, using the anodic oxidation method, the carbon cloth is treated with electricity at a voltage of 5V for 2 minutes, and then taken out for use;

[0040] 3) Mix mixture A and polyacrylamide at a mass ratio of 3:1, add deionized water to a volume of 50ml, stir for 15 minutes and put the treated carbon cloth into the polytetrafluoroethylene lining to make the mixture solution Completely immerse the carbon cloth;

[0041] 4) Put the inner liner into the hydrothermal outer kettle, fix and seal it well, and put it into the homogeneous reactor, the reaction temperature range is 150°C, and the reaction time range is 6h;

[0042] 5) After the reaction is over, take out the carbon cloth and put it in a vacuum o...

Embodiment 3

[0046] 1) Take a certain quality of analytically pure ferric ammonium oxalate 1g, urea 7g, mix and grind in a glass mortar to obtain a mixture, and the mixture is denoted as A;

[0047] 2) Take a carbon cloth with a size of about 3cm×6cm and soak it in 25g NH 3 h 2 PO 41200ml of water, using the anodic oxidation method, the carbon cloth is treated with electricity at a voltage of 5V for 2 minutes, and then taken out for use;

[0048] 3) Mix mixture A and polyacrylamide at a mass ratio of 3:1, add deionized water to a volume of 30ml, stir for 15 minutes and put the treated carbon cloth into the polytetrafluoroethylene lining to make the mixture solution Completely immerse the carbon cloth;

[0049] 4) Put the inner liner into the hydrothermal outer kettle, fix and seal it well, and put it into the homogeneous reactor, the reaction temperature range is 250°C, and the reaction time range is 2h;

[0050] 5) After the reaction is over, take out the carbon cloth and put it in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com