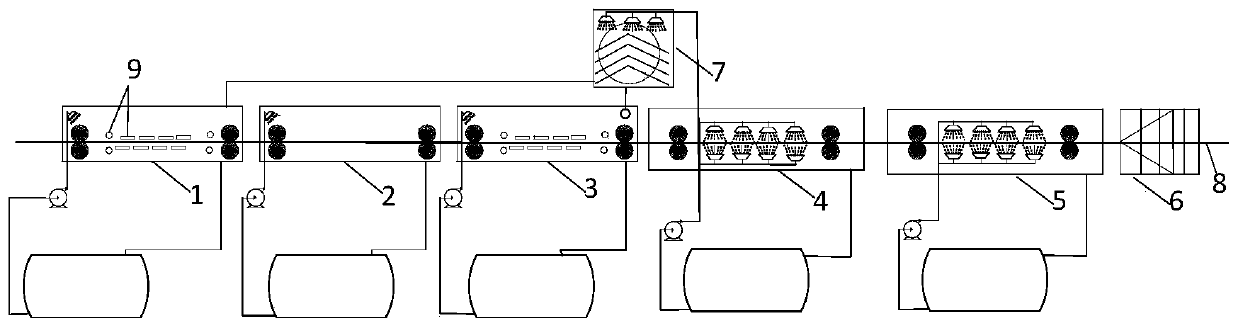

Strip steel efficient descaling device and method

A descaling device and strip steel technology, which is applied in the direction of drying gas arrangement, lighting and heating equipment, workpiece surface treatment equipment, etc., can solve the problems of substandard superheated steam temperature, low recovery rate of hydrochloric acid, insufficient drying of strip steel, etc. , to achieve the effect of reducing the amount of acid mist treatment, alleviating environmental pressure, and reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Open the valves of the pump and circulation tank, and fill the three pickling tanks with liquid. In this embodiment, the scale of the incoming steel grade contains 2.3% silicon, and the thickness of the scale is 18um. It is divided into three layers. The innermost layer is For iron silicon oxide, turn on 12 groups of ultrasonic generators, and the ultrasonic waves will generate instantaneous strong shock waves and micro jets near the surface of the strip, which will peel off the oxide skin on the strip. At the same time, ultrasonic waves will strengthen the replacement of acid solution on the surface of the strip, creating extreme physical and chemical conditions, enhancing the pickling effect and reducing acid consumption;

[0034] 2) The concentration of hydrochloric acid in the three pickling tanks is respectively stable at 4%, 8% and 12%, the temperature of the acid solution is 60° C., and the rinsing temperature is 40° C. to clean the strip steel. The process imp...

Embodiment 2

[0038] 1) Open the valves of the pump and circulation tank, and fill the three acoustic pickling tanks with liquid. In this embodiment, the incoming steel scale contains 2.3% silicon and 2% manganese, and the thickness of the oxide scale is 16um, which is divided into three layers. Outer Fe 3 o 4 The thickness is 8.65um, the thickness of the middle layer FeO is 5.57um, and the innermost layer is iron silicon oxide. Turn on 9 sets of ultrasonic generators, and the ultrasonic waves will generate instantaneous strong shock waves and micro jets near the surface of the strip, making the strip on the peeling off of oxide skin. At the same time, ultrasonic waves will strengthen the replacement of acid solution on the surface of the strip, creating extreme physical and chemical conditions, enhancing the pickling effect and reducing acid consumption;

[0039] 2) The concentrations of hydrochloric acid in the three pickling tanks are respectively stable at 6%, 10% and 11%, the tempera...

Embodiment 3

[0043] 1) Open the valves of the pump and circulation tank, and fill the three pickling tanks with liquid. In the present embodiment, the scale thickness of ordinary carbon steel in the scale of incoming steel is 21um, which is divided into a typical three-layer scale structure. Turn on 8 sets of ultrasonic transmitters, and the ultrasonic waves will generate instantaneous strong shock waves and micro jets near the surface of the strip, which will peel off the oxide skin on the strip. At the same time, ultrasonic waves will strengthen the replacement of acid solution on the surface of the strip, creating extreme physical and chemical conditions, enhancing the pickling effect and reducing acid consumption;

[0044] 2) The concentration of hydrochloric acid in the three pickling tanks is respectively stable at 2%, 6% and 14%, the temperature of the acid solution is 85° C., and the rinsing temperature is 60° C. to clean the strip steel. The process implementation parameters are as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com