Environmental protection aqueous stone-imitation screen printing ink, and preparation technology and applications thereof

A water-based, stone silk technology, applied in the field of printing ink, can solve the problems of easy falling off, printing ink cracking, etc., and achieve the effects of good ductility, easy printing, and convenient operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

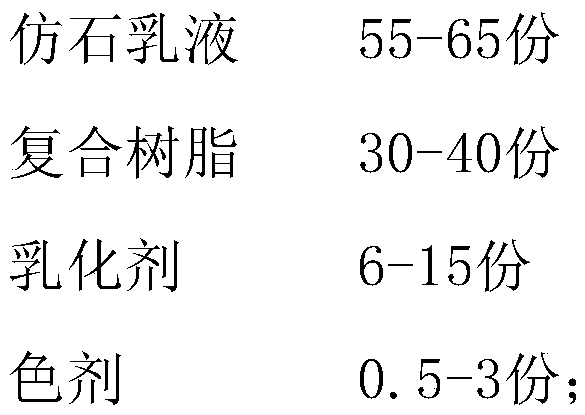

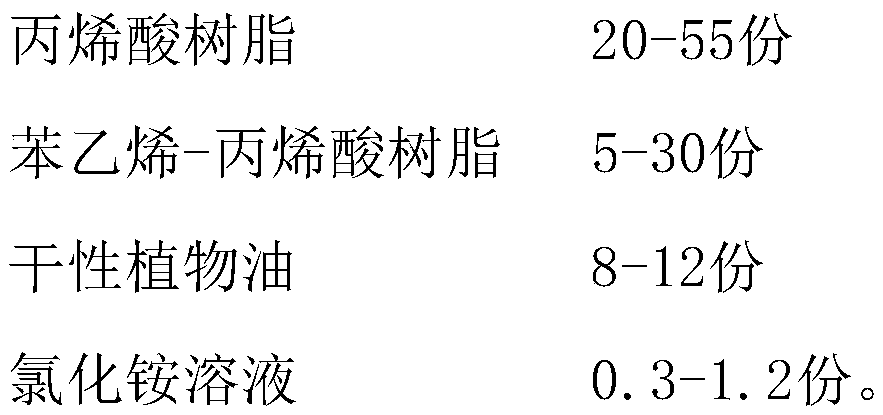

[0044] An environmentally friendly water-based imitation stone screen printing ink, comprising the following raw materials in parts by weight:

[0045]

[0046] The emulsifier is nonylphenol polyether-6 phosphate sodium salt.

[0047] The colorant is benzidine yellow G.

[0048] Every part of described imitation stone emulsion comprises the raw material of following weight part:

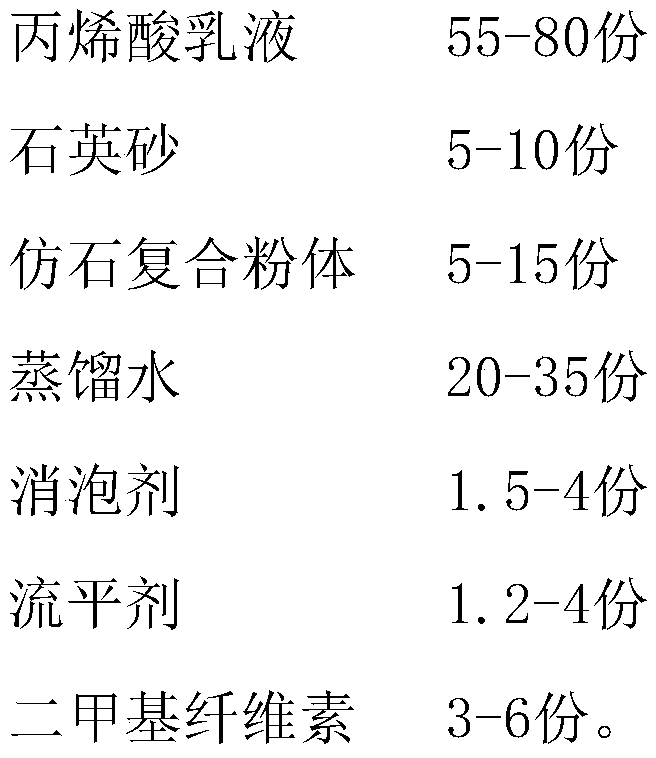

[0049]

[0050] The particle size of the quartz sand is 0.01mm; the imitation stone composite powder is a mixture of limestone, kaolin, wollastonite and clay powder in a weight ratio of 2:4:2.5:1; the defoamer It is polyoxypropylene polyoxyethylene glyceryl ether; the leveling agent is polydimethylsiloxane.

[0051] Described imitation stone emulsion is made by following steps:

[0052] (1) According to parts by weight, mix and stir each material forming the imitation stone composite powder evenly, and set aside;

[0053] (2) According to parts by weight, the distilled water and the imitati...

Embodiment 2

[0066] An environmentally friendly water-based imitation stone screen printing ink, comprising the following raw materials in parts by weight:

[0067]

[0068]

[0069] The emulsifier is triethanolamine monooleate.

[0070] The colorant is golden red.

[0071] Every part of described imitation stone emulsion comprises the raw material of following weight part:

[0072]

[0073] The particle size of the quartz sand is 0.03mm; the imitation stone composite powder is a mixture of limestone, kaolin, wollastonite and clay powder in a weight ratio of 3:3.5:2.8:1; the defoamer It is polydimethylsiloxane; the leveling agent is polymethylphenylsiloxane.

[0074] Described imitation stone emulsion is made by following steps:

[0075] (1) According to parts by weight, mix and stir each material forming the imitation stone composite powder evenly, and set aside;

[0076] (2) According to parts by weight, the distilled water and the imitation stone composite powder uniformly ...

Embodiment 3

[0089] An environmentally friendly water-based imitation stone screen printing ink, comprising the following raw materials in parts by weight:

[0090]

[0091] The emulsifier is nonylphenol polyether-6 phosphate sodium salt.

[0092] The colorant is phthalocyanine blue.

[0093] Every part of described imitation stone emulsion comprises the raw material of following weight part:

[0094]

[0095] The particle diameter of described quartz sand is 0.05mm; Described imitation stone composite powder is the mixture that is composed of limestone, kaolin, wollastonite, potter's clay powder with a weight ratio of 3.5:3:3:1; The defoamer It is polyoxypropylene polyoxyethylene glyceryl ether; the leveling agent is polymethylphenylsiloxane.

[0096] Described imitation stone emulsion is made by following steps:

[0097] (1) According to parts by weight, mix and stir each material forming the imitation stone composite powder evenly, and set aside;

[0098] (2) According to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com