Method for preparing ethanol by using furfural residue and oil-tea-cake as raw materials

A technology of camellia oleifera cake and furfural slag, which is applied in the field of biomass chemistry and chemical industry, to achieve the effects of reducing fermentation cost, low price and reducing use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

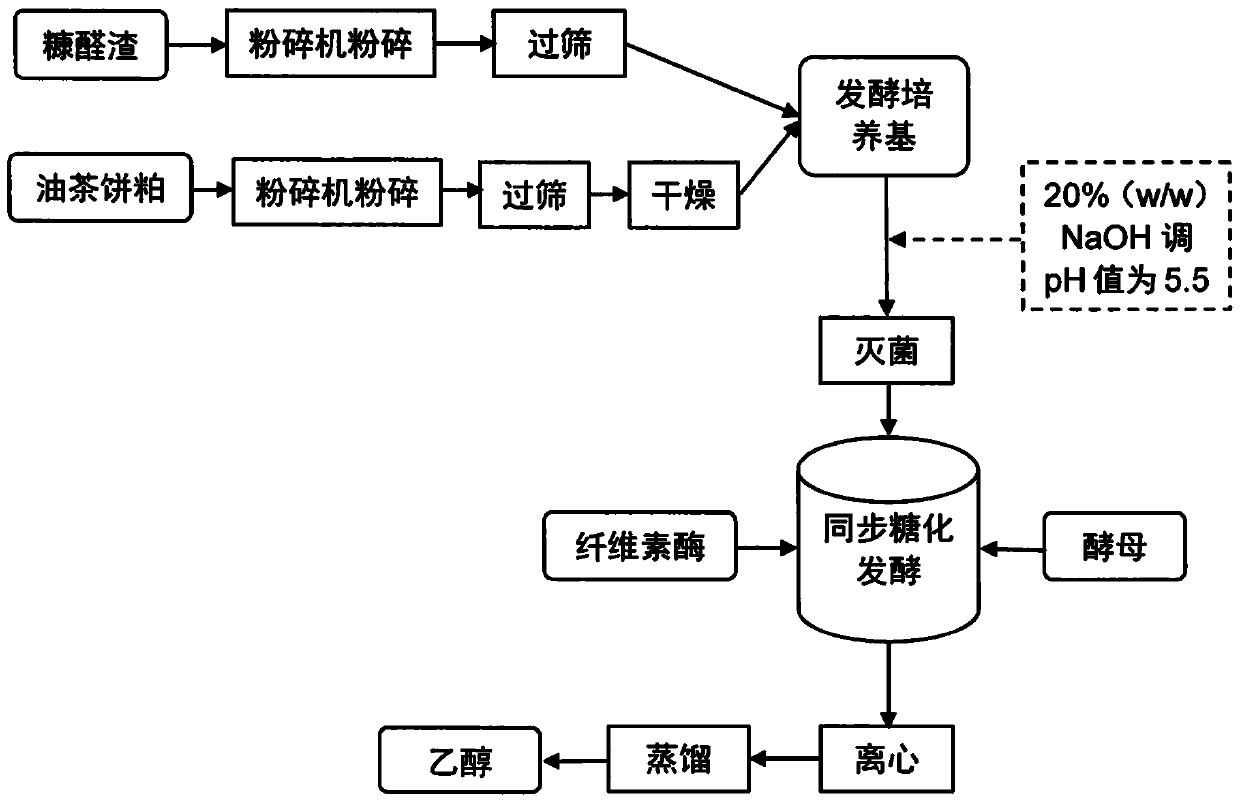

[0025] see process figure 1 .

[0026] 1) Furfural slag is not subjected to any detoxification treatment. It is only pulverized with a pulverizer, sieved through a 40-mesh sieve by an industrial vibrating sieve, and stored in a refrigerator at 4°C for use; After sieving through a 40-mesh sieve, put it in an oven at 50°C for 12 hours, and then put it in a desiccator for later use.

[0027] 2) Activation of yeast: Weigh 6.0 g of dry yeast and dissolve it in a sterilized 2% (w / v) glucose solution, place the mixture in a shaker at 36° C. for 15 minutes, and then shake the shaker The temperature was lowered to 34°C to continue culturing for 1h. After the activation is completed, accurately weigh 8.0 g of yeast cell culture medium, centrifuge at 4000 g for 5 min, discard the supernatant, and resuspend the centrifuged yeast cells with 1.2 mL of sterile water to prepare a 200 g / L high Concentration yeast cell seed solution.

[0028] 3) Preparation of fermentation medium: 10, 20 an...

Embodiment 2

[0031] Under the condition that the addition amount of camellia oleifera cake was 10g / L and the dosage of cellulase was 15FPU / g-cellulose, the effect of substrate concentration (10%, 15% and 20% w / w) on furfural residue and camellia oleifera cake was explored. Effects of mixed substrate fermentation processes. Other parameters of the fermentation process are as described in Example 1.

[0032] When the substrate concentration was 10% (w / w), the ethanol yield was the highest, reaching 93.39% of the theoretical value; when the substrate concentration was increased to 15% (w / w), the ethanol yield decreased slightly (89.89 %); but when the substrate concentration increased to 20% (w / w), the yield of ethanol decreased significantly (61.80%). In order to reduce the process cost of ethanol production and obtain a higher concentration of ethanol, the optimization of the subsequent fermentation process will be carried out on the basis of 15% (w / w) substrate concentration.

Embodiment 3

[0034] On the premise that the addition amount of camellia oleifera cake was 10g / L and the substrate concentration was 15% (w / w), the effect of the amount of cellulase (2.5, 5, 10, 15 FPU / g-cellulose) on the yield of ethanol was investigated. Impact. Other parameters of the fermentation process are as described in Example 1.

[0035] When the enzyme dosage was 10FPU / g-cellulose, the ethanol concentration in the solution was 30.54g / L after 120h of fermentation, and the ethanol yield reached 86.56% of the theoretical value. Compared with the fermentation system (89.89%) with an enzyme dosage of 15 FPU / g-cellulose, the fermentation efficiency was only slightly reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com