Environment-friendly high-wear-resistant water-based varnish and preparation method thereof

A water-based varnish and high wear-resistant technology, which is applied to biocide-containing paints, antifouling/underwater coatings, coatings, etc., can solve the problem that the wear resistance cannot achieve the desired effect, the wear resistance of water-based varnishes decreases, Wax emulsion particles fall off and other problems, to achieve low production cost, good anti-blocking performance, and good cohesive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

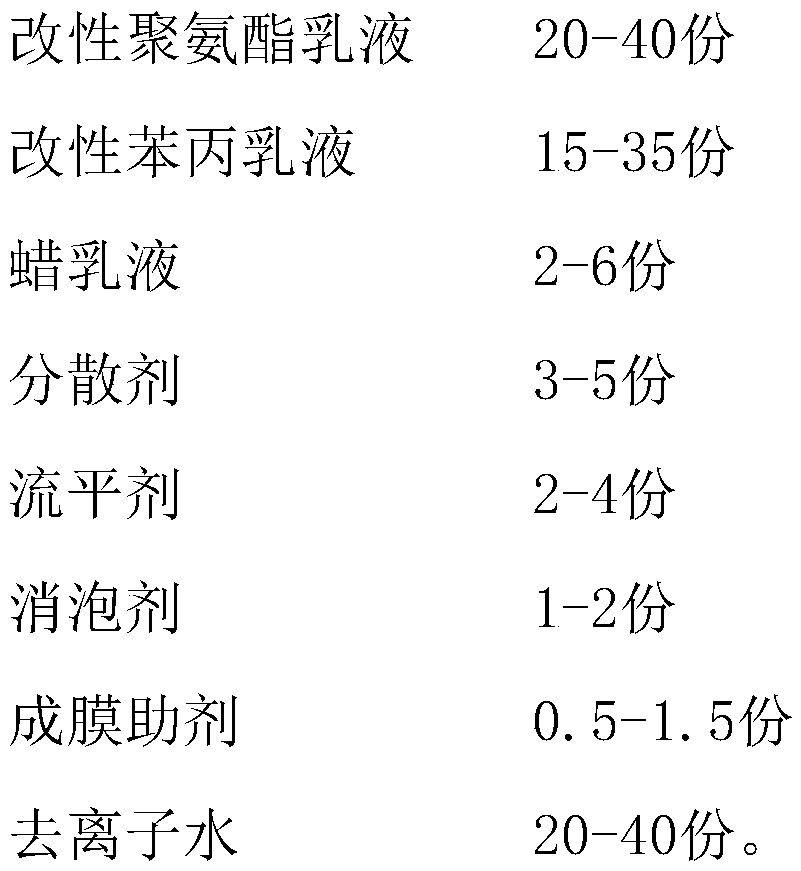

[0026] An environment-friendly and highly wear-resistant water-based varnish, comprising the following raw materials in parts by weight:

[0027]

[0028] The preparation method of the modified polyurethane emulsion is as follows: adding the initiator and maleic anhydride to the aqueous polyurethane emulsion, dispersing with a homogenizer at a temperature of 80° C. for 1.5 hours, and filtering to obtain a modified polyurethane emulsion; wherein, the initiator is added The amount is 60% of the quality of the water-based polyurethane emulsion, and the amount of maleic anhydride added is 30% of the quality of the water-based polyurethane emulsion.

[0029] The preparation method of the modified styrene-acrylic emulsion is as follows: dissolving the emulsifier in deionized water to obtain a pre-reaction solution; taking part of the pre-reaction solution and adding acrylate monomers to high-speed stirring for 20 minutes to obtain a reaction solution A; Mix the reaction solution ...

