Fungus growing processing technique on osmanthus oolong tea and Fu tea

A processing technology, oolong tea technology, applied in tea processing before extraction, bacteria used in food preparation, food ingredients as antimicrobial preservation, etc., can solve problems such as insufficient innovation, long production cycle, and no similar finished products, and achieve promotion Effects of gastrointestinal motility, regulation of carbohydrate metabolism, and inhibition of production of metabolites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

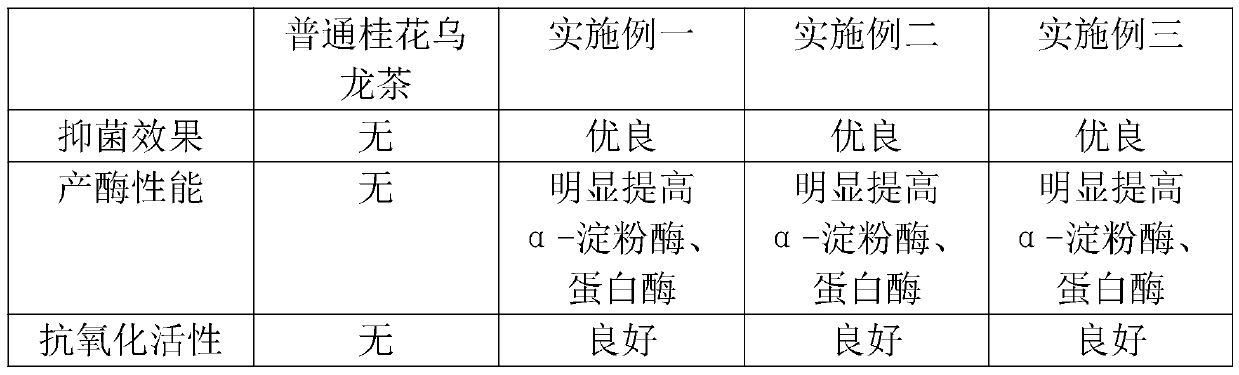

Examples

Embodiment example 1

[0026] A process for producing flowers of osmanthus oolong tea and Fu tea, comprising the following steps:

[0027] (1) Preparation of tea juice strains of Aspergillus grisea:

[0028] Step 1: first purify and identify the Aspergillus grisea, and then store them on a low-temperature slant, prepare the expanded Aspergillus grisea into a bacterial solution and inoculate it on the medium, and obtain a culture of Aspergillus grisea after culturing;

[0029] Step 2: drying the culture of Aspergillus grisea, grinding and sieving after drying, and preparing the finished product to prepare a solid pure strain starter;

[0030] Step 3: Combine the sieved A. griseus culture with KH 2 PO 4 , tea juice, auxiliary bacterial populations and inhibiting mold are prepared according to the mass ratio of 4:0.75:3:1:0.25 to obtain a solid pure strain starter to obtain a solid pure strain starter;

[0031] (2) Treatment of osmanthus oolong tea raw materials: the osmanthus osmanthus oolong tea i...

Embodiment example 2

[0041] A process for producing flowers of osmanthus oolong tea and Fu tea, comprising the following steps:

[0042] (1) Preparation of tea juice strains of Aspergillus grisea:

[0043] Step 1: first purify and identify the Aspergillus grisea, and then store them on a low-temperature slant, prepare the expanded Aspergillus grisea into a bacterial solution and inoculate it on the medium, and obtain a culture of Aspergillus grisea after culturing;

[0044] Step 2: drying the culture of Aspergillus grisea, grinding and sieving after drying, and preparing the finished product to prepare a solid pure strain starter;

[0045] Step 3: Combine the sieved A. griseus culture with KH 2 PO 4 , tea juice, auxiliary bacterial populations and inhibiting mold are prepared according to the mass ratio of 4:0.75:3:1:0.25 to obtain a solid pure strain starter to obtain a solid pure strain starter;

[0046] (2) Treatment of osmanthus oolong tea raw materials: the osmanthus osmanthus oolong tea i...

Embodiment example 3

[0056] A process for producing flowers of osmanthus oolong tea and Fu tea, comprising the following steps:

[0057] (1) Preparation of tea juice strains of Aspergillus grisea:

[0058] Step 1: first purify and identify the Aspergillus grisea, and then store them on a low-temperature slant, prepare the expanded Aspergillus grisea into a bacterial solution and inoculate it on the medium, and obtain a culture of Aspergillus grisea after culturing;

[0059] Step 2: drying the culture of Aspergillus grisea, grinding and sieving after drying, and preparing the finished product to prepare a solid pure strain starter;

[0060] Step 3: Combine the sieved A. griseus culture with KH 2 PO 4 , tea juice, auxiliary bacterial populations and inhibiting mold are prepared according to the mass ratio of 4:0.75:3:1:0.25 to obtain a solid pure strain starter to obtain a solid pure strain starter;

[0061] (2) Treatment of osmanthus oolong tea raw materials: the osmanthus osmanthus oolong tea i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com