Low-sugar high-protein milk drink and processing method thereof

A technology for milk drinks and low-lactose milk, which is applied in the field of low-sugar and high-protein milk drinks and processing thereof, can solve problems such as unfavorable and stable blood sugar, and achieve the effects of high lactose hydrolysis rate, saving production costs and increasing protein content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

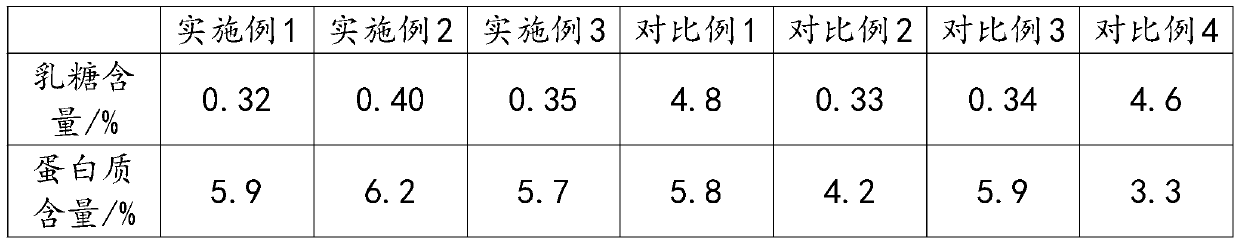

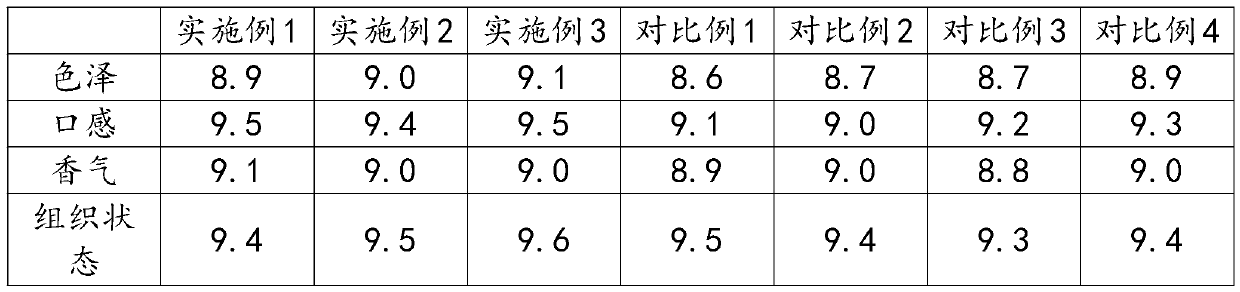

Examples

Embodiment 1

[0057] A low-sugar and high-protein milk beverage, which is made of the following raw materials by weight: 40 parts milk, 10 parts walnut milk, 4 parts soy protein particles, 0.8 parts enzyme preparation, 0.6 parts stabilizer, and 8 parts purified water;

[0058] The milk beverage is made by the following steps:

[0059] The first step is to mix the milk and enzyme preparations, place them in a shaker at 40°C, 200r / min, and shake the reaction for 12 hours, inactivate enzymes in a boiling water bath for 10 minutes, and centrifuge at 12000r / min for 15 minutes to obtain low-lactose milk;

[0060] The second step is to mix low-lactose milk, walnut milk, soy protein particles, stabilizer and purified water evenly;

[0061] The third step is to heat the mixed material liquid to 60°C and homogenize twice under the condition of 25MPa;

[0062] The fourth step is to pour the prepared composite milk beverage into a vacuum degasser with a vacuum strength of 85kPa for degassing;

[0063] The fifth s...

Embodiment 2

[0065] A low-sugar and high-protein milk beverage, which is made of the following raw materials: 45 parts by weight of milk, 12 parts of walnut milk, 4.5 parts of soy protein particles, 0.9 parts of enzyme preparation, 0.7 parts of stabilizers, and 9 parts of purified water;

[0066] The milk beverage is made by the following steps:

[0067] The first step is to mix the milk and enzyme preparations, place them in a shaker at 40°C, 200r / min, and shake the reaction for 12 hours, inactivate enzymes in a boiling water bath for 10 minutes, and centrifuge at 12000r / min for 15 minutes to obtain low-lactose milk;

[0068] The second step is to mix low-lactose milk, walnut milk, soy protein particles, stabilizer and purified water evenly;

[0069] The third step is to heat the mixed material liquid to 63°C and homogenize 2 times under the condition of 25MPa;

[0070] The fourth step is to pour the prepared composite milk beverage into a vacuum degasser with a vacuum strength of 88kPa for degassi...

Embodiment 3

[0073] A low-sugar and high-protein milk beverage, which is made of the following raw materials in parts by weight: 50 parts of milk, 14 parts of walnut milk, 5 parts of soy protein particles, 1 part of enzyme preparation, 0.8 parts of stabilizers, and 10 parts of purified water;

[0074] The milk beverage is made by the following steps:

[0075] The first step is to mix the milk and enzyme preparations, place them in a shaker at 40°C, 200r / min, and shake the reaction for 12 hours, inactivate enzymes in a boiling water bath for 10 minutes, and centrifuge at 12000r / min for 15 minutes to obtain low-lactose milk;

[0076] The second step is to mix low-lactose milk, walnut milk, soy protein particles, stabilizer and purified water evenly;

[0077] The third step is to heat the mixed material to 65°C and homogenize twice under the condition of 25MPa;

[0078] The fourth step is to pour the prepared composite milk beverage into a vacuum degasser with a vacuum strength of 90kPa for degassing; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com