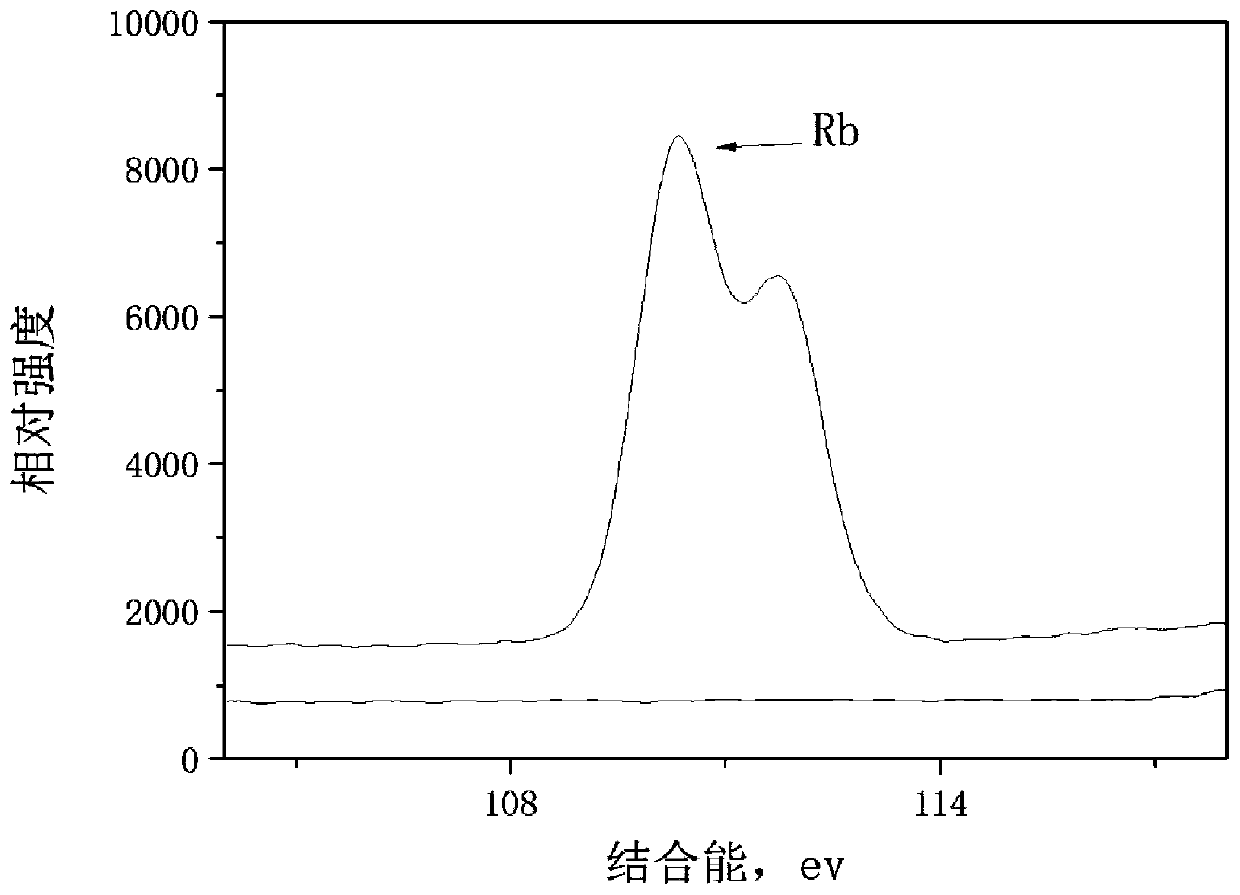

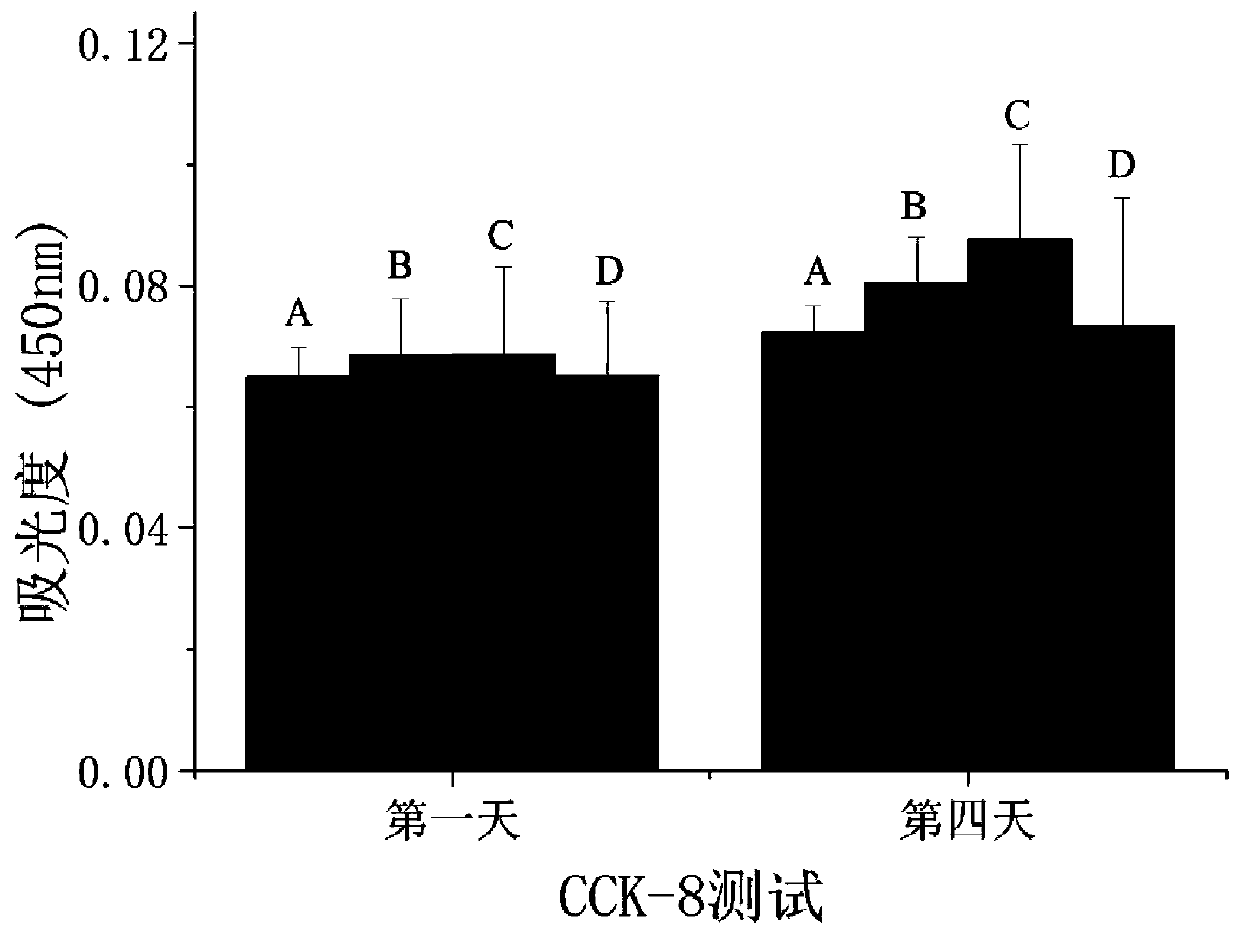

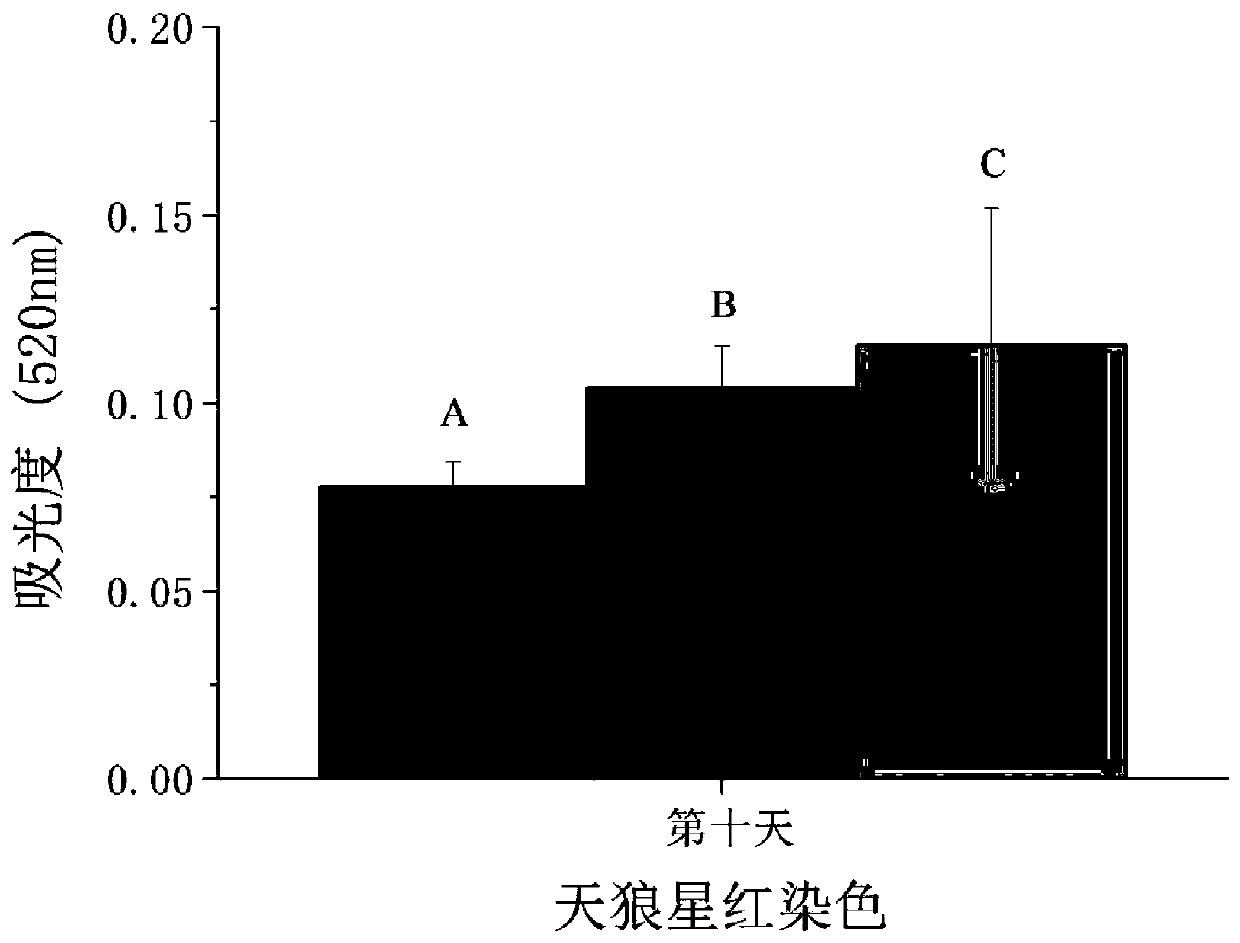

Antibacterial osteogenesis-promoting rubidium titanium tantalum composite material and preparation method and application thereof

A composite material, bone-promoting technology, used in medical science, prosthesis, tissue regeneration, etc., can solve the problems of poor biological activity, surgical failure, poor antibacterial properties, etc., achieve good biocompatibility, and solve the incompatibility of biocompatibility. The effect of good and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Prepare titanium-tantalum alloy powder, wherein in the titanium-tantalum alloy powder, according to the atomic ratio, titanium: tantalum = 1:20; then place the titanium-tantalum alloy powder in a cold isostatic press for compression molding, and the compression