Patch containing isosorbide dinitrate

A technology of isosorbide and dinitrate, applied in the direction of drug combination, cardiovascular system diseases, active ingredients of heterocyclic compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

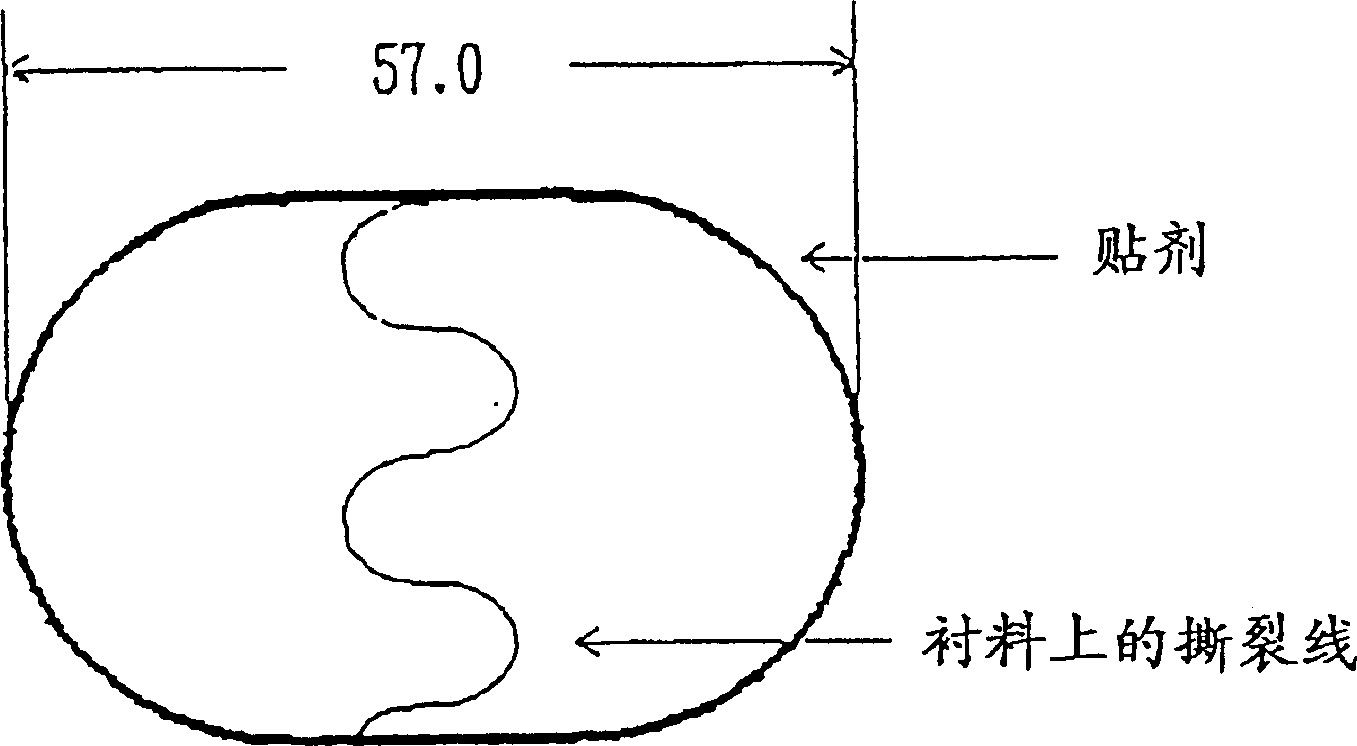

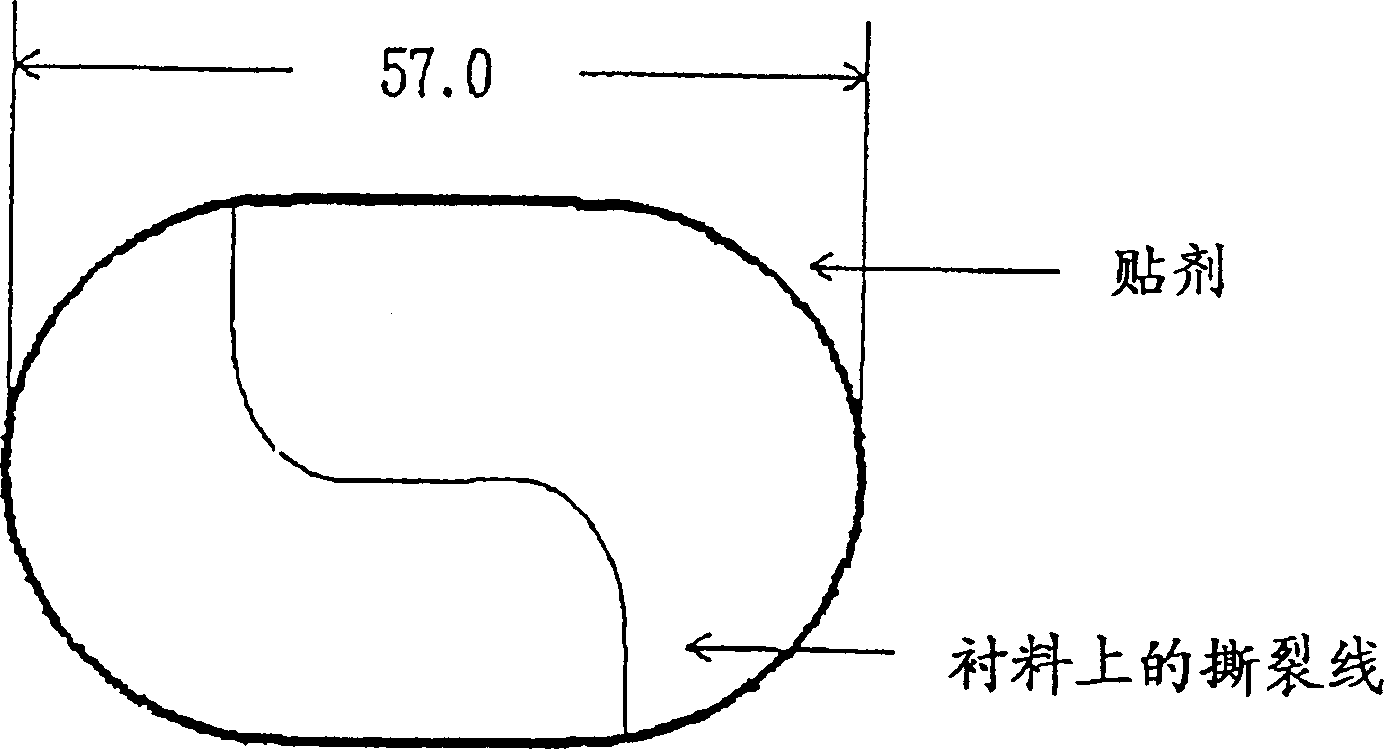

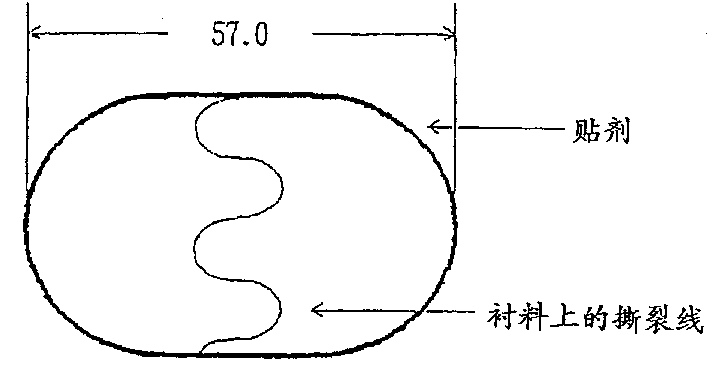

Image

Examples

Embodiment 1

[0150] 87.5 parts of polyvinyl acetate binder solution (coating solution B), 87.5 parts of acrylic binder solution (coating solution A), 35 parts of isopropyl myristate (C), 30 parts of isosorbide dinitrate Ester (D), 193 parts of ethyl acetate and 0.14 parts of aluminum acetylacetonate were mixed to an almost uniform state, and the resulting mixture was used to coat a 75 μm thick polyethylene terephthalate spacer (Japanese Pharmaceutical Excipient Forming agent) so that the thickness after drying is 45 μm, it is fully dried, and the residual ethyl acetate becomes 100 ppm or less to obtain a drug storage layer. A polyethylene terephthalate film (PET film, Teijin film F3 type) having a thickness of 2.0 μm was pressed so as to be bonded to the free surface of a drug reservoir layer having a thickness of 45 μm containing 30% by weight of isosorbide dinitrate .

[0151] In addition, after mixing 117.5 parts of coating solution B, 117.5 parts of coating solution A, 35 parts of iso...

Embodiment 3

[0158] Mix 60 parts of coating solution B, 140 parts of coating solution A, 30 parts of isopropyl myristate (C), 30 parts of isosorbide dinitrate (D), 140 parts of ethyl acetate and 0.16 parts of aluminum acetylacetonate to almost After a uniform state, the formed mixture was coated with a polyethylene terephthalate separator (Japanese pharmaceutical excipient) with a thickness of 75 μm to a thickness of 53 μm after drying, and it was fully dried, and the remaining Vinyl acetate becomes 100 ppm or less to obtain a binder.

