A kind of amorphous alloy, its laser welding method and welding auxiliary device

An amorphous alloy, laser welding technology, used in laser welding equipment, welding equipment, metal processing equipment and other directions, to avoid crystallization problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

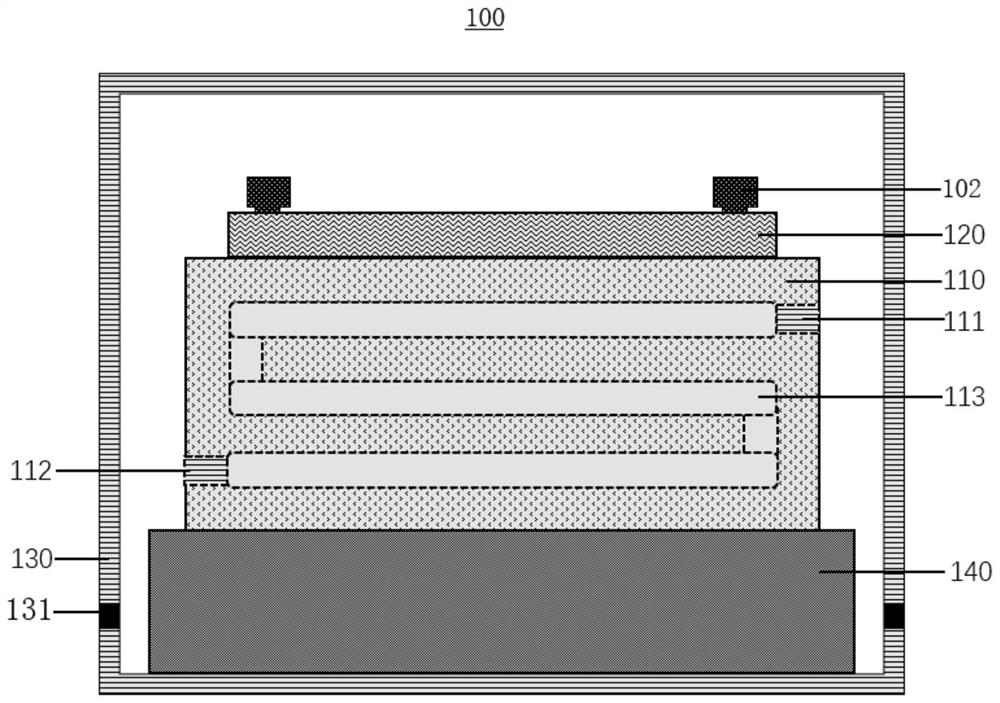

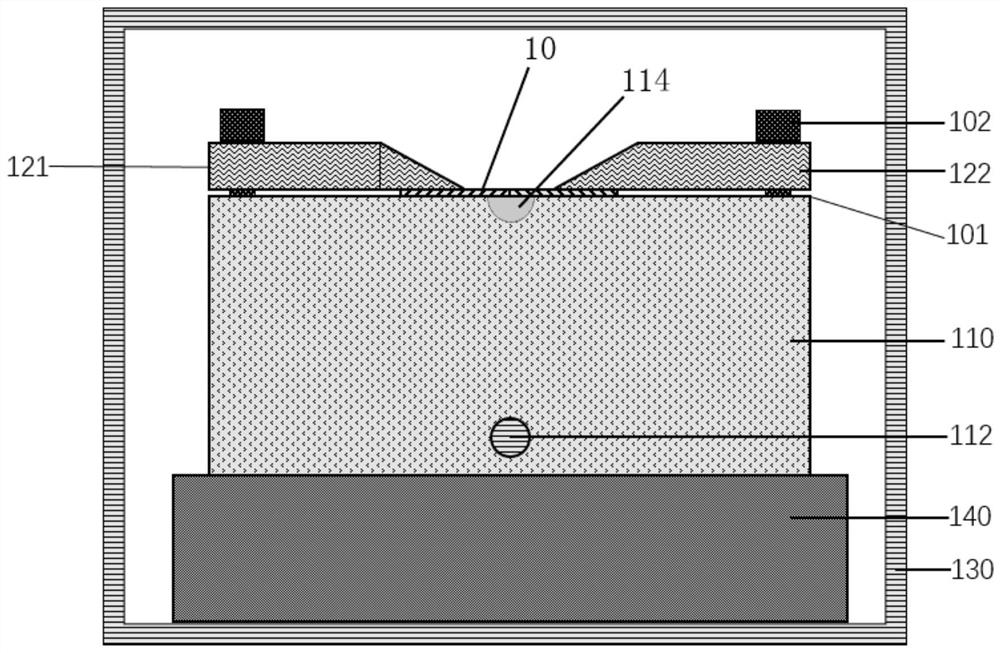

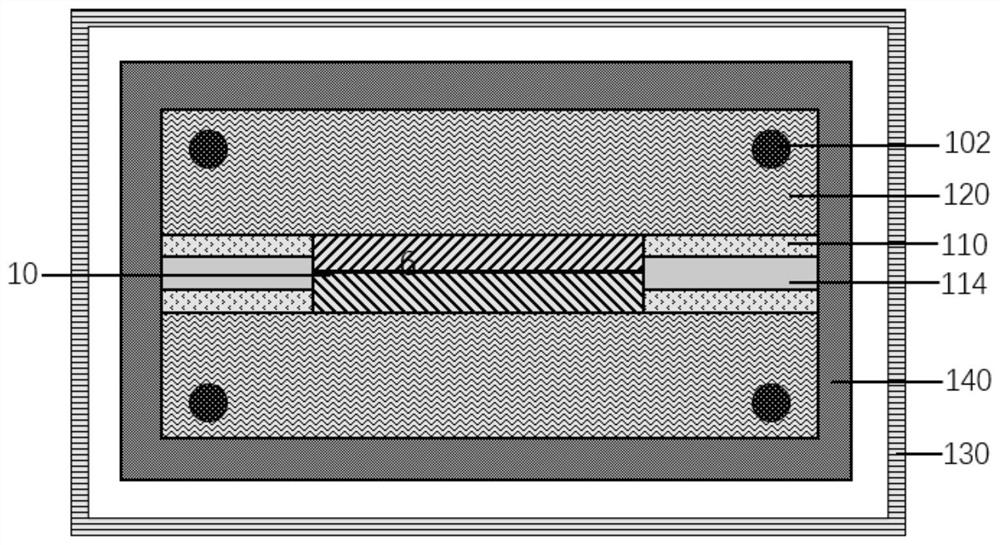

[0050] The present embodiment provides a method for laser welding of amorphous alloys, which includes the following steps:

[0051] (1) The amorphous alloy was polished with 240-mesh, 1000-mesh, and 2000-mesh sandpaper in sequence, then immersed in absolute ethanol, and ultrasonically oscillated for 3 minutes. (2) Clamp the two zirconium-based alloy parts to be welded with a thickness of 1mm on the welding platform of the main body of the cooling device (made of brass), align the weld seam with the weld seam groove, and clamp and fix it with clamps and screws . (3) Connect the water inlet and outlet of the main body of the cooling device with the compressor, and pass the cooling water into the internal pipeline in the cooling device to form a circulation circuit. The temperature of the cooling water is 10°C. (4) Pass argon gas into the casing from the air inlet, and continue to inhale for 10 minutes, and wait until the air in the device is completely exhausted. (5) Laser wel...

Embodiment 2

[0053] The present embodiment provides a method for laser welding of amorphous alloys, which includes the following steps:

