A kind of road repair material and preparation method thereof

A road and cement technology, applied in the field of road repair materials and their preparation, can solve the problems of slow curing and long-term maintenance, and achieve the effects of stable performance, excellent frost resistance and durability, and good water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

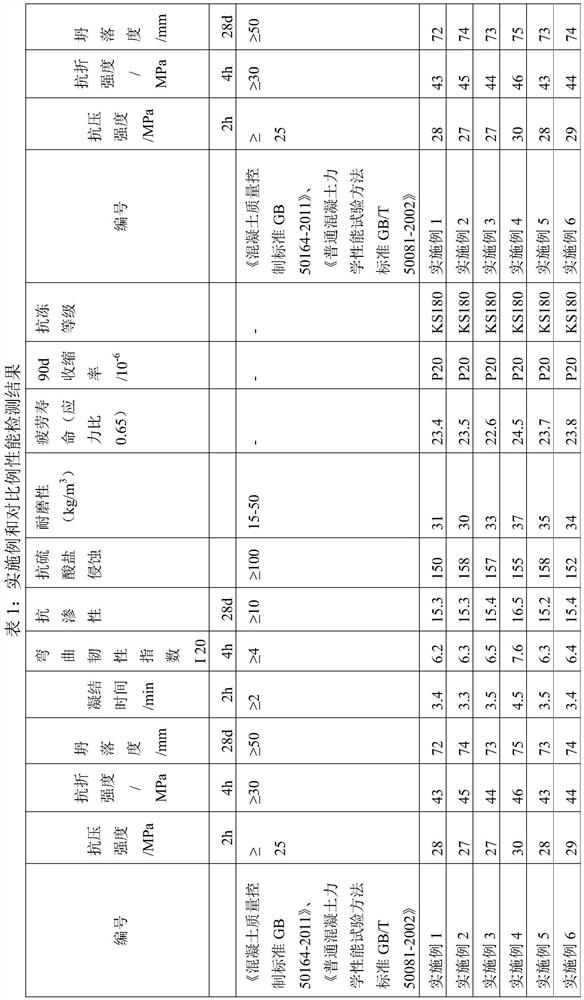

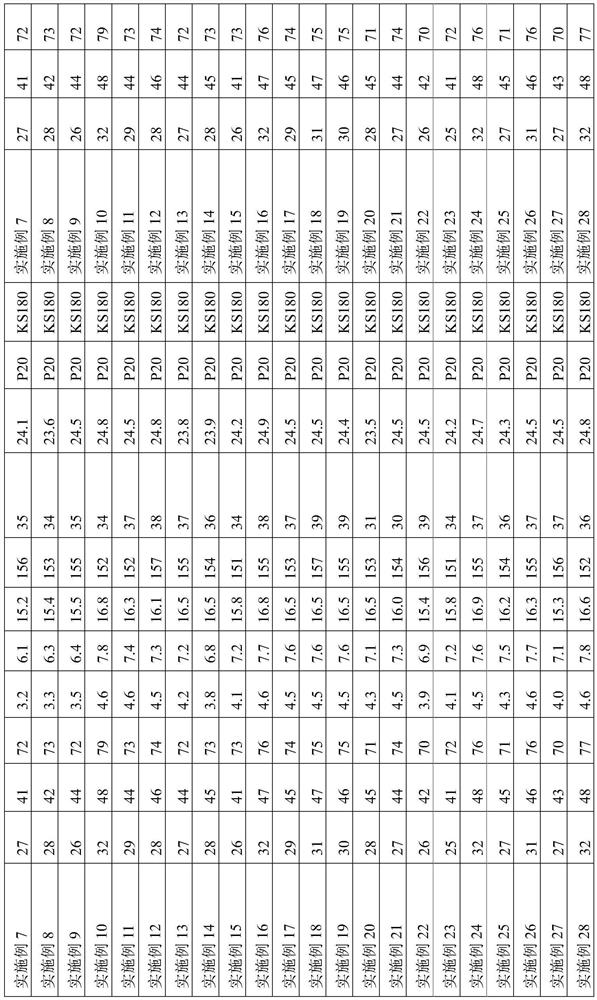

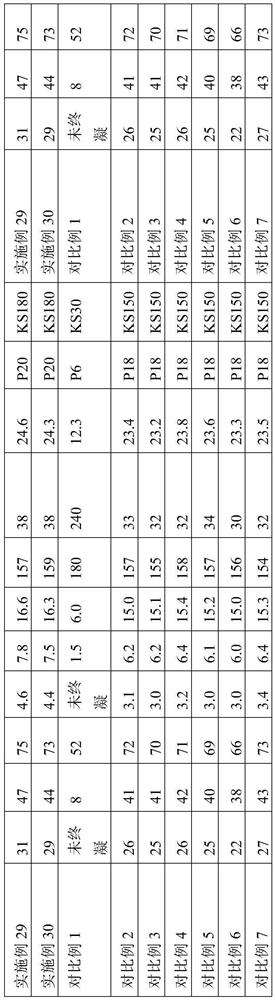

Examples

Embodiment 1

[0053] 1) Prepare the raw materials according to the following proportions by weight:

[0054] 400 parts of cement, 750 parts of sand with a particle size of 0.35-0.50mm, 220 parts of fine gravel with a particle size of 5-10mm, 650 parts of coarse gravel with a particle size of 10-20mm, 90 parts of silica fume with a particle size of 0.1-0.3μm, 4 parts of powder, 1 part of coagulant lithium carbonate, 1 part of retarder sodium tetraborate, 30 parts of steel fiber with aspect ratio of 40-80, 7 parts of polypropylene fiber with fiber length of 3-10mm, fiber length 0.7 parts of 0.5-3mm wood fiber, 0.3 parts of air-entraining agent sodium lauryl sulfate, and 165 parts of water.

[0055] 2) Put the cement, sand, fine gravel, coarse gravel, silica fume, steel fiber, polypropylene fiber, and wood fiber into the dry powder mixer first, and stir for 2-3 minutes;

[0056] 3) Then put the formula amount of powder, coagulant accelerator, coagulant retarder, air-entraining agent and other...

Embodiment 2

[0061] Except preparing raw material by following weight portion proportioning, all the other are with embodiment 1:

[0062] 450 parts of cement, 800 parts of sand, 230 parts of fine gravel, 700 parts of coarse gravel, 100 parts of silica fume, 5 parts of powder, 3 parts of accelerator, 1 part of retarder, 25 parts of steel fiber, polypropylene fiber 7 parts, 0.7 parts of wood fiber, 0.3 parts of air-entraining agent, and 170 parts of water.

Embodiment 3

[0064] Except preparing raw material by following weight portion proportioning, all the other are with embodiment 1:

[0065] 480 parts of cement, 810 parts of sand, 240 parts of fine gravel, 750 parts of coarse gravel, 85 parts of silica fume, 5 parts of powder, 3 parts of coagulant, 1 part of retarder, 30 parts of steel fiber, polypropylene fiber 7 parts, 0.7 parts of wood fiber, 0.3 parts of air-entraining agent, and 172 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com