Automatic evaluation device for tribological property of lubricating thin film

A technology of lubricating film and evaluation device, which is applied in measuring devices, mechanical devices, scientific instruments, etc., can solve the problems of complex process of lubricating film composite materials, save manpower and material resources, speed up evaluation process, and promote the effect of replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

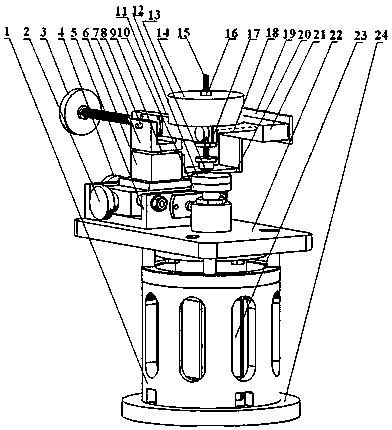

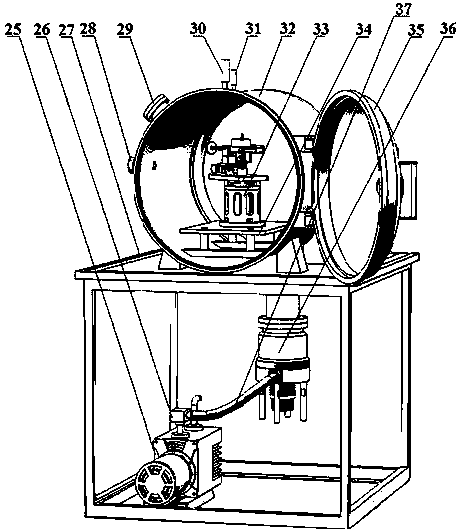

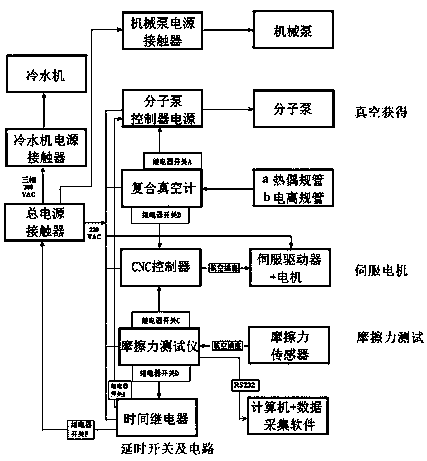

[0022] The invention consists of a friction testing machine, a friction test, a vacuum system, a servo motor and electrical control.

[0023] see figure 1 , the friction testing machine is equipped with an upper and a lower group of friction pair samples, the upper sample 13 is a rigid friction pair whose lower end surface is a spherical surface, and it is clamped at the lower end of the friction pair fixture 17; The lower end of the rod 15 is fixedly connected, and the weight 14 required for loading is installed on the threaded rod 15 for application of force and is fixed by a fixed nut 16; The support shaft I8 with bearings is installed on the balance bar support platform II7, the balance bar support platform II7 is installed on the balance bar support platform I6 through the support shaft II9 equipped with bearings, and the balance bar support platform I6 is fixed on the positioning platform 5; Adjust the positioning nut II4 on the positioning platform 5 to realize the rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com