Environmental protection insole preparation process based on water hyacinth raw material

A preparation process and technology of water hyacinth, which is applied to insoles, sanitary equipment for toilets, footwear, etc., can solve the problems of water hyacinth spreading disasters, creatures not getting enough light, blocking sunlight, etc., and improving economic benefits and social benefits, improve the sterilization effect, and promote the effect of environmental governance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

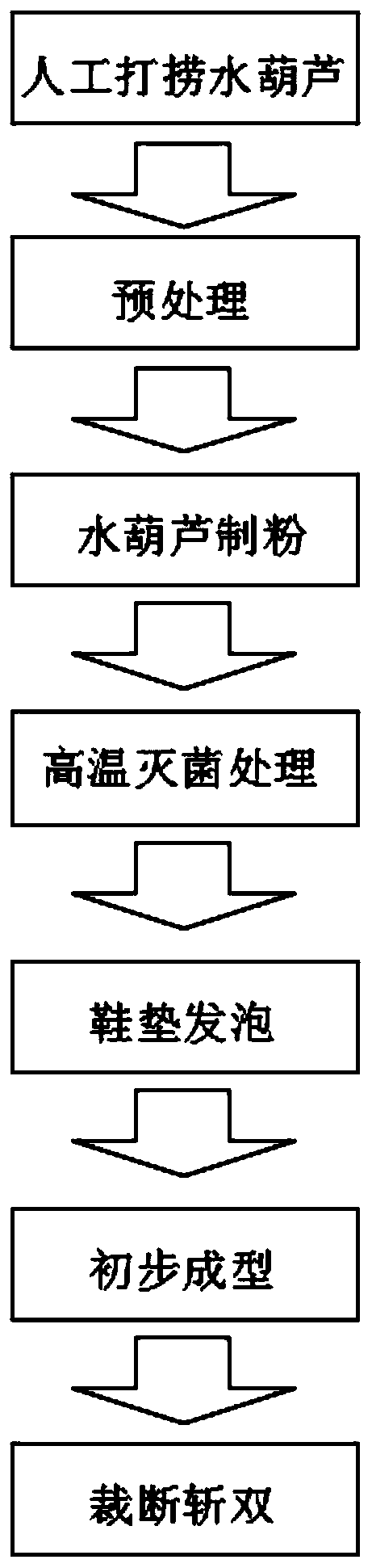

[0047] see figure 1 , a kind of environmental protection insole preparation technology based on water hyacinth raw material, comprises the following steps:

[0048] S1. Manually pick up the fresh water hyacinth, clean the excess attachments, and then spread and dry them naturally;

[0049] S2. Pretreatment, drying and sterilizing the dried water hyacinth under a vacuum condition of 100° C.;

[0050] In the pretreatment, dry the water hyacinth at high temperature until the dehydration rate reaches 90%. If the dehydration rate is lower than 90%, continue to dry at high temperature to increase the dehydration rate to reduce the impact of the moisture contained in the water hyacinth on the subsequent process.

[0051] S3, water hyacinth powder making, the dried water hyacinth is evenly pulverized by a pulverizer to obtain water hyacinth powder, and the pulverized water hyacinth powder has a particle size of 40-60 mesh;

