Method used for processing refined cotton black liquor with waste alkali waste heat

A waste heat treatment and cotton refining technology, which is applied in water treatment parameter control, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of high cost, difficult application, complex treatment technology and process, and achieve rapid treatment and environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) During the treatment process of the refined cotton black liquor, the refined cotton black liquor is first adjusted to the optimum temperature and alkalinity in the adjustment pool 1. The cotton black liquor flows into the reciprocating partition reaction tank 2 through the pump or the liquid level difference.

[0038] (2) Temperature sensor B 9 and pH sensor B 10 transmit the temperature and pH data of processing refined cotton black liquor in the partition reaction tank 2 to the controller 7, and the controller 7 can adjust the dropper 8 according to the actual temperature and pH The velocity of flow, of which every 1m 3 Add 40L ~ 60L, 2mmol / L ~ 4mmol / L PS or PMS solution to the refined cotton black liquor, and the PS or PMS solution added dropwise to the partition reaction tank 2 is quickly activated by the waste heat and alkali in the refined cotton black liquor Strong oxidizing SO 4 - · and HO ·, when the refined cotton black liquor reciprocates in the partit...

Embodiment 2

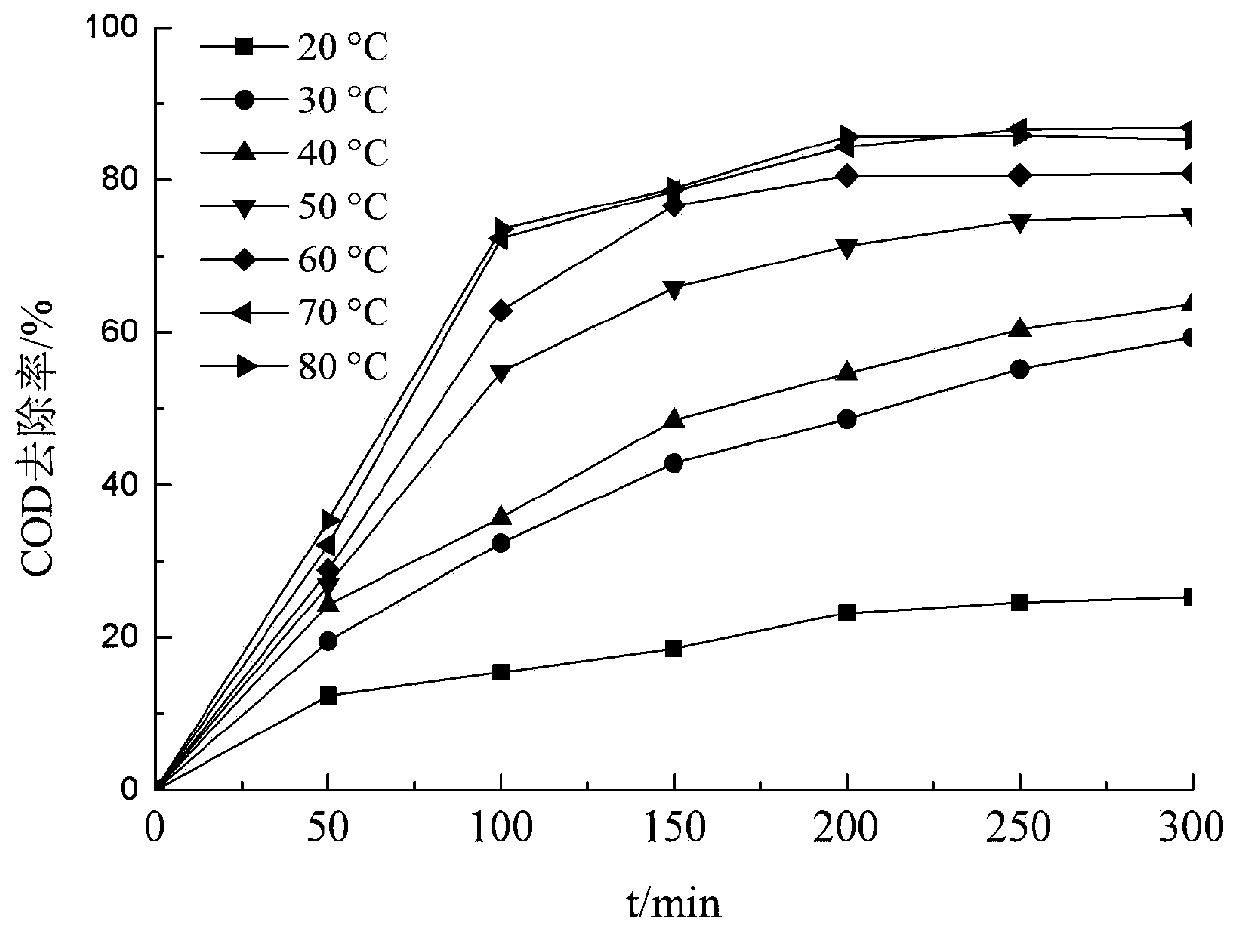

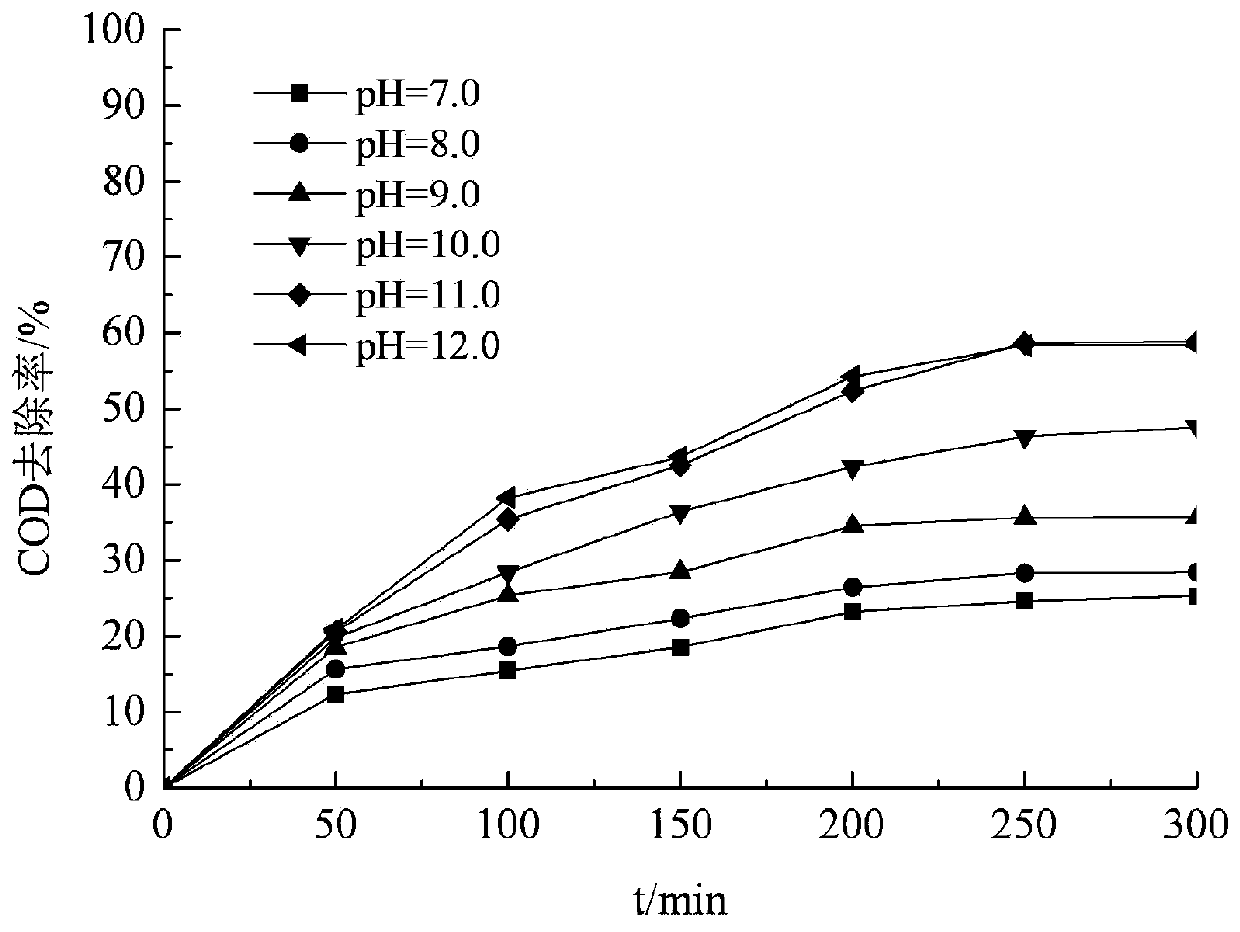

[0042] In order to further optimize the conditions of the refined cotton black liquor, this example examines the best treatment plan from the three aspects of concentration, temperature and pH. In the present embodiment-take potassium persulfate as an example.

