Ultra-low-energy consumption flash evaporation concentration system for zero discharge of desulfurization wastewater and industrial salty wastewater

A technology for flash evaporation and concentration of salty wastewater, which is used in heating water/sewage treatment, gaseous discharge wastewater treatment, etc. And nozzle fouling and other problems, to achieve the effect of waste reuse, small footprint, and avoid corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

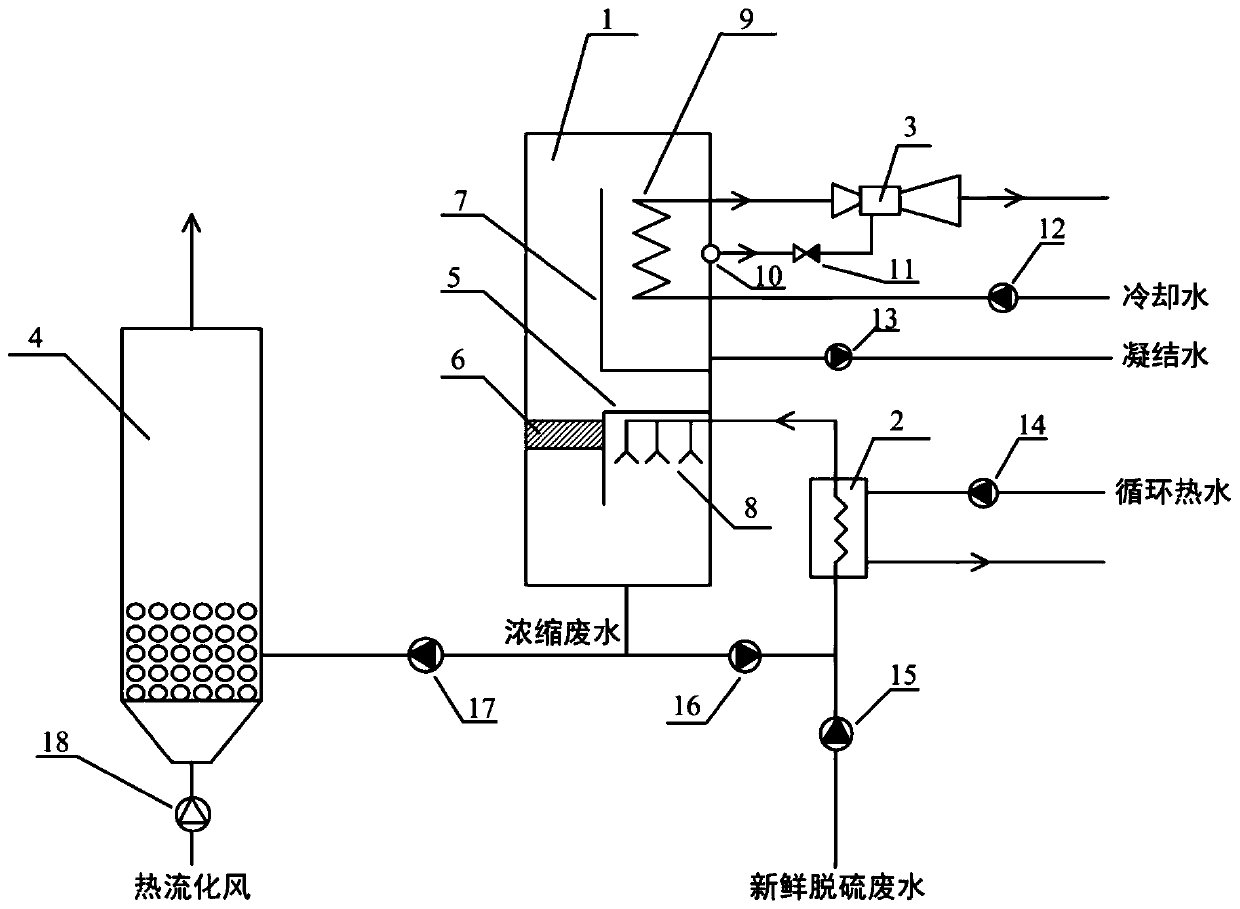

[0030] An ultra-low energy consumption flash concentrated desulfurization wastewater and industrial saline wastewater zero discharge system proposed by the present invention, as shown in the attached figure 1As shown, it includes a flash concentrator 1 , a water-to-water heat exchanger 2 , an ejector 3 and a fluidized bed dryer 4 . The liquid inlet of the flash concentrator 1 is connected with the refrigerant outlet of the water-water heat exchanger 2, and the refrigerant of the water-water heat exchanger 2 is the fresh saline waste water from the desulfurization tower and the concentrated waste water of the flash concentrator. Mixed water, the inlet of the ejector 3 is connected to the cooling water outlet of the flash concentrator 1, the suction chamber of the ejector 3 is connected to the exhaust port 11 of the flash concentrator 1, the liquid inlet of the fluidized bed dryer 4 It is connected with the concentrated waste water outlet of the flash concentrator 1.

