System and method for recycling ferrous ion-containing acidic waste water resources

A technology for acid wastewater and resource recovery, applied in the field of environmental engineering, can solve the problems of high cost, inability to realize the recovery and utilization of acid wastewater resources, sludge reduction and stabilization, secondary pollution, etc. Precipitation stabilization and immobilization disposal, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

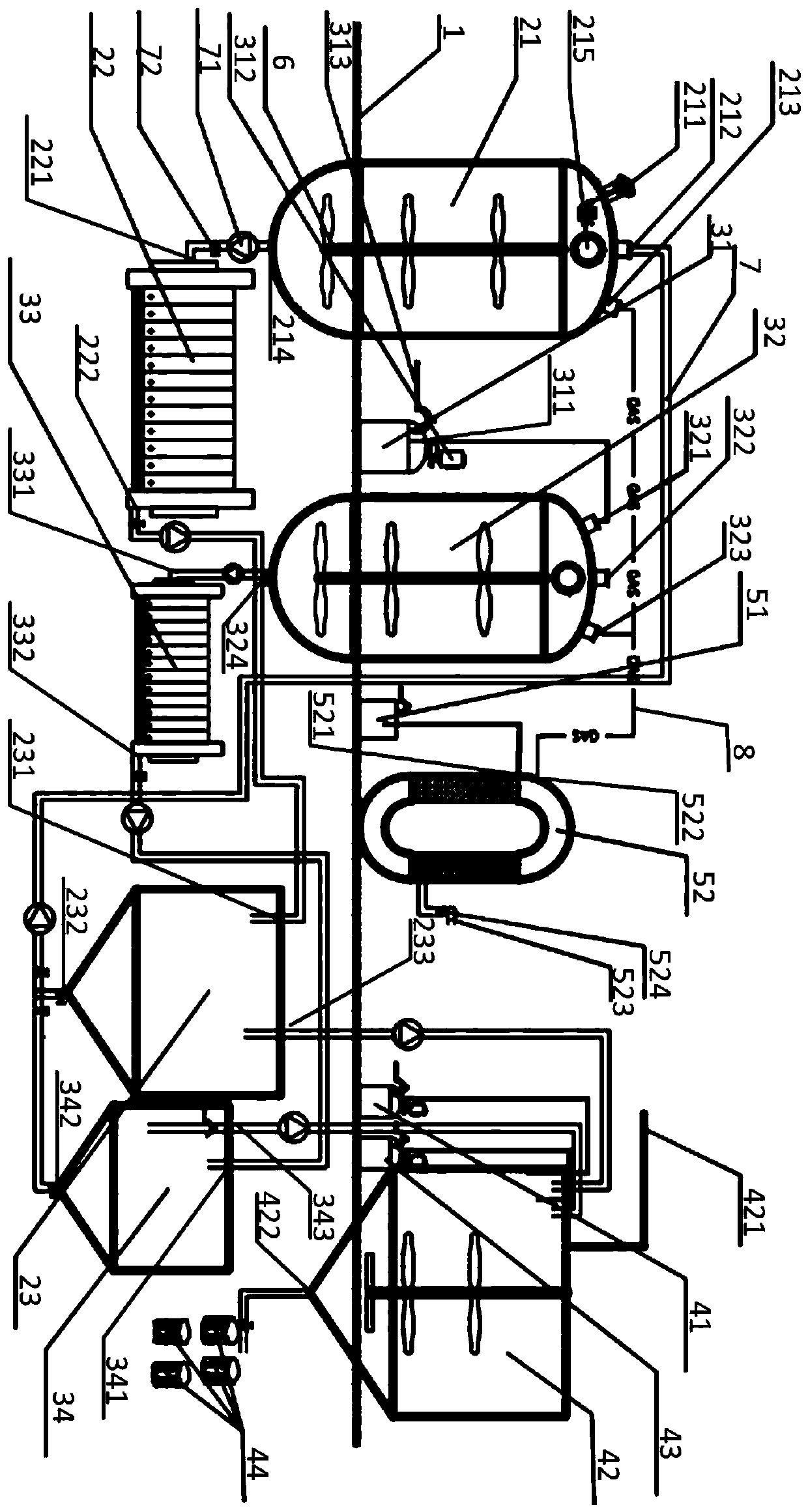

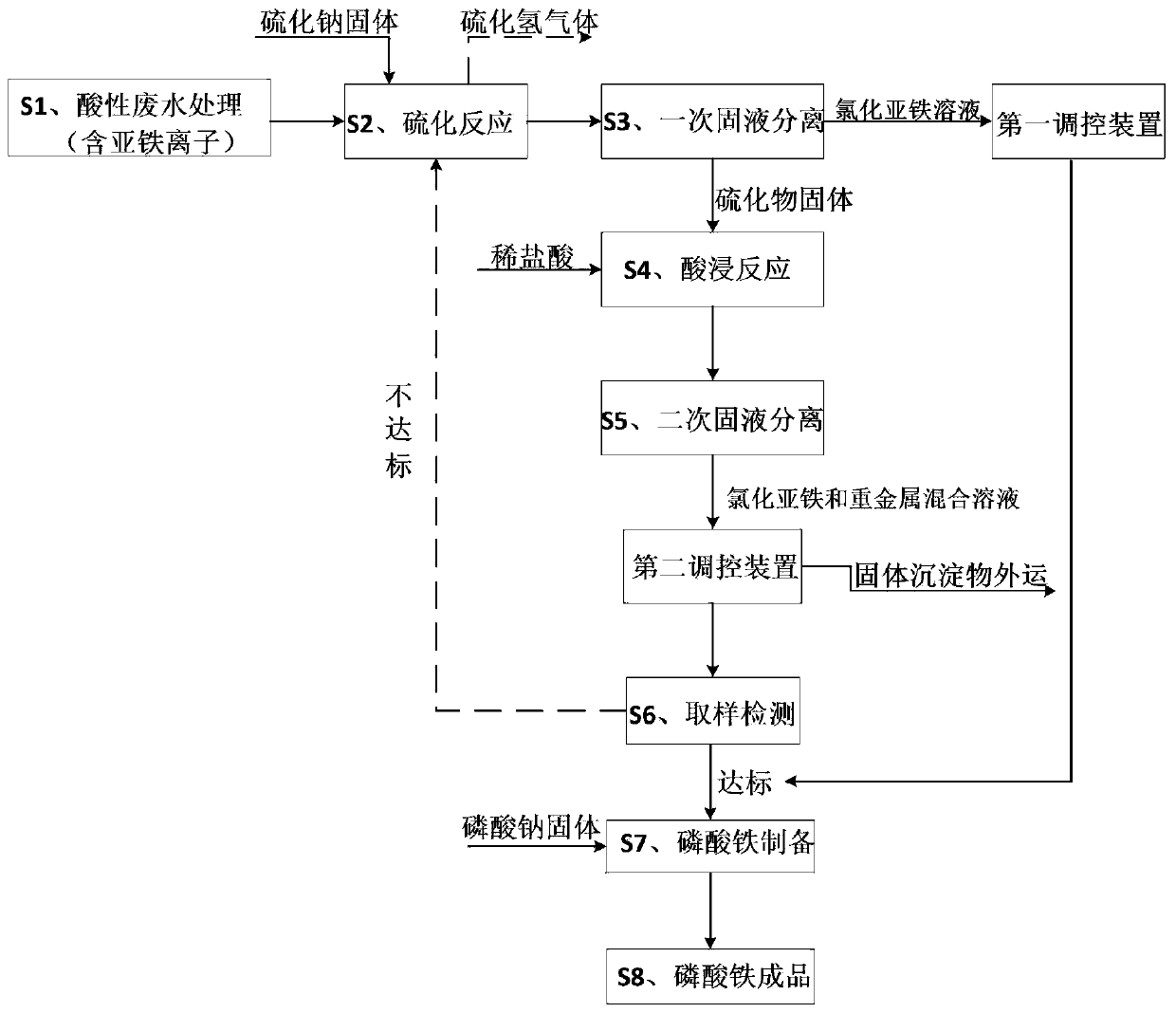

[0046] A recovery method of a resource recovery system for acid wastewater containing ferrous ions includes the following specific steps:

[0047] S1. Acidic wastewater treatment: 1t of acidic wastewater containing ferrous ions (produced by the galvanizing process) is added to the vulcanization reactor 21 through the first feeding port 212 on the vulcanization reactor 21, and stirred by the stirring blade in the vulcanization reactor 21 , Make the acidic wastewater mix uniformly; take a sample to determine the molar concentration of iron is 0.4mol / L, and the molar concentration of other heavy metal zinc is 0.1mol / L;

[0048] S2. Vulcanization reaction: Under sealed conditions, 62.43kg of sodium sulfide powder is added to the vulcanization reactor 21 through the first dosing device 211 on the vulcanization reactor. The molar ratio of heavy metals iron, zinc and sodium sulfide is 1: 2; Stirring with the stirring blade in the vulcanization reactor 21 to cause the ionic iron and zinc t...

Embodiment 2

[0057] A recovery method of a resource recovery system for acid wastewater containing ferrous ions includes the following specific steps:

