Biofilm magnetic field device and method for treating sewage by photosynthetic organisms

A technology of photosynthetic organisms and biofilms, applied in the direction of biological water/sewage treatment, water/sewage treatment, water treatment parameter control, etc., can solve problems such as inability to improve photosynthetic bacteria membrane bioreactor sewage treatment effect and biomass production , to shorten the hydraulic retention time and improve the efficiency of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

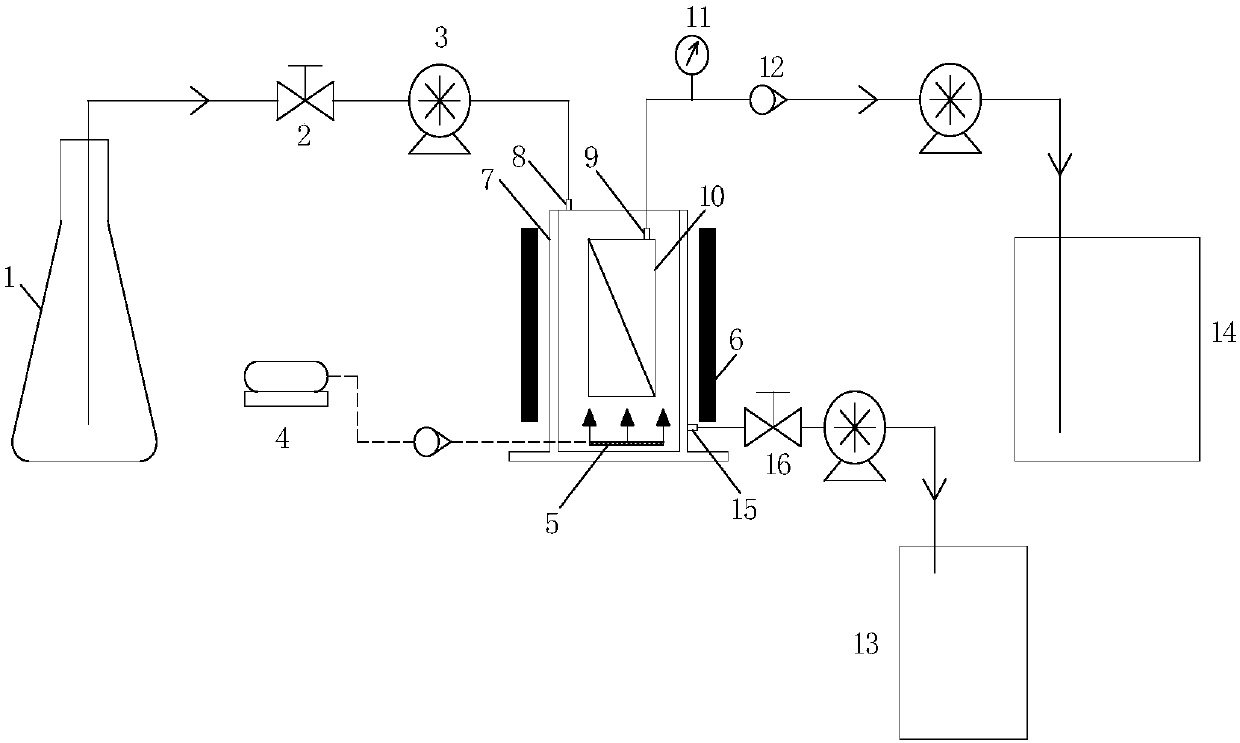

[0042] Such as figure 1 , a photosynthetic bacteria membrane bioreactor wastewater treatment device based on magnetic field radiation, comprising a membrane bioreactor 7, a magnet 6,

[0043] A flat membrane 10 is placed in the membrane bioreactor, and two magnets are placed on both sides of the membrane bioreactor in the width direction of the flat membrane, so that the direction of the magnetic force lines is parallel to the width direction of the flat membrane. The membrane bioreactor 7 is provided with a water inlet 8 and a water outlet 9, and the water inlet 8 is connected with a waste water storage tank 1 through a waste water inlet pipe; the water outlet 9 is connected with an outlet water storage tank 14 through a water outlet pipe;

[0044] An aeration head 5 is arranged at the bottom of the membrane bioreactor, and the aeration head is connected to an air compression pump 4 through a compressed air pipeline. A glass rotameter is installed on the compressed air pipel...