[0031] T...

Embodiment 2

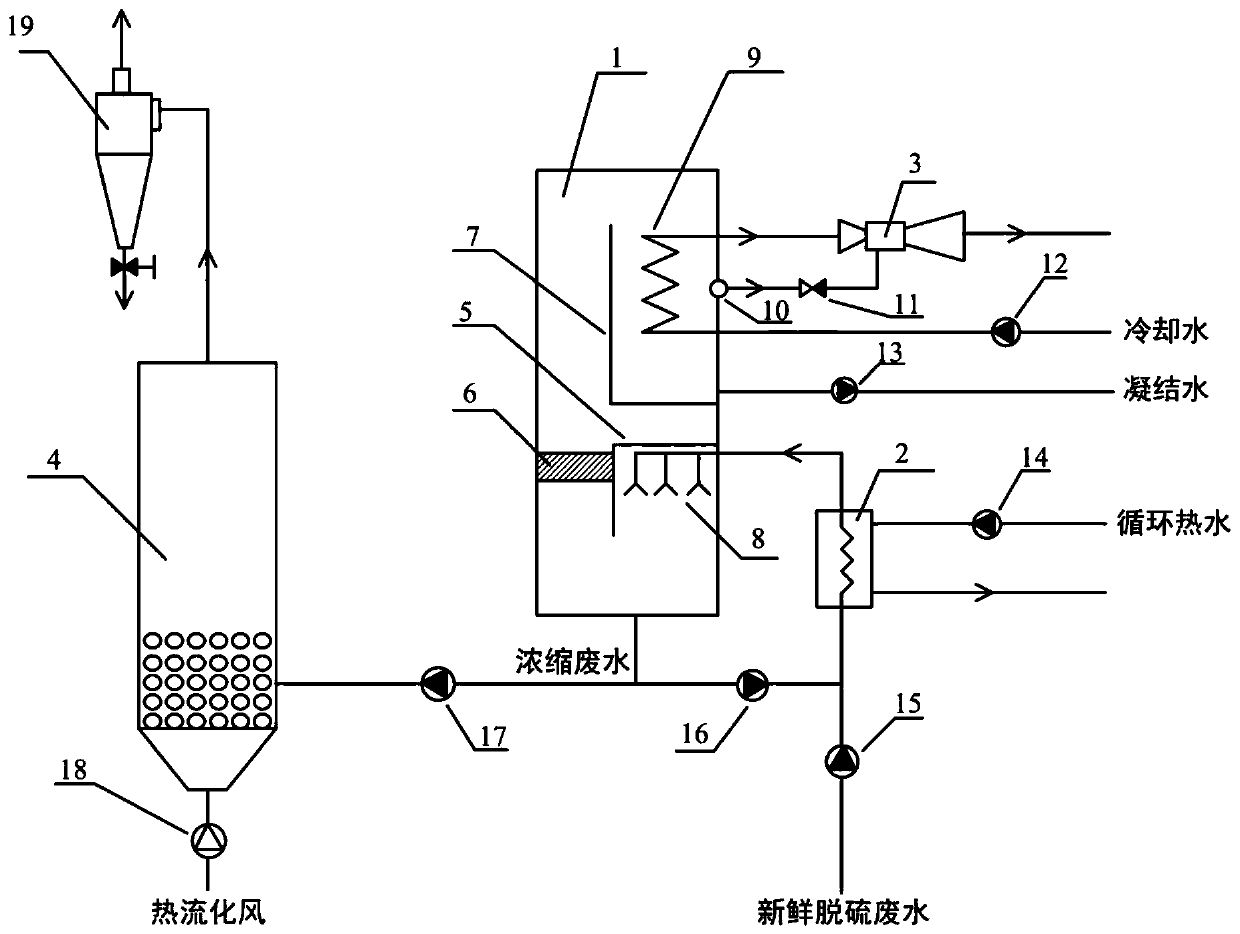

[0036] An ultra-low energy consumption flash concentrated desulfurization wastewater and industrial saline wastewater zero discharge system proposed by the present invention has basically the same structure as that of the system in Example 1, the difference is that the desulfurization wastewater dried by the fluidized bed drier Crystalline salts are collected in different forms, such as attached figure 2 As shown, it is specifically: the desulfurization waste water crystalline salt dried in the fluidized bed drier 4 enters the cyclone separator 19 from the top outlet of the fluidized bed drier 4 together with the fluidized wind, and the top outlet of the fluidized bed drier 4 It communicates with the inlet of the cyclone separator, and the gas outlet of the cyclone separator 19 communicates with the inlet of the dust collector, and the crystallized salt is discharged from the bottom discharge port of the cyclone separator for recycling and selling.

