Thick film resistor paste used for ceramic piezoresistive-type pressure sensor and preparation method

A pressure sensor and thick film resistor technology, applied in the field of thick film resistor paste and preparation for ceramic piezoresistive pressure sensors, can solve the problems of poor stability, low strain coefficient, large resistance value, etc., achieve high stability, improve The effect of gage factor and resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

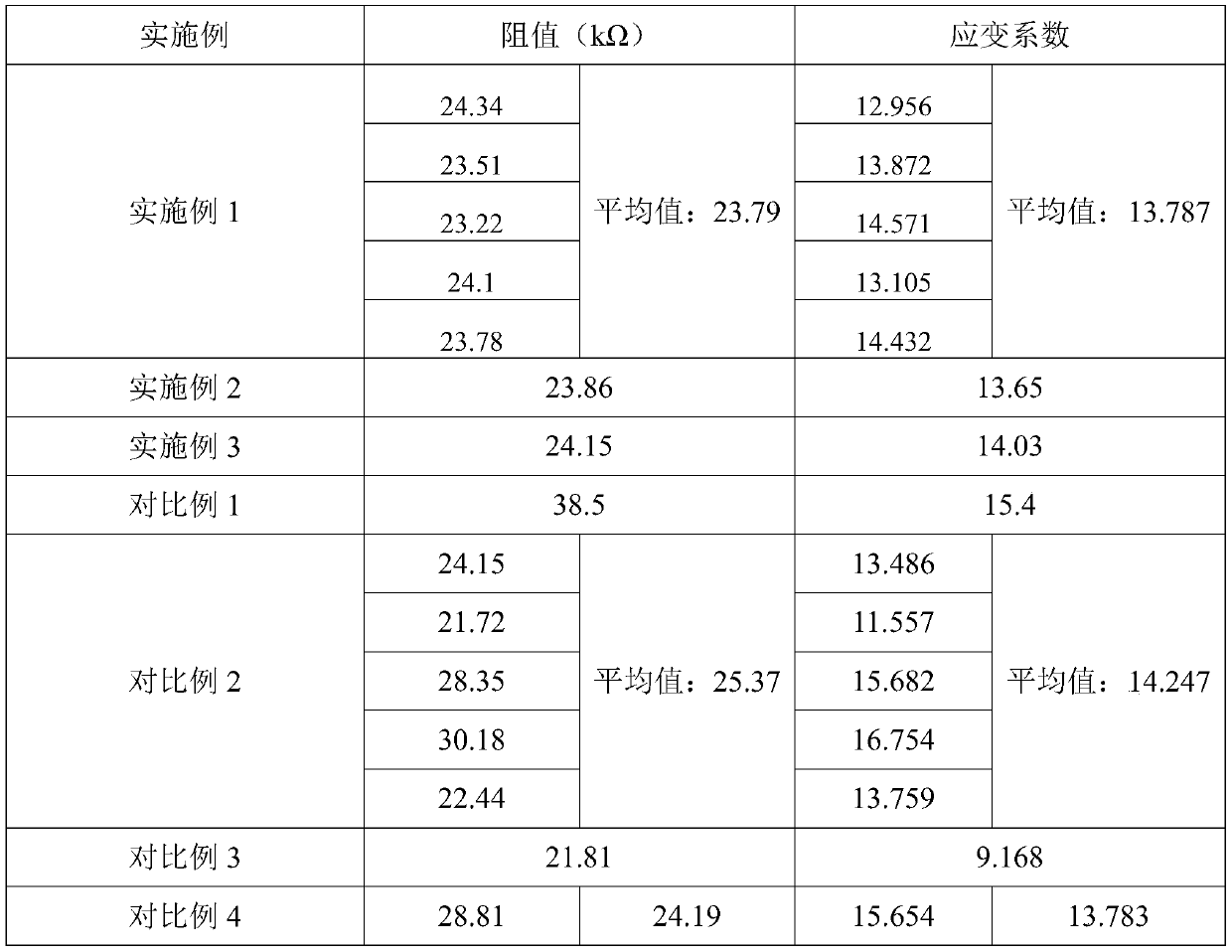

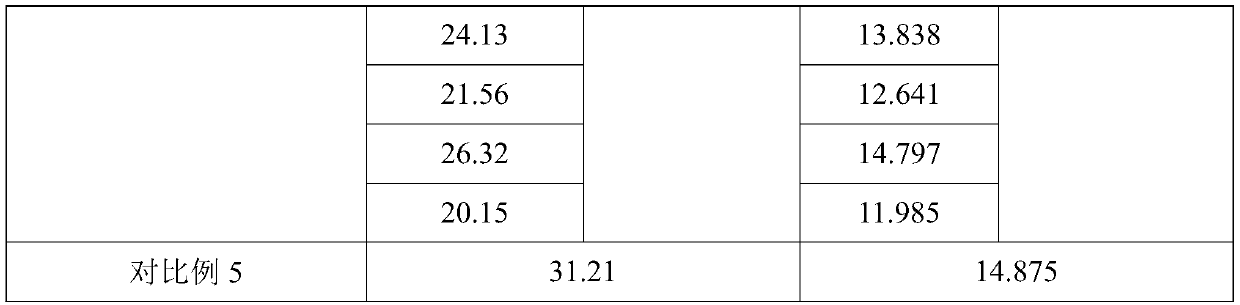

Embodiment 1

[0030] Embodiment 1: A kind of preparation method of ceramic piezoresistive pressure sensor thick-film resistance slurry comprises the following preparation steps:

[0031] S1: Preparation of conductive phase:

[0032] S1.1: Add deionized water to 1.5g of ruthenium trichloride to make a 0.1mol / L ruthenium trichloride solution, then add 1.5g of carbon nanotubes, raise the temperature to 60°C and stir, then add hydrogen drop by drop Sodium oxide solution, continue to stir and age for 2h, then centrifuge and wash, and calcinate at 300°C for 20h to obtain a ruthenium oxide / carbon nanotube composite material;

[0033] S1.2: Mix 28.8g of ruthenium oxide powder with 2.4g of ruthenium oxide / carbon nanotube composite material to prepare a conductive phase;

[0034] S2: Preparation of inorganic binder phase: CaO, B 2 o 3 , SiO 2 and ZrO 2 According to the ratio of 5:4.5:5.5:1.5, add it to the agate ball mill jar and stir for 1 hour, then place it in a crucible and melt it at 1100°C f...

Embodiment 2

[0040] Embodiment 2: A kind of preparation method of ceramic piezoresistive pressure sensor thick-film resistance slurry comprises the following preparation steps:

[0041] S1: Preparation of conductive phase:

