Photodegradable light-sensitive molecular sulfide ore inhibitor as well as preparation method and application thereof

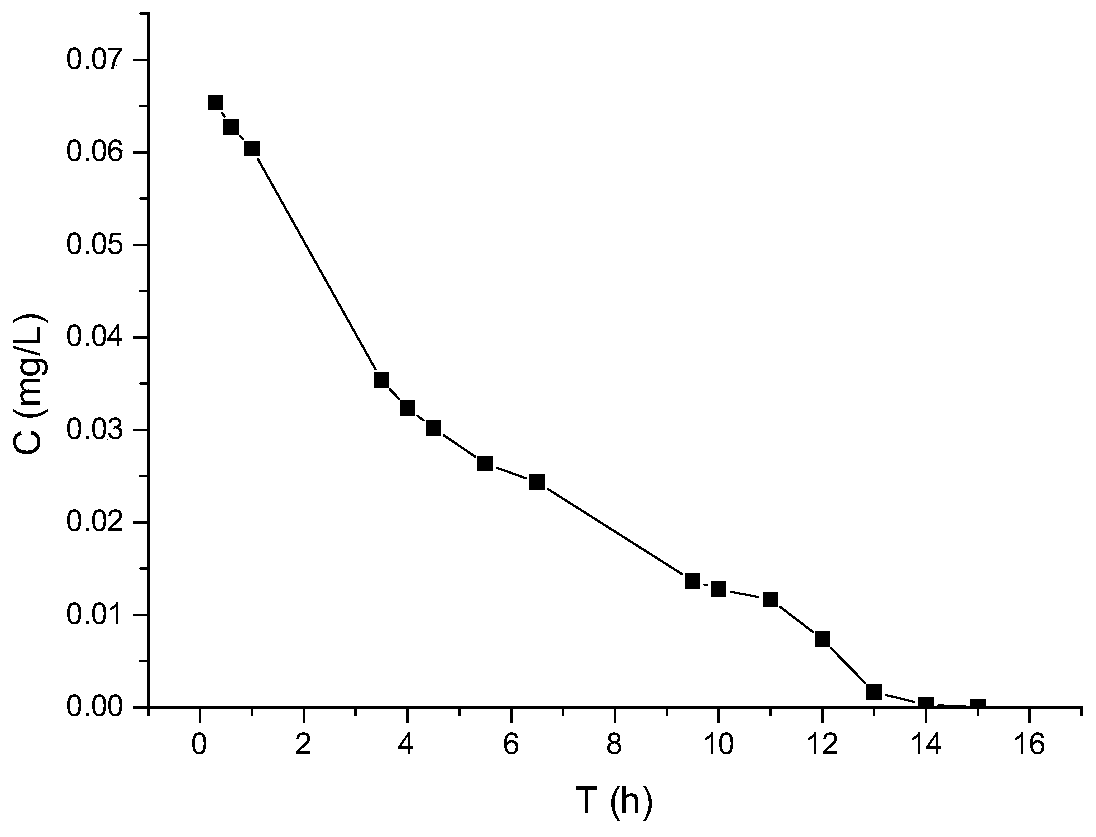

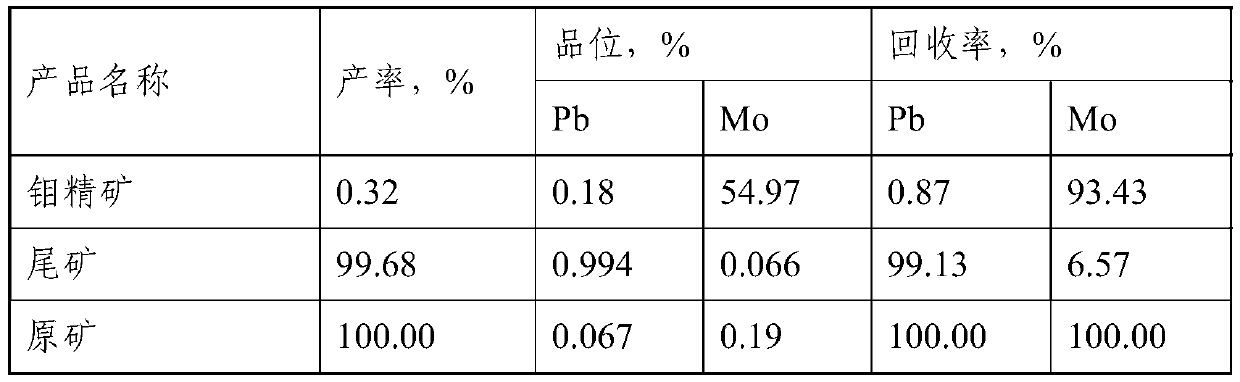

A technology of small molecule inhibitor and photodegrader, applied in solid separation, flotation and other directions, can solve problems such as environmental pollution, and achieve the effects of low cost, good photodegradation performance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]In a 500ml three-neck flask, add 200g of water and 53g of sodium hydroxide in turn, stir to dissolve, continue to stir until the temperature is below 35°C, add 104g of gallic acid, and stir for 30min until dissolved. Raise the temperature of the above reaction solution to 40°C, add 49g of carbon disulfide, control the reaction temperature at 45-50°C, and continue the reaction for 5 hours; Agent diethyl dithiocarbamate ferric, stirred for 1 hour to obtain an orange-red aqueous solution, which is a photodegradable photosensitive molecular sulfide mineral inhibitor.

Embodiment 2

[0046] In a 500ml three-neck flask, add 180g of water and 71g of sodium hydroxide in sequence, stir to dissolve, continue to stir until the temperature is below 35°C, add 78g of citric acid, and stir for 40min until dissolved. Raise the temperature of the above reaction solution to 45°C, add 35g of carbon disulfide, control the reaction temperature at 45-55°C, and continue the reaction for 4 hours; Add 3.5g of photodegradant ferric dibutyldithiocarbamate, stir for 2h, let stand for 12h, filter to remove trace precipitate at the bottom, take the supernatant to obtain an orange-red aqueous solution, which is the photodegradable photosensitive molecular sulfide inhibitor.

Embodiment 3

[0048] In a 500ml three-necked flask, add 168g of water and 122g of polyacrylamide in turn, stir to dissolve, gradually add 9.5g of NaOH, continue stirring to keep the temperature below 30°C. After fully dissolving, 20g of carbon disulfide was added dropwise, and the temperature was raised step by step. Raise the temperature to 35°C, keep it for 1h, continue to raise the temperature to 45°C, keep it for 2h, and finally raise the temperature to 65°C, and keep it for 1h. After the reaction solution is placed and cooled to below 30°C, it will be a sulfide mineral inhibitor; then add 10.5g of photodegradant ferric dibutyl dithiocarbamate to it, stir for 3 hours, let it stand for 12 hours, and filter to remove the trace precipitate at the bottom. The supernatant was taken to obtain an orange-yellow aqueous solution, which was the photodegradable photosensitive molecular sulfide inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com