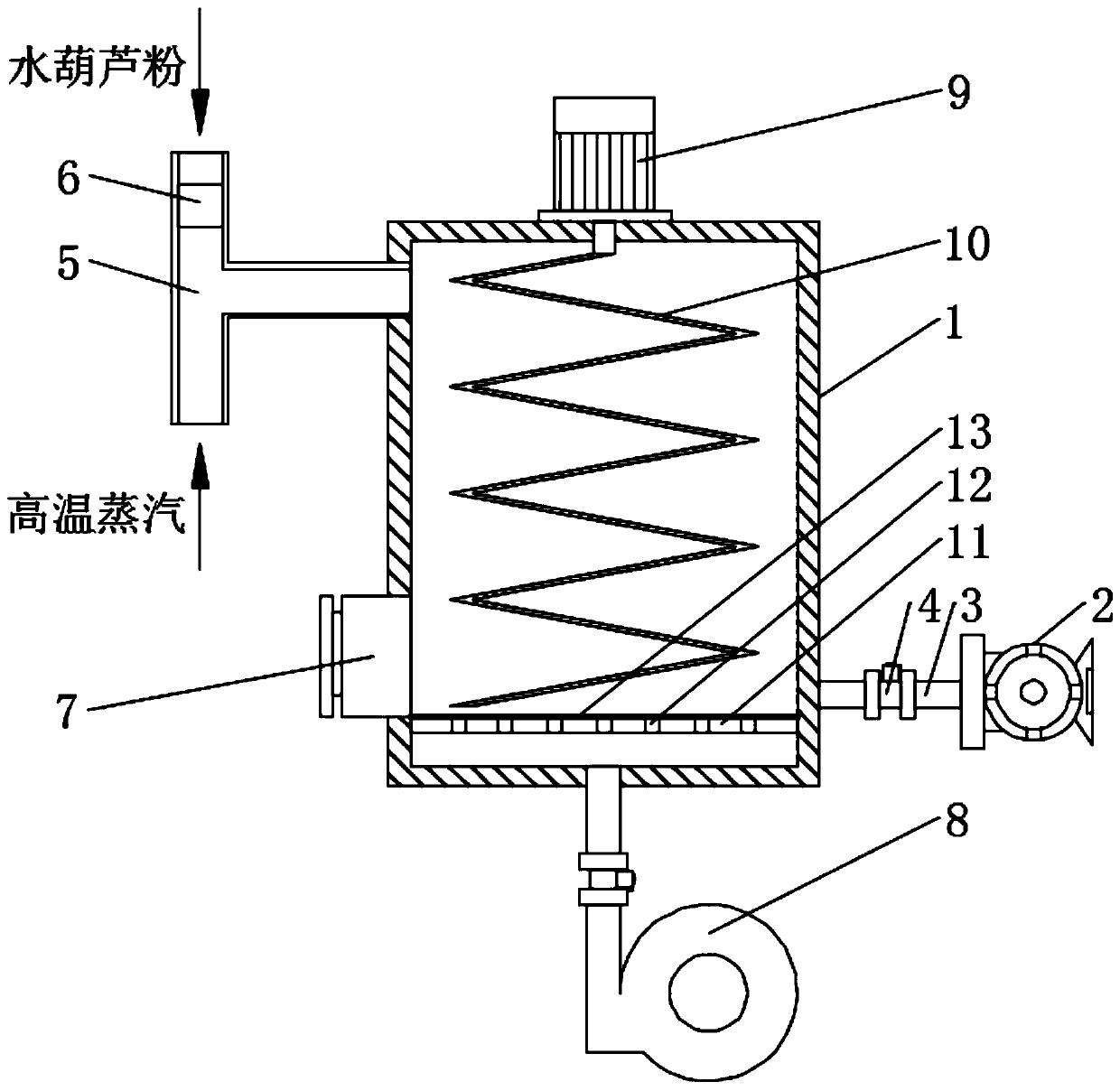

[0052] S4, high-temperature sterilization treatment, the w...

Embodiment 2

[0064] The foaming material for insole foaming is 40% polyethylene, 20% talcum powder, 1% crosslinking agent, 0.5% crosslinking auxiliary agent, 4% foaming agent, 4% foaming auxiliary agent, 1% lubricant, graphite Alkene 5%, silicon dioxide 8%, and the content ratio of water hyacinth powder and foaming material is 1:3, and the rest are consistent with embodiment 1.

Embodiment 3

[0066] The foaming material of described insole foaming is polyethylene 60%, talcum powder 25%, crosslinking agent 2%, crosslinking auxiliary agent 1%, foaming agent 10%, foaming auxiliary agent 5%, lubricant 2% , graphene 15%, silicon dioxide 15%, and the content ratio of water hyacinth powder and foaming material is 1:2, all the other are consistent with embodiment 1.

[0067] The present invention can use fresh water hyacinth salvaged manually as a raw material, and after washing and drying at high temperature, dehydration at high temperature, crushing into powder and high temperature sterilization, water hyacinth powder can be obtained. The advantages and functions brought by water hyacinth, at the same time, through strict high-temperature sterilization treatment to avoid harm to the human body, and it is mixed with foaming raw materials and then foamed to make a large plate, giving full play to its environmental protection, pollution-free, deodorization The advantages of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com