Quantum dot electroluminescent device and preparation method thereof

A technology for electroluminescent devices and quantum dots to emit light, which is applied in the fields of electro-solid devices, semiconductor/solid-state device manufacturing, and electrical components. The effect of improving and reducing exciton quenching and improving device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

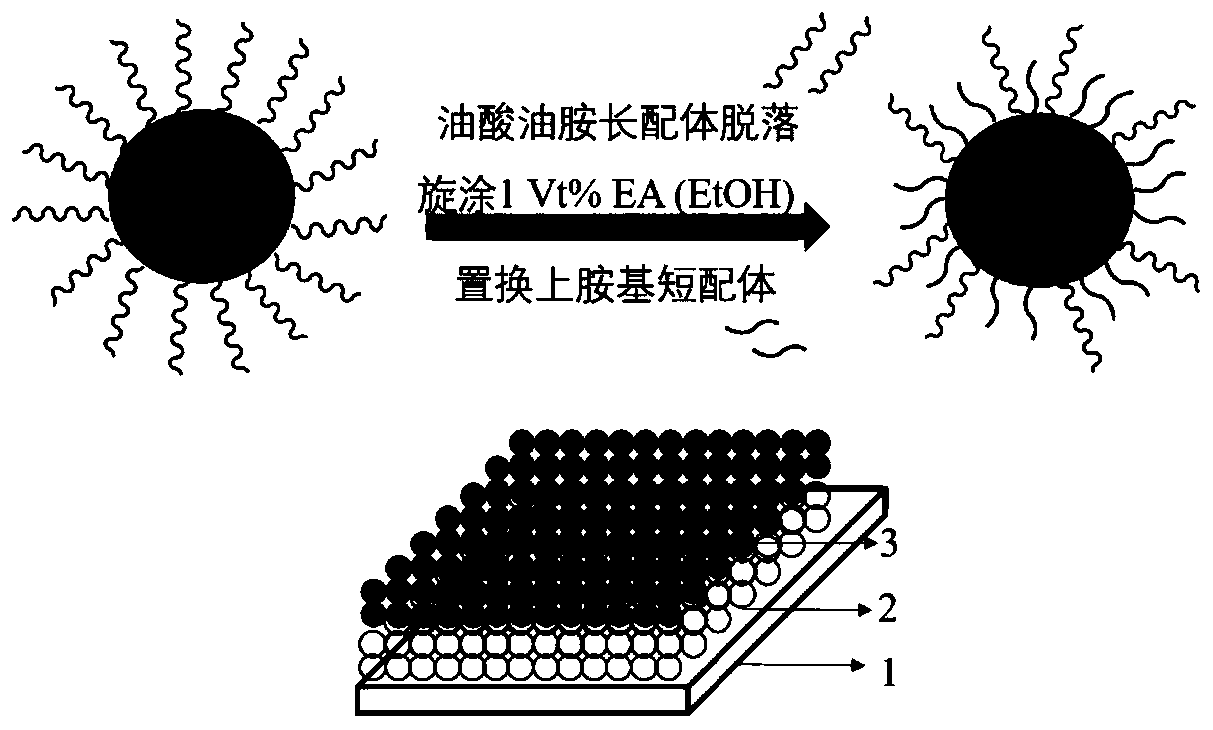

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, the quantum dots are red light quantum dots, and the preparation process of the quantum dot electroluminescent device is as follows:

[0032] 1. Cleaning and drying of ITO substrate

[0033] The size of ITO glass cube is 15mm×15mm. The following steps are used to clean ITO glass: acetone → isopropanol → special detergent for micron-sized semiconductors (a mixed solution of special detergent for micron-sized semiconductors and deionized water with a volume ratio of 1:100) → twice deionized water → new Ultrasonic cleaning with isopropanol for 10 minutes each, and drying in a constant temperature oven for two hours for later use. Electron transport layer preparation

[0034] Spin-coat ZnO on ITO glass as an electron transport layer with a homogenizer at a speed of 3000 rpm, then heat-treat it in a glove box at 180°C for 12min, and the thickness is 60nm after cooling.

[0035] 2. Preparation of quantum dot luminescent layer

[0036] The red light CdS...

Embodiment 2

[0053] In this embodiment, a method for improving the performance of quantum dot light-emitting diode devices by replacing quantum dot ligands with ligands in situ, other parameters are the same as those in Embodiment 1. The difference is that the implemented quantum dots are green light CdS / ZnS quantum dots.