[0054] (1) Clamp two magnesium-based alloy parts to be welded with a thickness of 1mm on the welding platform of the main body of the cooling device (the material is gold), align the weld seam with the weld seam groove, and clamp and fix it with clamps and screws. (2) Connect the water inlet and outlet of the main body of the cooling device with the compressor, and pass the cooling liquid nitrogen into the internal pipeline in the cooling device to form a circulation circuit. The temperature of the cooling water is 20°C. (3) Pass argon gas into the housing from the air inlet, and continue to inhale for 20 minutes, and wait until the air in the device is completely exhausted. (4) Carry out laser welding, the laser is incident on the weld seam from the empty slot above the shell, argon gas is continuously fed into the welding process, the laser power is 75...

Embodiment 3

[0056] The present embodiment provides a method for laser welding of amorphous alloys, which includes the following steps:

[0057] (1) The amorphous alloy was polished with 240-mesh, 1000-mesh, and 2000-mesh sandpaper in sequence, then immersed in absolute ethanol, and ultrasonically oscillated for 5 minutes. (2) Clamp two iron-based alloy parts to be welded with a thickness of 2mm on the welding platform of the main body of the cooling device (made of copper), align the weld seam with the weld seam groove, and clamp and fix it with clamps and screws. (3) Connect the water inlet and outlet of the main body of the cooling device with the compressor, and pass the cooling water into the internal pipeline in the cooling device to form a circulation circuit. The temperature of the cooling water is 10°C. (4) Pass argon gas into the casing from the air inlet, and continue to inhale for 10 minutes, and wait until the air in the device is completely exhausted. (5) Laser welding is ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com