Series alumina production process

A production process and method of alumina technology, which is applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, inorganic chemistry, aluminum compounds, etc., and can solve the problem of narrow sintering temperature range, strict equipment requirements, and low added value of products and other problems, to achieve the effect of high dissolution rate, lower overall cost, lower infrastructure investment and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

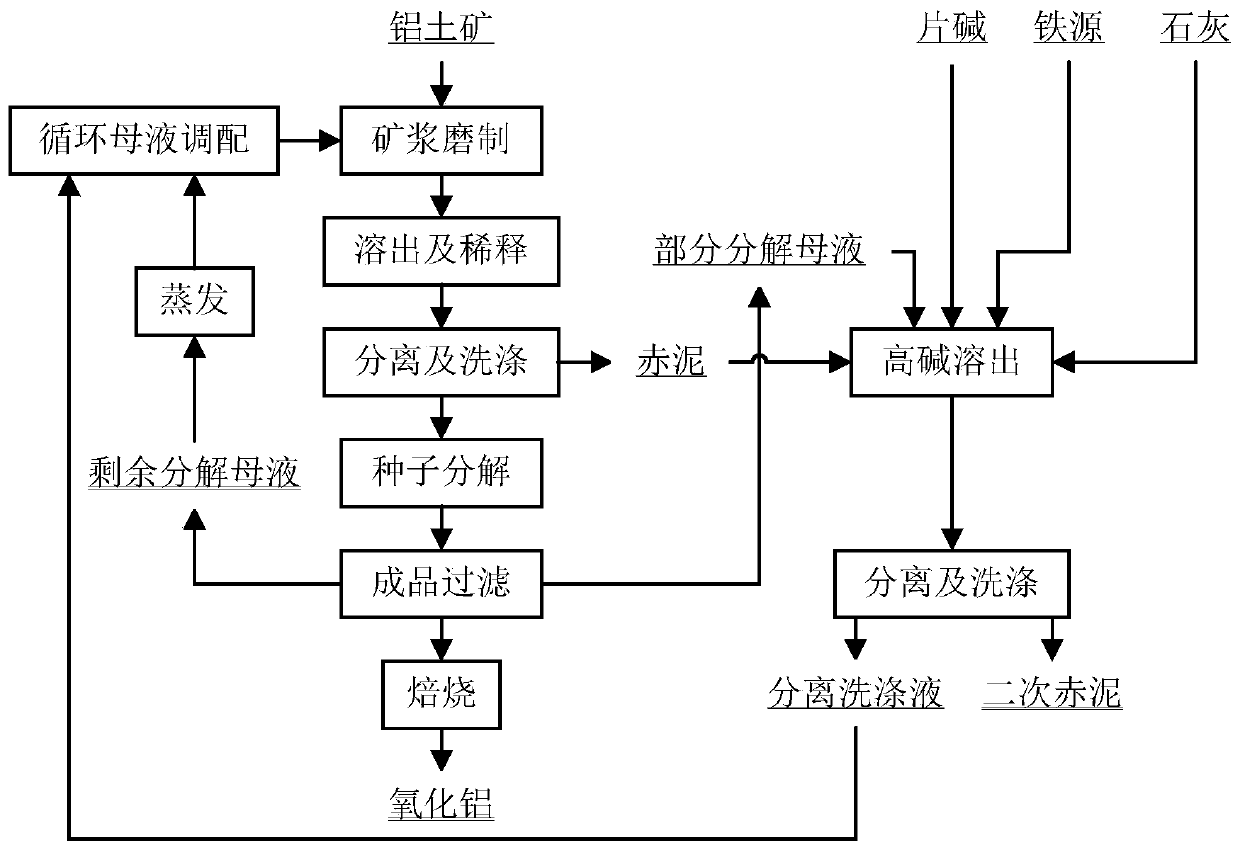

[0034] Such as figure 1 As shown, the present embodiment tandem alumina production process is carried out according to the following steps:

[0035] (1) Mix part of the mother liquor decomposed by the Bayer process with red mud evenly, and add fine iron ore, caustic soda and lime to make a slurry to be dissolved. The amount of decomposed mother liquor is based on the mass ratio of liquid to solid in the slurry to be dissolved is 3.5, and the amount of iron ore added is based on the amount of Fe in the iron ore. 2 o 3 Al in red mud 2 o 3 The mol ratio is 0.4; the addition of caustic soda is 20 according to αk in the slurry to be dissolved, and the Nk is 260g / l; the addition of lime is based on the 0.5 ton of active lime added per ton of dry red mud, and the slurry to be dissolved is Reaction at 230°C for 1.0h.

[0036] (2) The material after dissolution is separated from solid and liquid to obtain secondary red mud and dissolution separation liquid; the secondary red mud i...

Embodiment 2

[0040] Such as figure 1 As shown, the present embodiment tandem alumina production process is carried out according to the following steps:

[0041] (1) Mix part of the mother liquor decomposed by the Bayer process with high-iron red mud evenly, and add caustic soda and lime to make a slurry to be dissolved. The amount of decomposed mother liquor is calculated according to the mass ratio of liquid to solid in the slurry to be dissolved is 4.0; the amount of caustic soda is calculated according to the αk in the slurry to be dissolved is 25, and the Nk is 280g / l; the amount of lime added is calculated as per ton of dry red mud 0.4 tons of active lime; react the slurry to be dissolved at 245°C for 0.5h.

[0042] (2) The material after dissolution is separated from solid and liquid to obtain secondary red mud and dissolution separation liquid; the secondary red mud is washed with hot water at 95°C to obtain by-product secondary red mud filter cake and secondary red mud washing li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com