A preparation method of aramid nanofiber self-reinforced aramid mica paper

A nanofiber, aramid fiber technology, applied in synthetic cellulose/non-cellulose material pulp/paper, fiber raw material processing, papermaking, etc., can solve the limited improvement of mechanical strength and dielectric strength, and the low retention rate of mica and other problems, to achieve the effect of improving the dielectric strength and mechanical strength, improving the retention rate of mica, and improving the mechanical strength of paper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

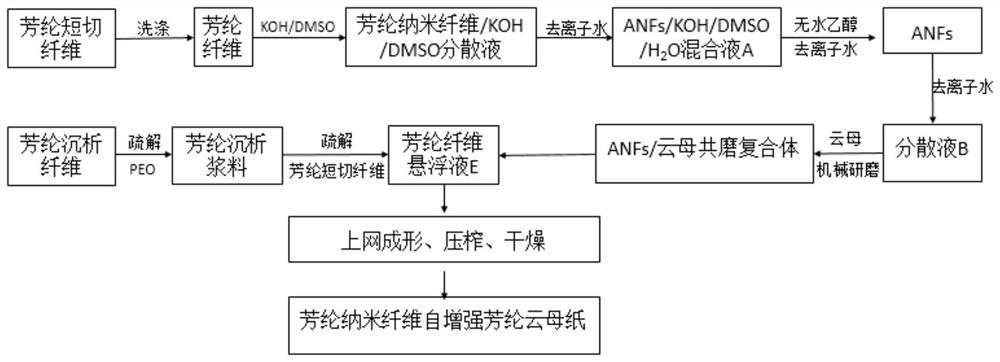

[0029] (1) Preparation of aramid nanofiber suspension. The para-aramid chopped fibers are washed with sodium dodecylbenzenesulfonate (LAS) hot water to obtain aramid fibers; the aramid fibers, potassium hydroxide, and dimethyl sulfoxide are placed in a container at the same time , continuous mechanical stirring after sealing, to obtain the aramid nanofiber dispersion A stably dispersed in the KOH / DMSO system;

[0030] Among them, the concentration of LAS is 1.2~1.5×10 -3 mol / L, hot water washing conditions are: temperature 60-80°C, mechanical stirring time 30-60min, ratio of para-aramid chopped fiber, potassium hydroxide, dimethyl sulfoxide is 1g:1.5g:500ml, continuous The specific requirements for mechanical stirring are: under sealed conditions, use a magnetic stirrer to stir at room temperature for 5 to 7 days, with a rotation speed of 550 to 850 rpm.

[0031] (2) Under continuous mechanical stirring, slowly inject deionized water into the above dispersion to obtain arami...

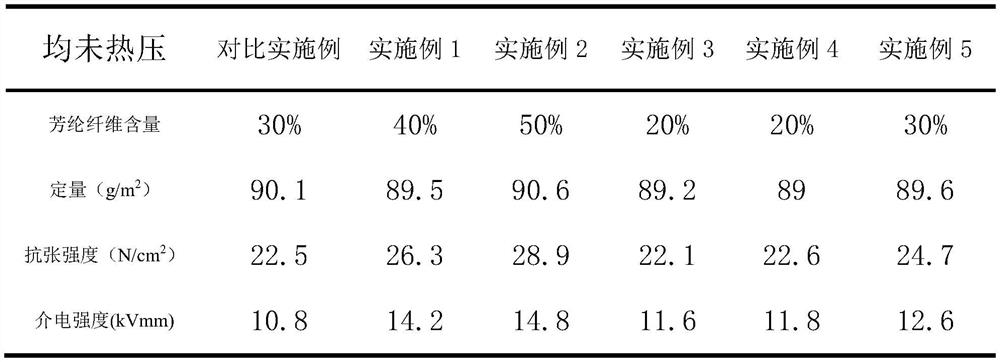

Embodiment 1

[0048] A method for preparing aramid nanofiber self-reinforced aramid mica paper in this embodiment, the specific preparation steps are as follows:

[0049] (1) Preparation of aramid nanofiber suspension. The p-aramid chopped fibers were treated with sodium dodecylbenzenesulfonate (LAS) at a concentration of 1.2×10 -3 mol / L hot water washing treatment at 60°C to obtain aramid fiber; put the aramid fiber, potassium hydroxide, and dimethyl sulfoxide in a container at the same time in a ratio of 1g: 1.5g: 500ml, seal and continue mechanical stirring , stirring at room temperature at 550 rpm for 7 days to obtain the aramid nanofiber dispersion A stably dispersed in the KOH / DMSO system;

[0050] (2) Under continuous mechanical stirring, slowly inject deionized water into the above-mentioned dispersion liquid, the mass ratio of deionized water and aramid fiber nanofiber dispersion liquid is 2:1, obtain the aramid fiber nanofiber dispersed in the aqueous phase system / KOH / DMSO / H 2...

Embodiment 2

[0058] A method for preparing aramid nanofiber self-reinforced aramid mica paper in this embodiment, the specific preparation steps are as follows:

[0059] (1) Preparation of aramid nanofiber suspension. The p-aramid chopped fibers were treated with sodium dodecylbenzenesulfonate (LAS) at a concentration of 1.5×10 -3 mol / L hot water washing treatment at 80°C to obtain aramid fiber; put the aramid fiber, potassium hydroxide, and dimethyl sulfoxide in a container at the same time in a ratio of 1g: 1.5g: 500ml, seal and continue mechanical stirring , stirring at room temperature at 850 rpm for 5.5 days to obtain the aramid nanofiber dispersion A stably dispersed in the KOH / DMSO system;

[0060] (2) Under continuous mechanical stirring, slowly inject deionized water into the above-mentioned dispersion liquid, the mass ratio of deionized water and aramid fiber nanofiber dispersion liquid is 5:1, and obtain the aramid fiber nanofiber dispersed in the aqueous phase system / KOH / DMS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com