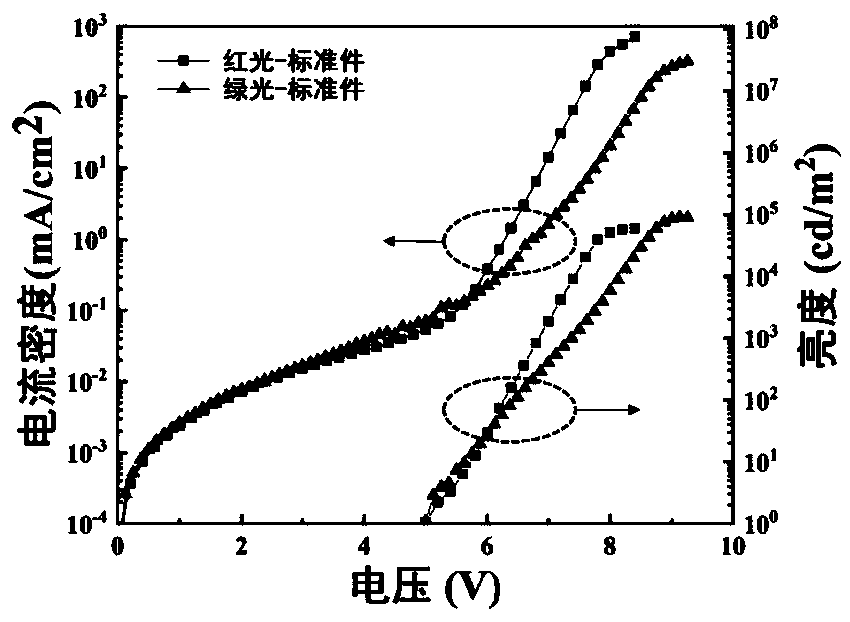

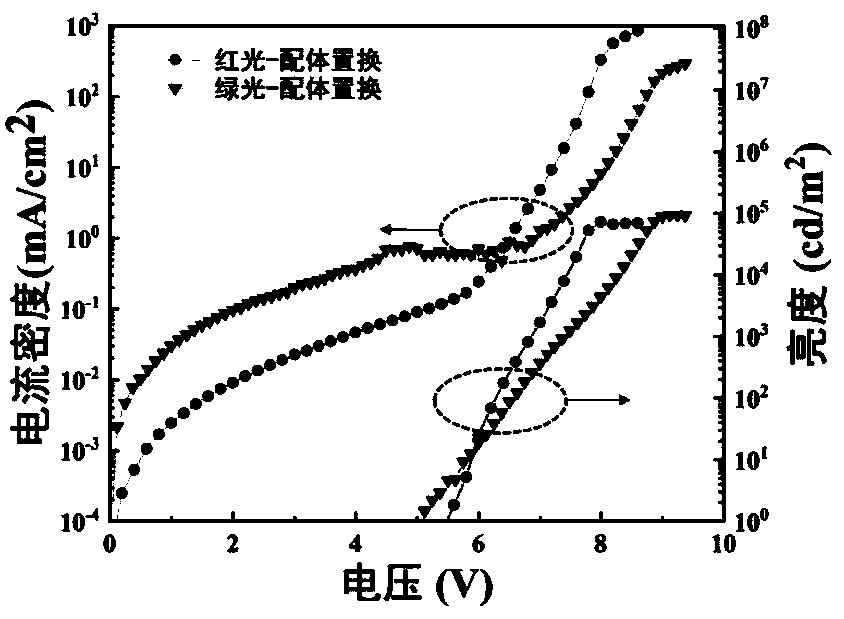

[0054] The current density-voltage-brightness curve of the quantum dot light-emitting device of this embodiment is as follows Figure 2a-2b as shown, Figure 2a And the green light standard in Figure 3-6 refers to the quantum dot light-emitting device obtained without in-situ ligand replacement, other preparation conditions are the same as in Example 2, and the maximum brightness of the green light quantum dot light-emitting standard is 8.9×10 3 , the maximum brightness of the device after in situ ligand replacement is 9.2×10 3 . Compared with standard parts, it achieves 10000cd / m 2 The current density is 30.8mA / cm 2 , after in situ ligand replacement, 10000cd / m 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Light emitting area | aaaaa | aaaaa |

| Maximum current efficiency | aaaaa | aaaaa |

| Maximum current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com