Amphipathic conjugated polymer and production method and application thereof

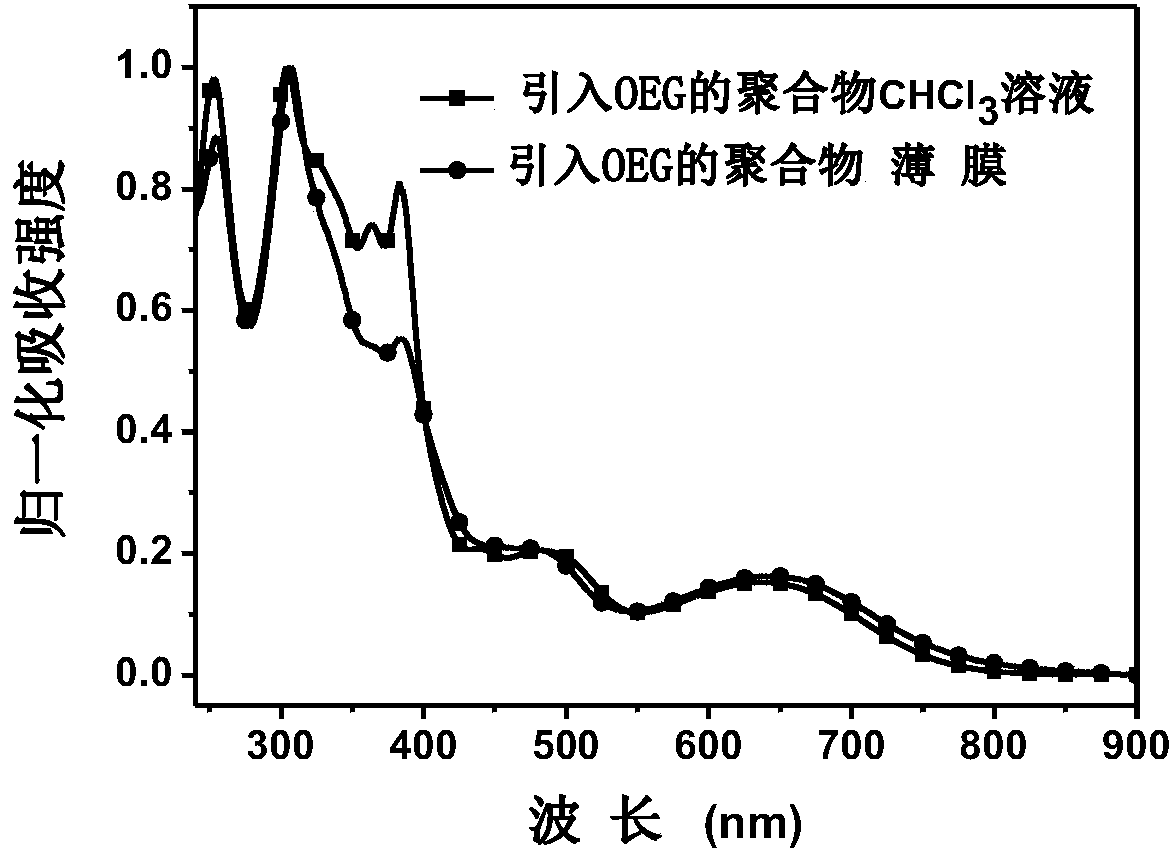

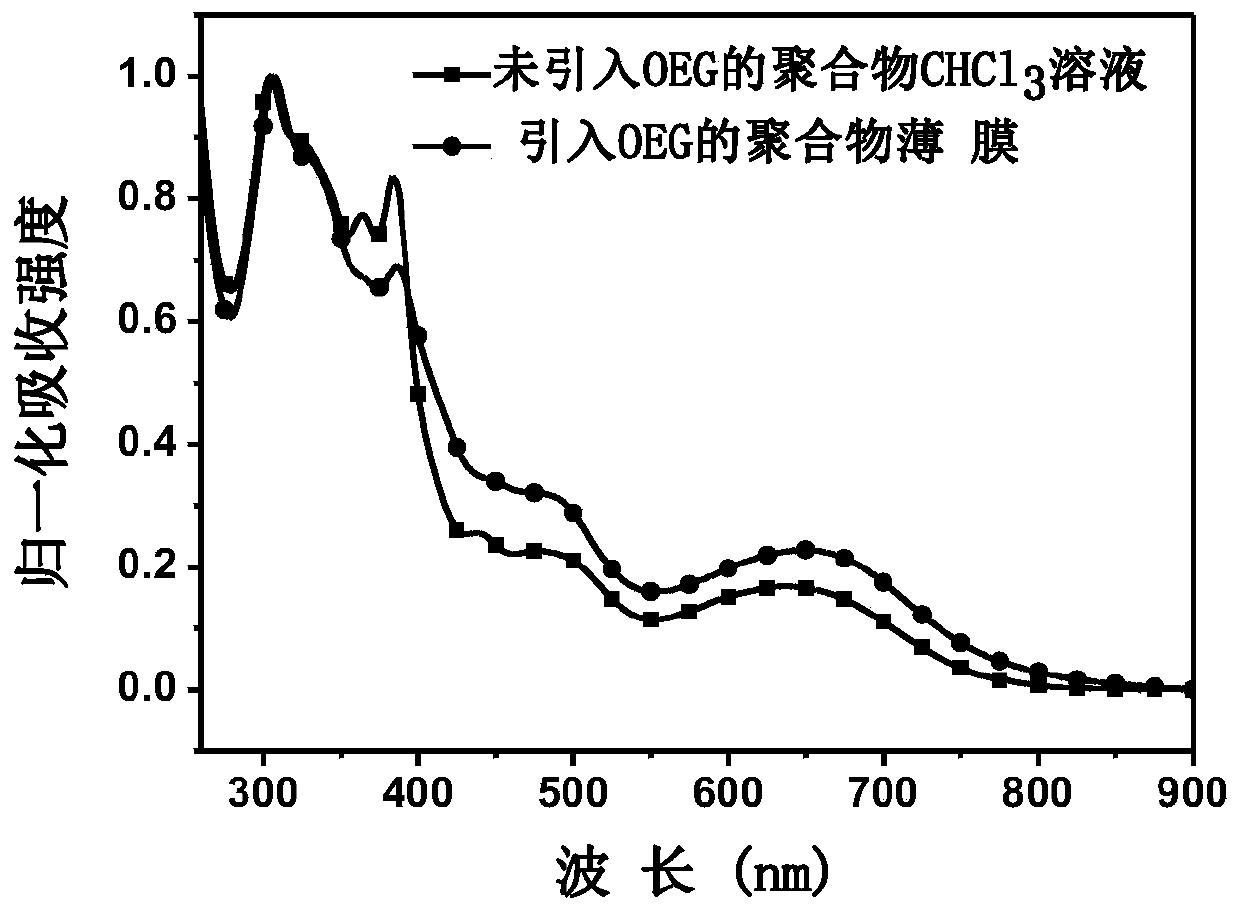

A conjugated polymer and amphiphilic technology, which is applied in the field of amphiphilic conjugated polymers and their preparation, can solve the problems of difficult design, complex structure, and high cost of structural skeleton units, and achieves improved microscopic phase separation and good phase separation. Separation scale, effect of high short-circuit current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]

[0041] target compound T 1

[0042] 【Reaction route】

[0043]

[0044] Dimethyltin-4,8-bis((5-hexyloctyl)thiophene)benzodithiophene (0.08mmol, 80mg), 2,6-dibromo-2-octanedecanenaphthalimide (0.056mmol, 96mg), join together in the 25mL Kleiner reaction tube, in the reaction tube, keep nitrogen atmosphere, add catalyst Pd 2 (dba) 3 (0.004mmol, 3.6mg), Ligand P(o-tol) 3(0.0096, 10 mg) and then maintain the nitrogen atmosphere again. Prepare 2,6-dibromo-tetrapolyethylene glycol naphthalimide with anhydrous toluene solvent to prepare a 10mg / mL solution, and after passing nitrogen gas for 15min, add 2mL of the solution to the reaction tube, and then add 3mL of anhydrous Purify toluene, control the temperature at 110°C, stir and heat the reaction mixture for 32h. Added 2-bromothiophene (0.084 mmol, 20mg), heated for 6h, added 2-butyltinthiophene (0.168mmol, 60mg), then kept heating for 6h, and finally cooled to room temperature. The reactant was settled in a met...

Embodiment 2

[0048]

[0049] target compound T 2

[0050] 【Reaction route】

[0051]

[0052]

