Preparation method of phenyl bis (2,4,6-trimethylbenzoyl) phosphine oxide

A technology of trimethylbenzoyl and trimethylbenzoyl chloride, applied in the field of preparation of phenyl bisphosphine oxide, can solve the problems of low yield and poor catalytic effect, and achieve high yield and high yield , high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

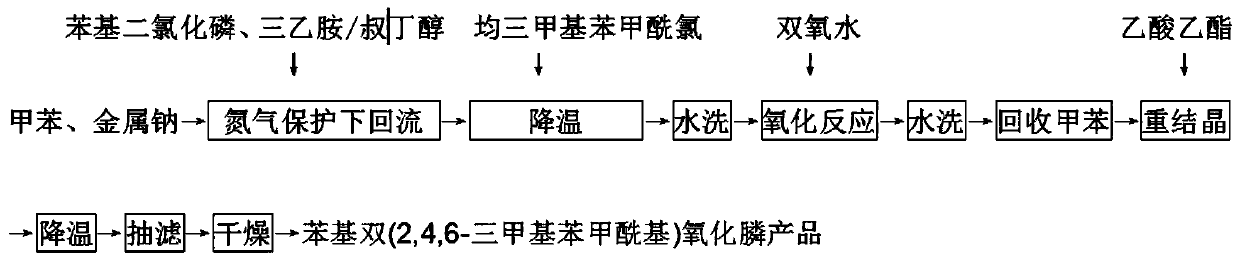

Method used

Image

Examples

Embodiment 1

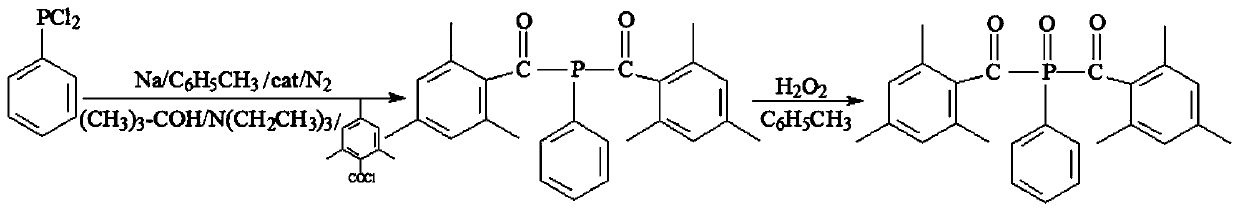

[0033] The present invention uses phenyl phosphorus dichloride as the starting material, replaces chlorine with powdery metal sodium in the presence of nitrogen, then reduces and condenses with 2,4,6-trimethylbenzoyl chloride under weakly alkaline conditions And oxidation reaction prepares phenyl bis (2,4,6-trimethylbenzoyl) phosphine oxide product; Specifically this embodiment comprises the following steps:

[0034] Step 1. Open the nitrogen valve, pass nitrogen gas into the synthesis reaction kettle respectively, and add 400kg of toluene into the synthesis reaction kettle after the bubbler bubbles. Heat up with water until no water drops drop, cool down, add 1.1mol of sodium metal and 0.03mol of catalyst (the catalyst is a mixture of potassium tert-butoxide and serine, and the mol ratio of potassium tert-butoxide and serine is 5:1), continue to heat up until the metal sodium is completely dissolved and keep the reaction for 3 hours, add 1.0mol of phenylphosphorous dichloride...

Embodiment 2

[0040] Step 1. Open the nitrogen valve, pass nitrogen gas into the synthesis reaction kettle respectively, and add 500kg of toluene into the synthesis reaction kettle after the bubbler bubbles. Heat up with water until no water droplets drop, cool down, add 1mol of sodium metal and 0.01mol of catalyst (the catalyst is a mixture of potassium tert-butoxide and serine, and the mol ratio of potassium tert-butoxide and serine is 4 : 1), continue to heat up until metal sodium is completely dissolved and keep warm for 3 hours, add 0.8 mol of phenylphosphorous dichloride dropwise, control the temperature at 90° C., keep warm for 4 hours.

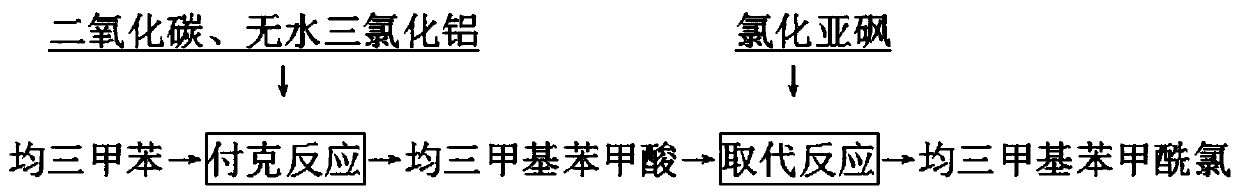

[0041] Step 2. Preparation of 2,4,6-trimethylbenzoyl chloride: Add 2 mol of anhydrous aluminum chloride into 5.3 mol of mesitylene, stir, and feed 1 mol of CO at 26-30°C 2 After 8-10 hours, slowly drop the reacted feed liquid into the hydrolysis kettle equipped with dilute hydrochloric acid, the temperature should not exceed 80°C, after the hydroly...

Embodiment 3

[0046] Step 1. Open the nitrogen valve, pass nitrogen gas into the synthesis reaction kettle respectively, and add 600kg of toluene into the synthesis reaction kettle after the bubbler bubbles. Warming up with water until no water drops drop, cooling, adding 1.5mol of sodium metal and 0.05mol of catalyzer (the catalyzer is a mixture of potassium tert-butoxide and serine, and the mol ratio of potassium tert-butoxide and serine is 6:1), continue to heat up until the metal sodium is completely dissolved and keep the reaction for 3 hours, add 1.2mol of phenylphosphorous dichloride dropwise, control the temperature at 120°C, and keep the reaction for 4 hours.

[0047] Step 2. Preparation of 2,4,6-trimethylbenzoyl chloride: Add 2 mol of anhydrous aluminum chloride into 5.3 mol of mesitylene, stir, and feed 1 mol of CO at 26-30°C 2 After 8-10 hours, slowly drop the reacted feed liquid into the hydrolysis kettle equipped with dilute hydrochloric acid, the temperature should not excee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com