Method for rapid preparation of metallographic standard samples of high carbon steel

A standard sample, high carbon steel technology, applied in the field of heat treatment, can solve the problems of polluting the environment, harmful to the health of operators, increasing the cost of alloys, etc., to achieve the effect of simple operation process and no pollution cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The chemical composition of high carbon steel includes C: 0.794%, Si: 0.21%, Mn: 0.31%, S: 0.010%, P: 0.025%, and the rest is Fe;

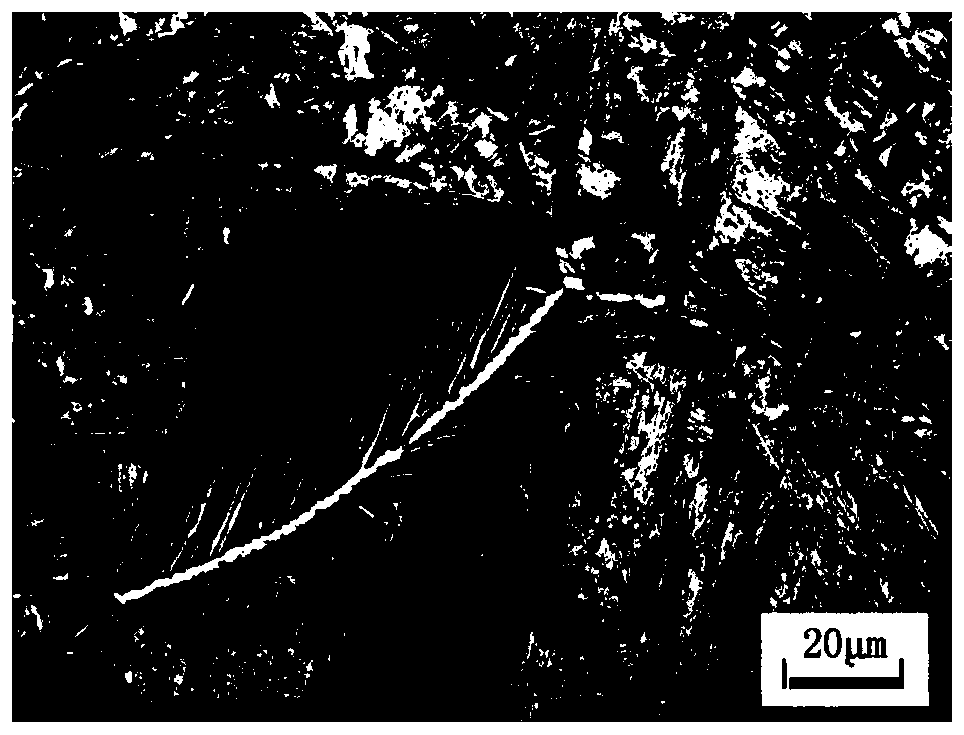

[0025] High carbon steel is smelted by medium frequency induction furnace, annealed after forging, processed into The size of the sample; will The high-carbon steel sample was placed in the vacuum chamber of the thermal simulation testing machine, and the sample was heated to 800°C and held for 10 minutes to make it fully austenitized; the austenitized sample was heated at 410°C / s Rapid cooling to 380°C, holding time 120s, then cooling to room temperature at a faster cooling rate of 50°C / s, corroding the sample with 3% nitric acid alcohol solution and analyzing the metallographic structure of the sample to obtain a metallographic standard sample ,Such as figure 1 The obtained structure is upper bainite + martensite + retained austenite.

Embodiment 2

[0027] The chemical composition of high carbon steel includes C: 0.84%, Si: 0.25%, Mn: 0.35%, S: 0.009%, P: 0.011%, and the rest is Fe;