[0058] S1. Acidic wastewater treatment: 1t of acidic wastewater containing ferrous ions (produced by the galvanizing process) is added to the vulcanization reactor 21 through the first feeding port 212 on the vulcanization reactor 21, and stirred by the stirring blade in the vulcanization reactor 21 , To make the acidic wastewater mixed uniformly; the molar concentration of iron is 0.4mol / L and the molar concentration of other heavy metal zinc is 0.15mol / L;

[0059] S2. Vulcanization reaction: Under sealed conditions, 128.77kg of sodium sulfide powder is added to the vulcanization reactor 21 through the first dosing device 211 on the vulcanization reactor. The molar ratio of heavy metal iron, zinc and sodium sulfide is 1:3 ; Use the stirring blade in the vulcanization reactor 21 to stir to cause the ionic iron and zinc to undergo a vulcanizatio...

Embodiment 3

[0068] A recovery method of a resource recovery system for acid wastewater containing ferrous ions includes the following specific steps:

[0069] S1. Acidic wastewater treatment: 1t of acidic wastewater containing ferrous ions (produced by the galvanizing process) is added to the vulcanization reactor 21 through the first feeding port 212 on the vulcanization reactor 21, and stirred by the stirring blade in the vulcanization reactor 21 , To make the acidic wastewater mixed uniformly; the molar concentration of iron is 0.43mol / L, and the molar concentration of other heavy metal zinc is 0.12mol / L;

[0070] S2. Vulcanization reaction: Under sealed conditions, 64.38kg of sodium sulfide powder is added to the vulcanization reactor 21 through the first dosing device 211 on the vulcanization reactor. The molar ratio of heavy metals iron, zinc and sodium sulfide is 1: 1.5; Stirring with the stirring blade in the vulcanization reactor 21 to cause the ionic iron and zinc to undergo a vulcan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com