[0159] A polyethylene terephthalate film (Teijin film F3 type) having a thickness of 2.0 μm was pressed to be bonded to the free surface of the adhesive layer containing 30% by weight of isosorbide dinitrate to obtain a crude fabric patch. Cut the rough fabric patch to size 25cm 2 (long 3.5cm, wide 7.1cm), obtain the 25cm that contains 40mg isosorbide dinitrate 2 Patches (TC-3). TC-3 was evaluated as in Example 1, and the results are listed in Table 1. ...

Embodiment 4

[0159] A polyethylene terephthalate film (Teijin film F3 type) having a thickness of 2.0 μm was pressed to be bonded to the free surface of the adhesive layer containing 30% by weight of isosorbide dinitrate to obtain a crude fabric patch. Cut the rough fabric patch to size 25cm 2 (long 3.5cm, wide 7.1cm), obtain the 25cm that contains 40mg isosorbide dinitrate 2 Patches (TC-3). TC-3 was evaluated as in Example 1, and the results are listed in Table 1. [Example 4 and Comparative Examples 1-10]

[0160] The weight ratio of A, B, C and D of embodiment 3 is changed into as shown in table 1, obtains patch (embodiment 4 and comparative example 1-10) in the same manner as embodiment 3, and evaluation result is listed in in FIG. 1.

[0161] As can be seen from the results of Experiments 1 to 4 shown in Table 1, the specific combination of A, B, C, and D gave extremely high transdermal absorption levels, and especially under the conditions of Experiments 1 and 2, the patch had a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com