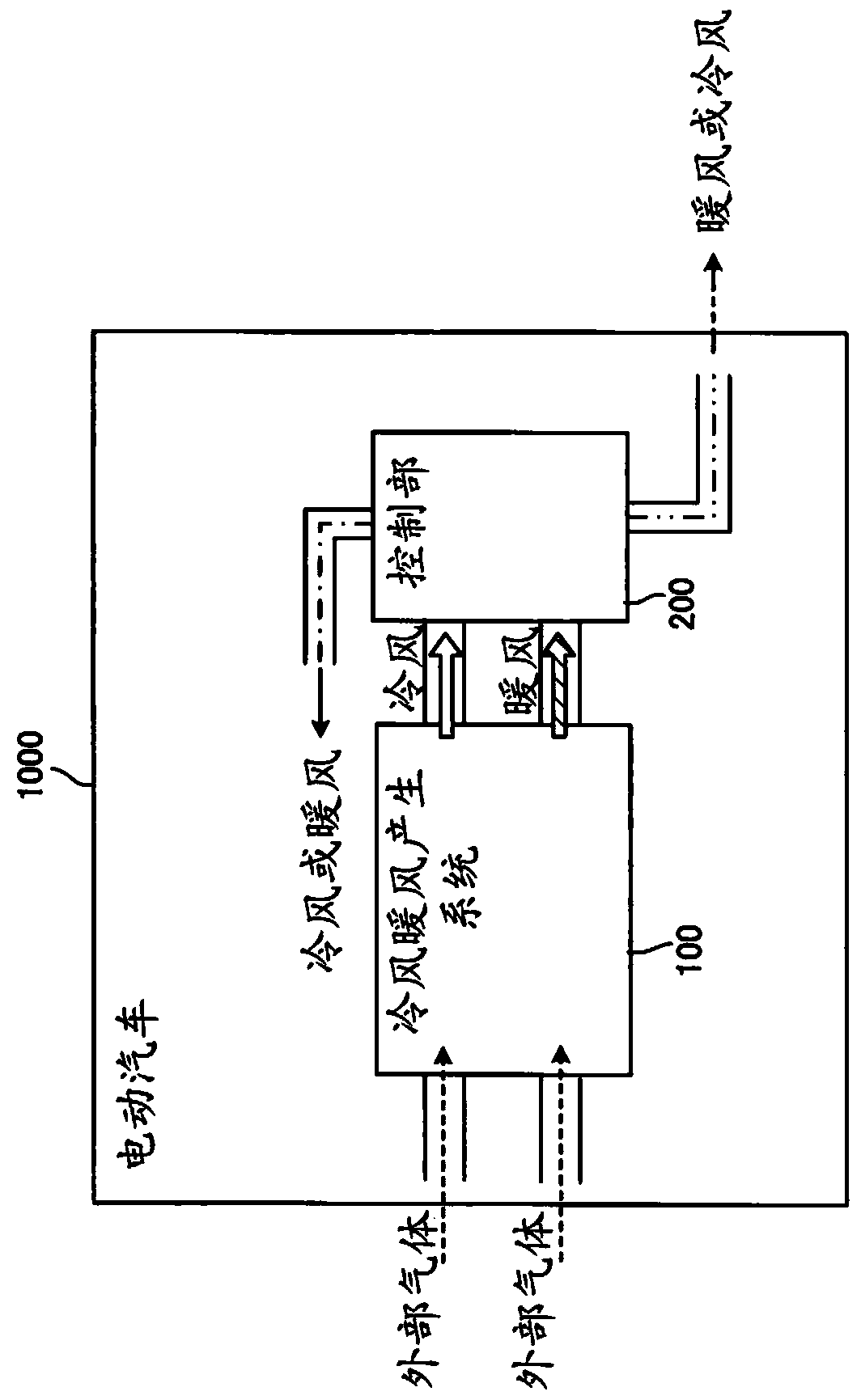

Cool air/warm air generation system

A warm air and cold air technology, which is applied in the direction of mechanical power generation mechanism, refrigerator, refrigeration and liquefaction, etc., can solve the problems of complex mechanism, easy to enlarge the device, and great adverse effect of global warming, etc., to achieve energy efficiency, The effect of high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

