Buffer anti-cracking layer, its preparation method, concrete pavement structure and its preparation method

An anti-crack layer, cement concrete technology, applied in the field of cement concrete pavement, can solve problems such as stress and deformation not being effectively diffused, warping deformation of concrete panels, failure to reach the design service life, etc., to avoid expansion-shrinkage- Expansion cycles, resistance to shrinkage and cracking, protection against erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The method according to the present invention prepared cracking buffer layer 2 comprising the steps of:

[0039] Weigh cement, coarse aggregate, sand, admixture, modifiers, additives and water, and then cement, coarse aggregate, sand, admixtures, and water-modified stir, followed by addition of additives, stirred uniformly to obtain cracking material of the buffer layer 2, finally prepared using crack buffer layer of the buffer material 2 2 anti-crack layer.

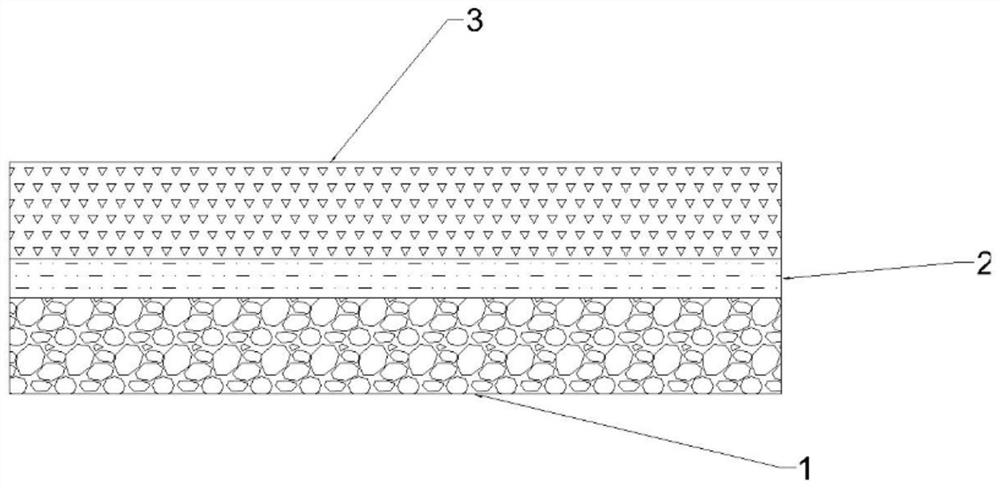

[0040] Cracking buffer cement concrete pavement structure according to the present invention comprises a base 1, cement concrete road surface 3 and disposed on the surface of cement concrete pavement crack resistance layer 3 and the buffer layer between the base layer 1 2, wherein said buffer cracking thickness of the layer 2 is 2.5 ~ 3.0cm.

[0041] The method of the present invention, the buffer prepared crack concrete pavement structure, comprising the steps of:

[0042]1) According to the "Rules of Highway Cement ...

Embodiment 1

[0047] The buffer anti-crack layer 2 of the present invention is from 100 parts of cement, 120 parts of coarse agglomeration, and 10 parts of sand, 25 parts of the blend, 10 parts of modifier, 3 parts. Excess additives and 40 parts of water;

[0048] The blend is composed of bentonite, wheat stone, sea bubble powder and expansive pearl rock;

[0049] The modifier blend is composed of polybutadiene, polystyrene latex and neoprene latex;

[0050] The appliance consists of high water absorbing resin, nanocalized calcium oxide, magnesium powder, calcium sulphate, N-diethyl nitromine, and polycarboxylic acid water repellent.

[0051] Cement is 42.5r cement or 52.5r ordinary silicate cement, the density of cement is 3.0g / cm 3 .

[0052] The fineness modulus of the river sand is 2.5, the density of the river sand is greater than or equal to 2550kg / m 3 .

[0053] The coarse fracture is lime rock, and the percentage of 30 mm of the crude collector is 0, the 9.5mm screen hole of the cru...

Embodiment 2

[0066] The buffer anti-crack layer 2 of the present invention is from 100 parts of cement, 160 parts of a coarse material, 180 parts of sand, and 6 serviles. Extractures and 50 parts of water;

[0067] The blend is composed of bentonite, wheat stone, sea bubble powder and expansive pearl rock;

[0068] The modifier blend is composed of polybutadiene, polystyrene latex and neoprene latex;

[0069] The appliance consists of high water absorbing resin, nanocalized calcium oxide, magnesium powder, calcium sulphate, N-diethyl nitromine, and polycarboxylic acid water repellent.

[0070] Cement is 42.5r cement or 52.5r ordinary silicate cement, the density of cement is 3.3g / cm 3 .

[0071] The fineness modulus of the river sand is 3.0, the apparent density of the river sand is greater than or equal to 2550kg / m 3 .

[0072] The coarse fracture is lime rock, and the 16.0mm screen hole of crude collector is 0, and the percentage of 9.5mm screen hole of crude collector is 15%, and the 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com