Embodiment 3

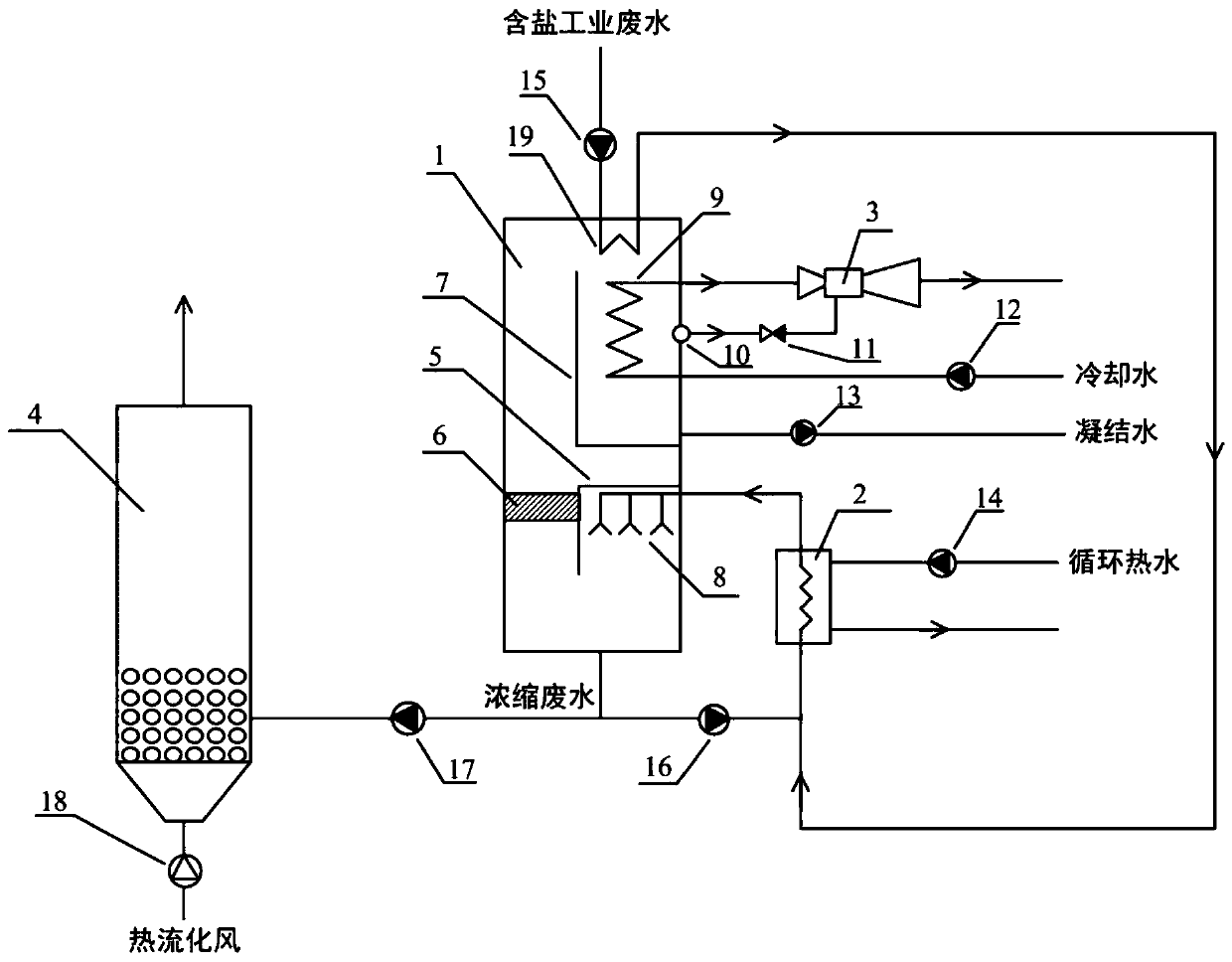

[0038] An ultra-low energy consumption flash concentrated desulfurization wastewater and industrial saline wastewater zero discharge system proposed by the present invention has basically the same structure as the system in Example 1, the difference is that the wastewater is saline industrial wastewater, Before the described saline industrial wastewater enters the water heat exchanger 2, it is preheated through the flash concentrator 1, as attached image 3 As shown, it is specifically: above the condenser 9 in the flash concentrator 1, a heat exchanger 19 is arranged, the inlet of the heat exchanger 19 is connected to the outlet of the feed water pump 15, and the inlet of the feed water pump 15 is connected to the salty water produced by other industrial processes. For industrial waste water, the outlet of the heat exchanger 19 and the outlet of the circulating water pump 16 are connected to the refrigerant inlet of the water-water heat exchanger 2 after merging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com