400 MPa-grade Cr and Ti containing hot rolled ribbed steel bar and production technology thereof

A hot-rolled ribbed steel bar and production process technology, applied in the field of threaded steel bar manufacturing, can solve the problems of increasing production difficulty and spare parts consumption, failing to reach HRB400 yield strength, unable to smoothly pour steel, etc., achieving low cost and improving steel bar. The effect of strength and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

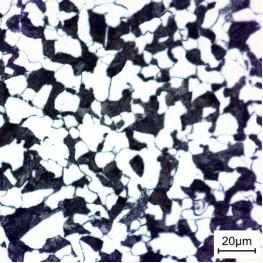

Image

Examples

Embodiment 1

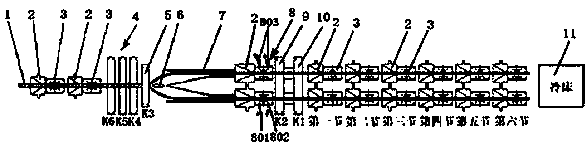

[0053] Example 1: A 400MPa grade Cr and Ti hot-rolled ribbed steel bar is smelted by converter → tapping → argon blowing → ferrotitanium addition → continuous casting → heating → initial rolling → intermediate rolling → water precooling → finish rolling →Water cooling between the finishing stands→The finished product is water cooled for the first time→The finished product is made by water cooling for the second time. The rolling target diameter is Φ20mm, including the following process steps:

[0054] (1) Converter smelting, argon blowing, continuous casting: Add molten iron and steel scrap into a 100-ton converter, top-bottom double blowing smelting, oxygen blowing to remove C, blowing argon for 140s (seconds) during the steel discharge process, argon blowing pressure 0.80MPa, press System slag wash. Add silicomanganese, ferrosilicon, carbon silicon balls, high carbon ferrochrome in order when tapping 1 / 4 of the steel, deoxidize and alloy, transfer the ladle to the argon blow...

Embodiment 2

[0064] Example 2: A 400MPa grade Cr and Ti hot-rolled ribbed steel bar is smelted by converter → tapping → argon blowing → ferrotitanium addition → continuous casting → heating → initial rolling → intermediate rolling → water precooling → finish rolling →Water cooling between the finishing stands→The finished product is water cooled for the first time→The finished product is made by water cooling for the second time. The rolling target diameter is Φ22mm, including the following process steps:

[0065] (1) Converter smelting, argon blowing, continuous casting: Add molten iron and steel scrap into a 100-ton converter, top-bottom double-blowing smelting, oxygen blowing to remove C, blowing argon for 145s (seconds) during the steel discharge process, argon blowing pressure 0.80MPa, press System slag wash. Add silicomanganese, ferrosilicon, carbon silicon balls, high carbon ferrochrome in order when tapping 1 / 4 of the steel, deoxidize and alloy, transfer the ladle to the argon blow...

Embodiment 3

[0074] Example 3: A 400MPa grade Cr and Ti hot-rolled ribbed steel bar is smelted by converter → tapping → argon blowing → ferrotitanium addition → continuous casting → heating → initial rolling → intermediate rolling → water precooling → finish rolling →Water cooling between the finishing stands→The finished product is water cooled for the first time→The finished product is made by water cooling for the second time. The rolling target diameter is Φ25mm, including the following process steps:

[0075] (1) Converter smelting, argon blowing, continuous casting: Add molten iron and steel scrap into a 100-ton converter, top-bottom double-blowing smelting, oxygen blowing to remove C, blowing argon for 150s (seconds) during the steel discharge process, argon blowing pressure 0.75MPa, press System slag wash. Add silicomanganese, ferrosilicon, carbon silicon balls, high carbon ferrochrome in order when tapping 1 / 4 of the steel, deoxidize and alloy, transfer the ladle to the argon blow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com