pressure is 200MPa , the pressing time is 4min, and then the pressed green body is sintered in vacuum sintering, and the vacuum degree is controlled to be 10 -4 Pa, the vacuum sintering temperature is 1200°C, the sintering time is 2h, and the heating rate is 45°C / min.

[0048] The titanium-tantalum composite material is subjected to sandblasting treatment, and then placed in an acid solution for acid treatment at 65°C for 24 hours, wherein the acid solution is composed of hydrochloric acid (mass fraction: 38% to write the specific value), sulfuric acid (mass fraction: 96% to write the specific value ) mixed with water in a volume ratio of 1:1:1.17. Put the acid-treated titanium-tantalum composite material in 4M ...

Embodiment 2

[0077] Prepare titanium-tantalum alloy powder, wherein in the titanium-tantalum alloy powder, according to the atomic ratio, titanium: tantalum = 1:20; then place the titanium-tantalum alloy powder in a cold isostatic press for compression molding, and the compression pressure is 180MPa , the pressing time is 3min, and then the pressed green body is sintered in vacuum sintering, and the vacuum degree is controlled to be 10 -4 Pa, the vacuum sintering temperature is 1300°C, the sintering time is 2h, and the heating rate is 50°C / min.

[0078] The titanium-tantalum composite material was sandblasted, and then placed in an acid solution for acid treatment at 65°C for 24 hours, wherein the acid solution was composed of hydrochloric acid (mass fraction: 37%), sulfuric acid (mass fraction: 95%) and water in a volume ratio of 1:1:1.4 mixed to obtain. Put the acid-treated titanium-tantalum composite material in 5M sodium hydroxide solution, and perform alkali heat treatment at 60°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com