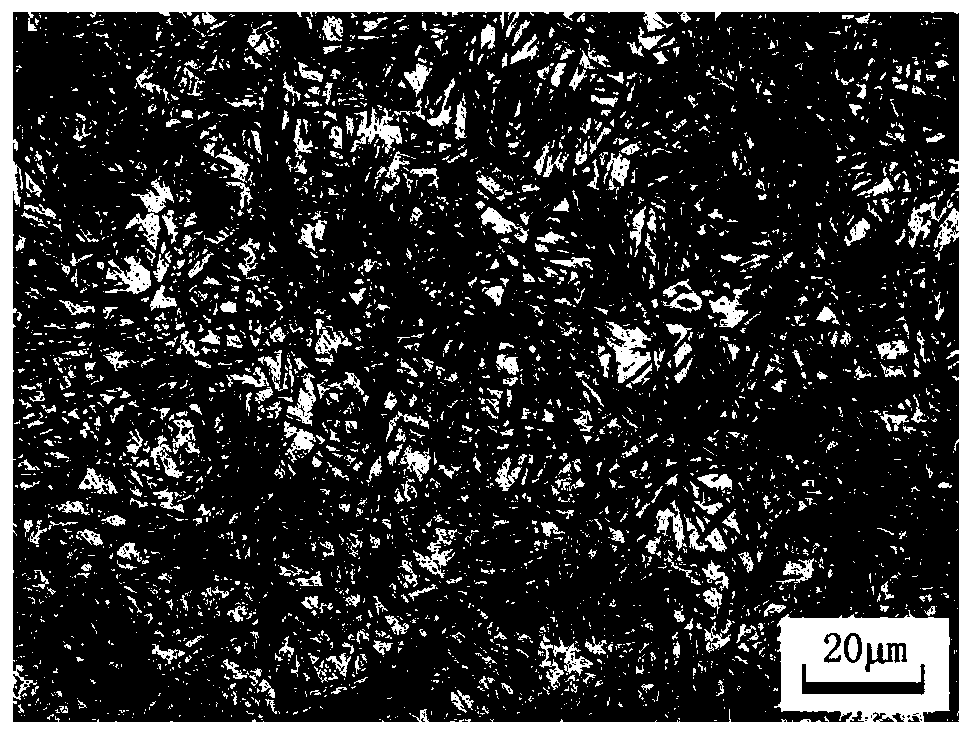

[0028] High carbon steel is smelted by medium frequency induction furnace, annealed after forging, processed into The size of the sample; will The high-carbon steel sample is placed in the vacuum chamber of the thermal simulation testing machine, and the sample is heated to 780°C and kept for 15 minutes to make it fully austenitized; the austenitized sample is heated at 420°C / s Rapid cooling to 280°C, holding time 240s, then cooling to room temperature at a faster cooling rate of 40°C / s, corroding the sample with 4% nitric acid alcohol solution and analyzing the metallographic structure of the sample to obtain a metallographic standard sample ,Such as figure 2 The obtained structure is lower bainite + martensite + retained austenite.

Embodiment 3

[0030] The chemical composition of high carbon steel includes C: 0.82%, Si: 0.31%, Mn: 0.39%, S: 0.012%, P: 0.016%, and the rest is Fe;

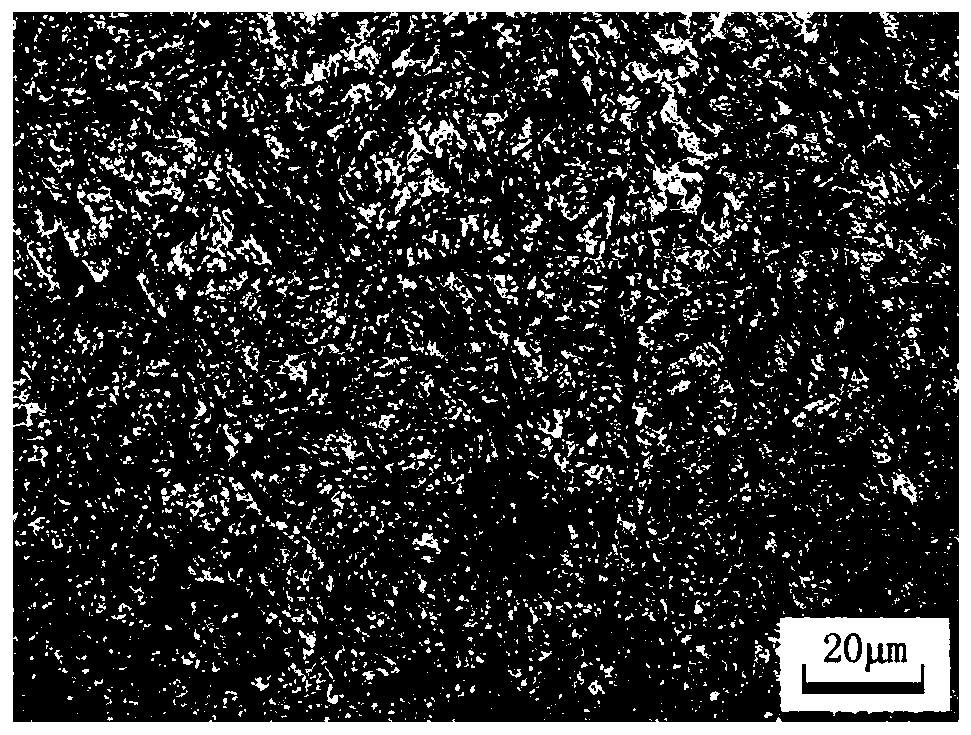

[0031] High carbon steel is smelted by medium frequency induction furnace, annealed after forging, processed into The size of the sample; will The high-carbon steel sample is placed in the vacuum chamber of the thermal simulation testing machine, and the sample is heated to 790°C and kept for 13 minutes to make it fully austenitized; the austenitized sample is heated at 430°C / s Rapid cooling to 190°C, holding time 180s, then cooling to room temperature at a faster cooling rate of 45°C / s, corroding the sample with 5% nitric acid alcohol solution and analyzing the metallographic structure of the sample to obtain a metallographic standard sample ,Such as image 3 The obtained structure is martensite + retained austenite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com