Embodiment 2

[0059] In this embodiment, the COD concentration in the treated food processing wastewater is 3100 mg / L, and the SS concentration is 41.3 mg / L. Adopt the equipment identical with embodiment 1, comprehensive processing step:

[0060] 1. Test the pH in the wastewater storage tank and adjust it to 6.8;

[0061] 2. Through the water pump, pump 1L of regulated food processing wastewater from the wastewater storage tank to the photosynthetic bacteria membrane bioreactor, add 1L of photosynthetic bacteria mixture that has reached the plateau, and the final concentration of photosynthetic bacteria is 3200mg / L dry weight, The total liquid volume is three-fifths of the volume of the reactor main body;

[0062] 3. Turn on the air compressor pump, adjust the gas flow meter, and aerate the reactor so that the oxidation-reduction potential (ORP) is -100-20mV;

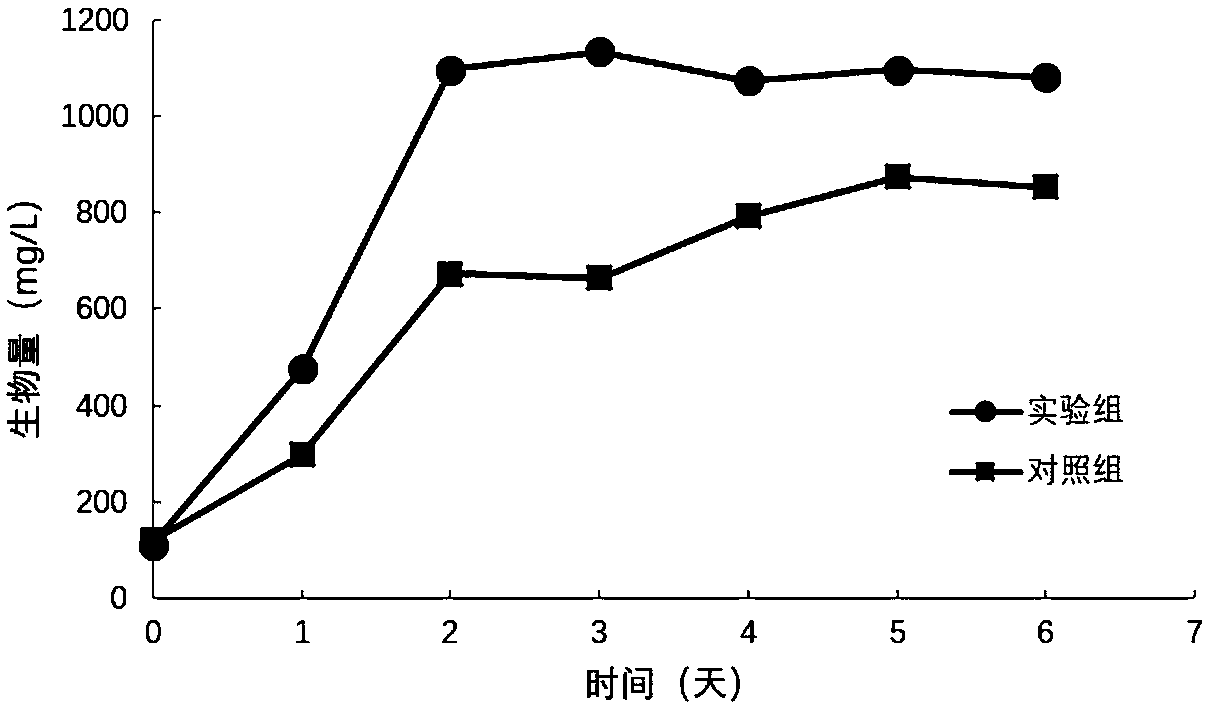

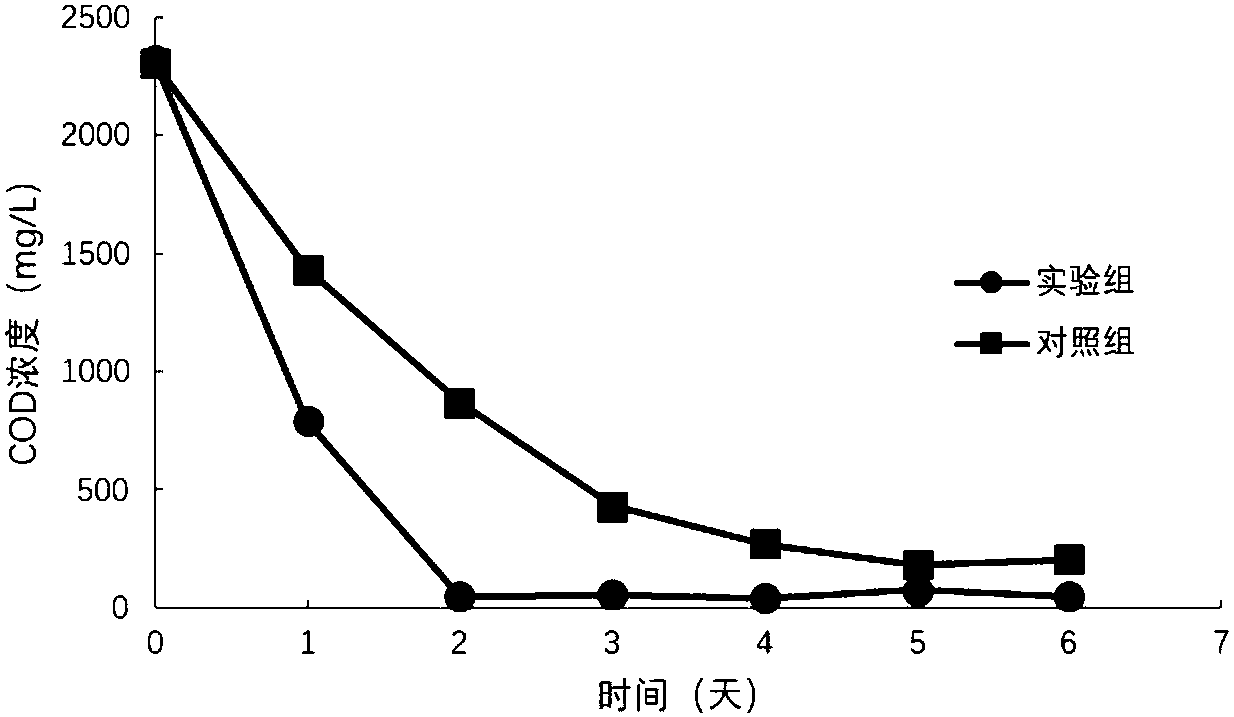

[0063] 4. In the experimental group, a magnet with a magnetic field strength of 0.8 T was selected and fixed on both sides of the...

Embodiment 3

[0068] In this embodiment, the COD concentration in the treated food processing wastewater is 2700 mg / L, and the SS concentration is 31.7 mg / L. Adopt the equipment identical with embodiment 1, comprehensive processing step:

[0069] Comprehensive processing steps:

[0070] 1. Test the pH in the wastewater storage tank and adjust it to 6.8;

[0071] 2. Through the water pump, pump 1.9L of adjusted food processing wastewater from the wastewater storage tank to the photosynthetic bacteria membrane bioreactor, add 0.1L of the photosynthetic bacteria mixture that has reached the plateau, and the final concentration of photosynthetic bacteria is 100mg / L. Heavy, the total liquid volume is three-fifths of the volume of the reactor main body;

[0072] 3. Turn on the air compressor pump, adjust the gas flow meter, and aerate the reactor so that the oxidation-reduction potential (ORP) is -100-20mV;

[0073] 4. Select a magnet with a magnetic field strength of 0.04T and fix it on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com