Mirror surface-level high-precision metal working oil suitable for high-light processing technology and preparation method thereof

A technology for metal processing oil and processing technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of scratching products, affecting the production progress of product quality, difficult to improve the mirror effect of high-gloss processing, etc., so as to improve the brightness and mirror surface. effect, effect of long-term effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

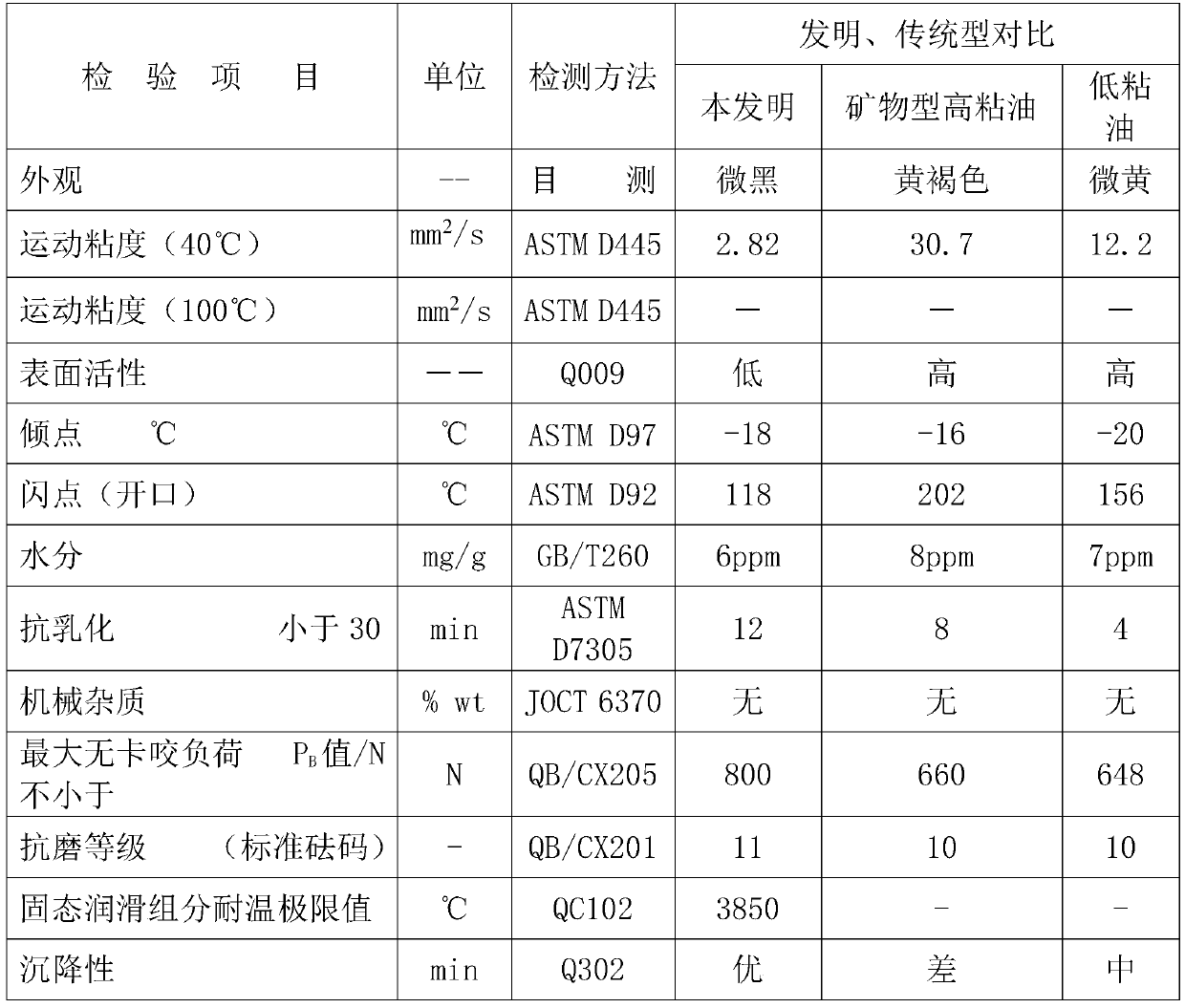

Image

Examples

preparation example Construction

[0021] This embodiment also discloses a preparation method of mirror-grade high-precision metal processing oil suitable for high-gloss processing technology, including the following steps:

[0022] a. Pre-disperse Span 80 and graphene in part of EDM oil and then mix and stir with the remaining EDM oil; preferably, pre-disperse and stir graphene in 5 times (weight) of EDM oil Uniform; pre-disperse Span 80 and petroleum calcium sulfonate T106 in 3 times (weight) EDM engine oil and stir evenly.

[0023] b. Heating the mixture in step a to 40-60°C, adding the remaining materials and then continuously stirring and reacting for more than 2 hours at a temperature of 40-60°C;

[0024] Further, in step a, mix and stir Span 80 and alkali retaining agent with part of EDM oil; mix and stir graphene with part of EDM oil; finally, add the above two pre-mixed materials to the remaining Stir well in EDM engine oil.

Embodiment 1

[0026] The mirror-grade high-precision metalworking oil suitable for the high-gloss processing technology of this embodiment includes the following components by weight: 80 parts of EDM engine oil, 0.3 part of polyisobutylene, 0.2 part of graphene, 0.5 part of T154, petroleum sulfonic acid 0.5 part of calcium, 0.2 part of phosphoric acid ester, 6 parts of Span 80, 0.2 part of Tween 80; the preparation method comprises the following steps: a. mixing and stirring Span 80 and petroleum calcium sulfonate with part of electric spark engine oil; Mix with part of the EDM oil and stir evenly; finally, add the above two pre-mixed materials into the remaining EDM oil and stir evenly;

[0027] b. The temperature of the mixed material in step a was raised to 40° C., and then the remaining materials were added, and the reaction was continuously stirred at a temperature of 40° C. for 2 hours.

Embodiment 2

[0029] The mirror-grade high-precision metal processing oil suitable for the high-gloss processing technology of this embodiment includes the following components by weight: 90 parts of EDM engine oil, 2 parts of polyisobutylene, 5 parts of graphene, 3 parts of T154, petroleum sulfonic acid 3 parts of calcium, 1.5 parts of phosphate ester, 12 parts of Span 80, and 1 part of Tween 80; the preparation method comprises the following steps: a. mixing and stirring Span 80 and petroleum calcium sulfonate with part of electric spark engine oil; Mix with part of the EDM oil and stir evenly; finally, add the above two pre-mixed materials into the remaining EDM oil and stir evenly;

[0030] b. The temperature of the mixture in step a was raised to 60° C., and then the rest of the materials were added, and the reaction was continuously stirred at 60° C. for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com