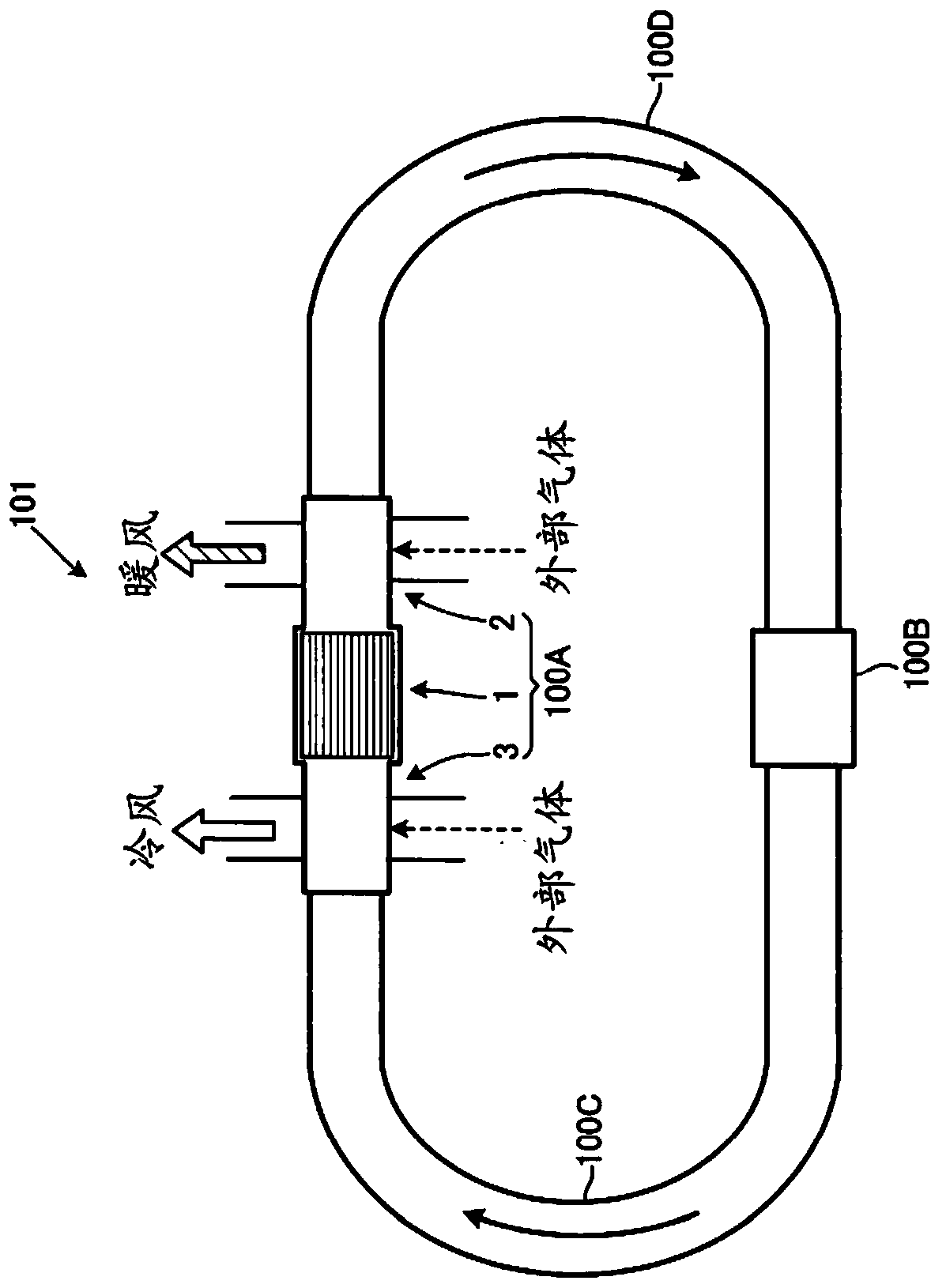

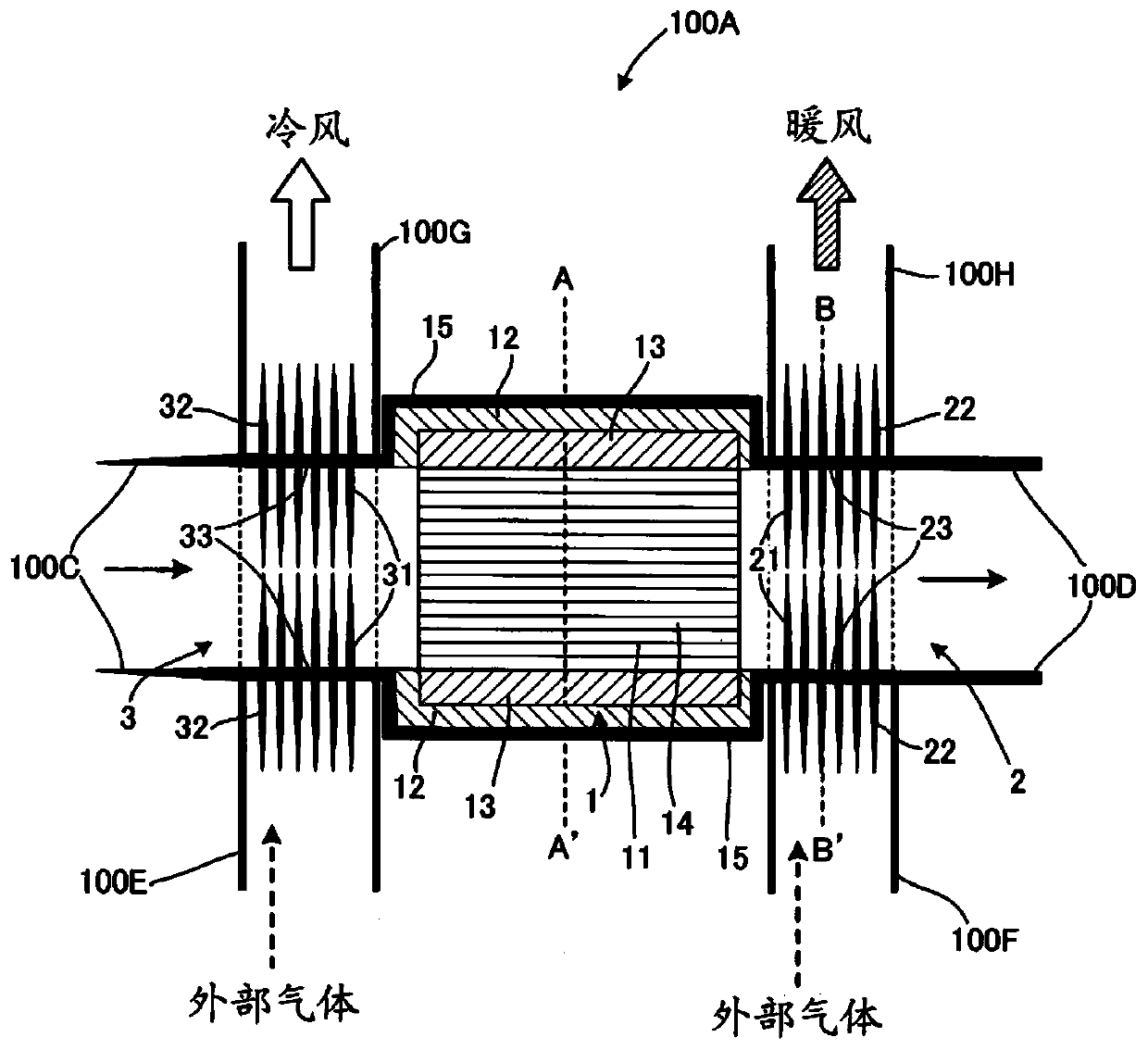

[0210] Example 1 uses the image 3 and Figure 4 100A of cold and warm wind generators and Figure 10 The sound wave generating part 100B of the figure 2 A specific example of the cold and warm wind generation system 101.

[0211] First, the cold air warm air generator in the first embodiment will be described. First, the thermoacoustic wave converting part of the cold air and warm air generating unit will be described.

[0212] As the thermoacoustic wave conversion member of the cold and warm air generation unit in Example 1, a honeycomb structure was used in which both the partition wall and the outer peripheral wall were made of a cordierite material with a thermal conductivity of 1.0 W / mK, and each cell was extended. In the cross-section of the entire thermoacoustic wave conversion member perpendicular to the direction of , the cell density of the area (cell structure area) occupied by the cross-section of the partition wall and the cross-section of the cell is 775 ce...

Embodiment 2~3 and comparative example 1~2

[0240] Except that the die used in the extrusion molding of the thermoacoustic wave conversion part is different, the same method as in the above-mentioned Example 1 is used to produce the thermoacoustic wave conversion part. The value of the cell density in the cell structure region is different from that of Example 1. The cold wind and warm wind generating systems of Examples 2-3 and Comparative Examples 1-2. Then, by the same method as in Example 1, energy efficiency, the degree of compactness, and the amount of noise were obtained and evaluated.