[0042] S1.1: Add deionized water to 3.1g ruthenium trichloride to make a 0.13mol / L ruthenium trichloride solution, then add 1.45g carbon nanotubes, heat up to 65°C and stir, then add hydrogen drop by drop Sodium oxide solution, continue to stir and age for 3 hours, then centrifuge and wash, and calcinate at 250°C for 24 hours to obtain a ruthenium oxide / carbon nanotube composite material;

[0043] S1.2: Mix 26.7g of ruthenium oxide powder with 3.8g of ruthenium oxide / carbon nanotube composite material to prepare a conductive phase;

[0044] S2: Preparation of inorganic binder phase: CaO, B 2 o 3 , SiO 2 and ZrO 2 According to the ratio of 4:5:5:2, add it to the agate ball mill jar and stir for 2 hours, then place it in a crucible and melt it at 1300°C for 1.5 hour...

Embodiment 3

[0050] Embodiment 3: A kind of preparation method of ceramic piezoresistive pressure sensor thick-film resistance paste, comprises the following preparation steps:

[0051] S1: Preparation of conductive phase:

[0052] S1.1: Add deionized water to 3.9g of ruthenium trichloride to make a 0.15mol / L ruthenium trichloride solution, then add 1.36g of carbon nanotubes, heat up to 70°C and stir, then add hydrogen drop by drop Sodium oxide solution, continue to stir and age for 4 hours, then centrifuge and wash, and calcinate at 350°C for 15 hours to obtain a ruthenium oxide / carbon nanotube composite material;

[0053] S1.2: Mix 21.3g of ruthenium oxide powder with 4.3g of ruthenium oxide / carbon nanotube composite material to prepare a conductive phase;

[0054] S2: Preparation of inorganic binder phase: CaO, B 2 o 3 , SiO 2 and ZrO 2 According to the ratio of 4.5:4:4.5:1.8, it was added to the agate ball milling tank and stirred for 1.5 hours, then placed in a crucible and melte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com