[0053] Dimethyltin-4,8-bis((5-hexyloctyl)thiophene)benzodithiophene (0.08mmol, 80mg), 2,6-dibromo-2-octanedecanenaphthalimide (0.072mmol, 90mg), join together in the 25mL Kleiner reaction tube, in the reaction tube, keep nitrogen atmosphere, add catalyst Pd 2 (dba) 3 (0.0024mmol, 2mg), Ligand P(o-tol) 3 (0.008mmol, 8mg) and then maintain the nitrogen atmosphere again. Prepare 2,6-dibromo-tripolyethylene glycol naphthalimide with anhydrous toluene solvent to form an 8mg / mL solution, and after passing nitrogen gas for 15min, add 1mL of the solution to the reaction tube, and then add 4mL of Water was used to purify toluene, the temperature was controlled at 110°C, and the reaction mixture was stirred and heated for 40 hours. Add 2-bromothiophene (0.09mmol, 25mg), after heating for 6h, add 2-butyltinthiophene (0.120mmol, 50mg), keep heating for 6h, and finally cool to room temperature...

Embodiment 3

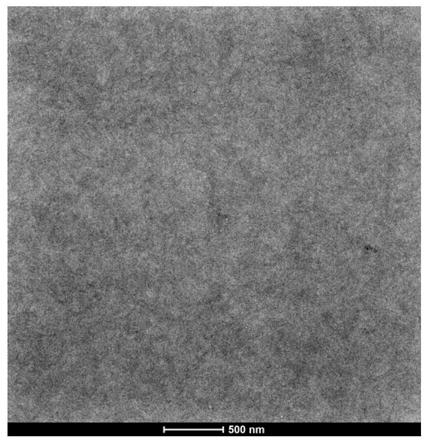

[0055] Preparation of ternary organic solar cells with inverted structure, binary device structure ITO / ZnO / PBDB-T: target compound T1 / MoO in Example 1 3 / Ag, the process is as follows:

[0056] (1) Use an ITO electrode with a square resistance of about 15Ω for cleaning, and then use detergent, deionized water, acetone, and isopropanol to clean it ultrasonically for 15 minutes, then blow it dry with nitrogen, and immediately clean it with a UV cleaner for 10 minutes after drying .

[0057] (2) Use absolute ethanol as the solvent and zinc acetate as the solute to prepare a solution of 80 mg / mL, then add 28 μL of ethanolamine to each milliliter of the solution, stir for 24 hours to form a ZnO precursor solution, spin-coat at 4500 rpm for 30 seconds, 200 ℃ annealing for 30min to form a zinc oxide interface layer.

[0058] (3) Transfer the annealed ITO substrate to the glove box, spin-coat the active layer on the ZnO film, and dissolve the active layer material with a binary dono...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com