[0241] The evaluation results of Examples 1 to 3 and Comparative Examples 1 to 2 are shown in Table 1 below together with the values of the above-mentioned parameters that characterize these Examples and Comparative Examples.

[0242] [Table 1]

[0243]

[0244] In Table 1, comparing Examples 1-3 and Comparative Example 2 shows that the energy efficiency and compactness of Examples 1-3 are very high compared with Comparativ...

Embodiment 4~5 and comparative example 3

[0246] In the manufacturing method of the thermoacoustic wave conversion member, except that the ceramic raw material is different, the same method as that of the above-mentioned Example 1 is used to produce a thermoacoustic wave conversion member that is different from that of Example 1 only in the thermal conductivity of the constituent materials of the partition wall or the outer peripheral wall. The cold wind and warm wind generation systems of Examples 4-5 and Comparative Example 3. Specifically, in Examples 4 to 5 and Comparative Example 3, the thermal conductivity was different from that of Example 1 by changing the proportions of talc, kaolin, alumina, and boehmite in Example 1.

[0247] The evaluation results of Examples 1, 4 to 5, and Comparative Example 3 are shown in Table 2 below together with the values of the above-mentioned parameters that characterize these Examples and Comparative Examples.

[0248] [Table 2]

[0249]

[0250] In Table 2, comparing Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com