Embodiment 2

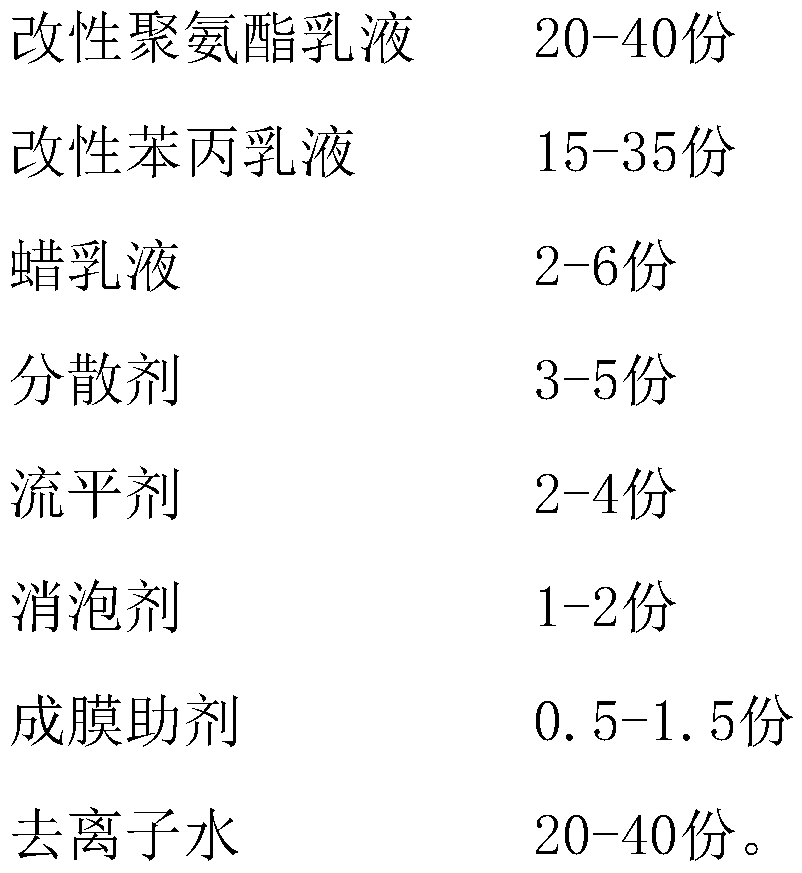

[0038] An environment-friendly and highly wear-resistant water-based varnish, comprising the following raw materials in parts by weight:

[0039]

[0040] The preparation method of the modified polyurethane emulsion is as follows: adding the initiator and maleic anhydride to the water-based polyurethane emulsion, using a homogenizer to disperse for 1.2 hours at a temperature of 82° C., and filtering to obtain a modified polyurethane emulsion; wherein, the initiator is added The amount is 65% of the quality of the water-based polyurethane emulsion, and the amount of maleic anhydride added is 35% of the quality of the water-based polyurethane emulsion.

[0041] The preparation method of the modified styrene-acrylic emulsion is as follows: dissolving the emulsifier in deionized water to obtain a pre-reaction solution; taking part of the pre-reaction solution and adding acrylate monomer to high-speed stirring for 25 minutes to obtain a reaction solution A; Mix the reaction solu...

Embodiment 3

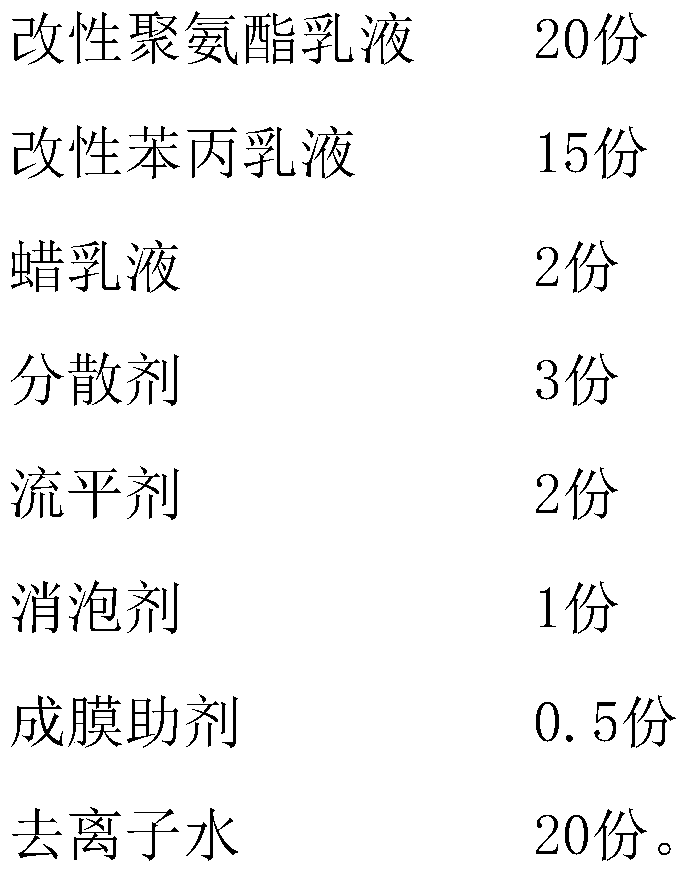

[0050] An environment-friendly and highly wear-resistant water-based varnish, comprising the following raw materials in parts by weight:

[0051]

[0052] The preparation method of the modified polyurethane emulsion is as follows: adding the initiator and maleic anhydride to the water-based polyurethane emulsion, using a homogenizer to disperse for 1 hour at a temperature of 85° C., and filtering to obtain the modified polyurethane emulsion; wherein, the amount of the initiator added It is 70% of the quality of the water-based polyurethane emulsion, and the addition of maleic anhydride is 40% of the quality of the water-based polyurethane emulsion.

[0053] The preparation method of the modified styrene-acrylic emulsion is as follows: dissolving the emulsifier in deionized water to obtain a pre-reaction solution; taking part of the pre-reaction solution and adding acrylate monomers to high-speed stirring for 30 minutes to obtain a reaction solution A; The reaction solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com