Copper-doped bismuth phosphate composite material, and preparation method and application thereof

A composite material, bismuth phosphate technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of restricting the practical application of photocatalytic technology, low solar energy utilization, not very sufficient, etc. , to achieve the effect of excellent photocatalytic performance, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

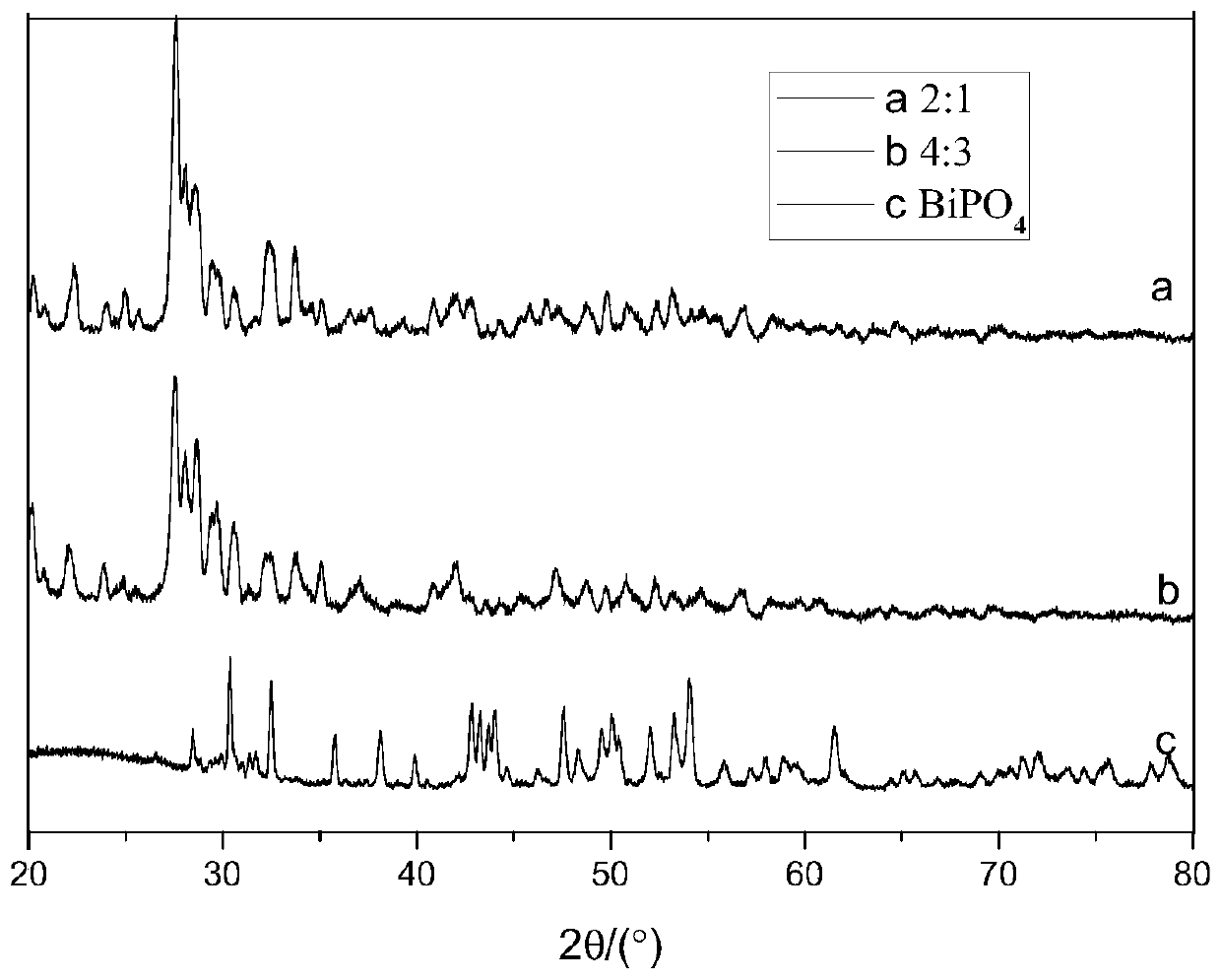

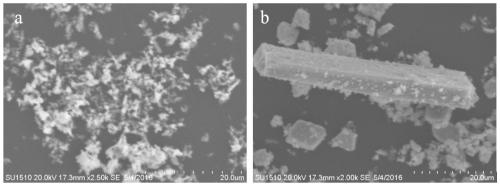

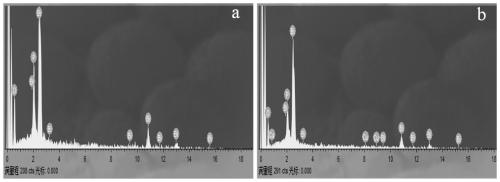

[0029] A preparation method of copper-doped bismuth phosphate composite material, comprising the following steps:

[0030] S1. Add bismuth nitrate and copper nitrate to 30 mL of deionized water, stir for 30 min, then add sodium phosphate, and stir for 30 min to obtain a reaction solution;

[0031] The mol ratio of described bismuth nitrate, copper nitrate and sodium phosphate consumption is 4:3:4;

[0032] S2. Add sodium hydroxide to the reaction solution obtained in S1, adjust the pH value to 7, transfer it to a reaction kettle and seal it, and then react at 180° C. for 24 hours. After the reaction, naturally cool to room temperature, wash, separate, and dry. That is, a copper-doped bismuth phosphate composite material is obtained.

Embodiment 2

[0034] A preparation method of copper-doped bismuth phosphate composite material, comprising the following steps:

[0035] S1. Add bismuth nitrate and copper nitrate to 30 mL of deionized water, stir for 30 min, then add sodium phosphate, and stir for 30 min to obtain a reaction solution;

[0036] The mol ratio of described bismuth nitrate, copper nitrate and sodium phosphate consumption is 1:1:1;

[0037] S2. Add sodium hydroxide to the reaction solution obtained in S1, adjust the pH value to 7, transfer it to a reaction kettle and seal it, and then react at 180° C. for 24 hours. After the reaction, naturally cool to room temperature, wash, separate, and dry. That is, a copper-doped bismuth phosphate composite material is obtained.

Embodiment 3

[0039] A preparation method of copper-doped bismuth phosphate composite material, comprising the following steps:

[0040] S1. Add bismuth nitrate and copper nitrate to 30 mL of deionized water, stir for 30 min, then add sodium phosphate, and stir for 30 min to obtain a reaction solution;

[0041] The mol ratio of described bismuth nitrate, copper nitrate and sodium phosphate consumption is 2:1:2;

[0042] S2. Add sodium hydroxide to the reaction solution obtained in S1, adjust the pH value to 7, transfer it to a reaction kettle and seal it, and then react at 180° C. for 24 hours. After the reaction, naturally cool to room temperature, wash, separate, and dry. That is, a copper-doped bismuth phosphate composite material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com