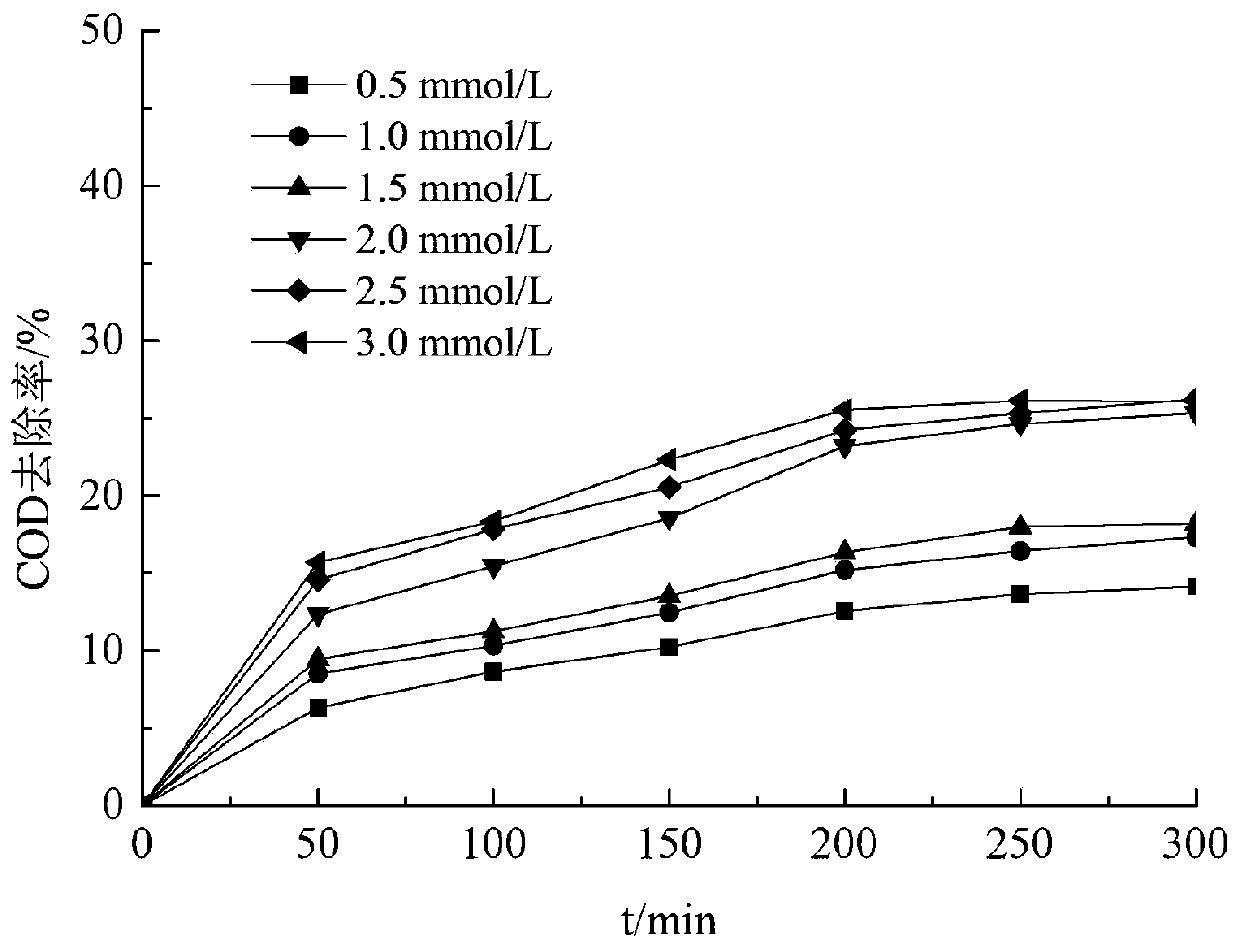

[0043] (1) Effect of potassium persulfate concentration on COD removal effect

[0044] Firstly, at room temperature of 20°C and pH=7.0, adding 50ml of 0.5mmol / L, 1.0mmol / L, 1.5mmol / L, 2.0mmol / L, 2.5mmol / L and 3.0mmol respectively to 1L of refined cotton black liquor / L total of 6 concentration gradient potassium persulfate solutions to analyze the change of COD removal effect in refined cotton black liquor (attached figure 1 ). With the increase of the concentration of potassium persulfate, the removal rate of COD in the refined cotton black liquor also increased obviously sequentially. It can be found that when 3.0mmol / L potassium persulfate is added for 250min, the removal rate of COD in the refined cotton black l...

Embodiment 3

[0054] In this embodiment, in this embodiment, potassium peroxymonosulfate is used as an example to investigate the best treatment plan from three aspects of concentration, temperature and pH.

[0055] (1) Effect of potassium peroxymonosulfate concentration on COD removal effect

[0056] Firstly, at room temperature of 20°C and pH=7.0, adding 50ml of 0.5mmol / L, 1.0mmol / L, 1.5mmol / L, 2.0mmol / L, 2.5mmol / L and 3.0mmol respectively to 1L of refined cotton black liquor / L, a total of 6 concentration gradient potassium peroxymonosulfate solutions, to analyze the change of COD removal effect in the refined cotton black liquor, as shown in the attached Figure 7 As shown, along with the increase of potassium peroxomonosulfate concentration, the removal rate of COD in the refined cotton black liquor also obviously increases successively, can find: when adding 2.5mmol / L potassium peroxymonosulfate 300min, in the refined cotton black liquor The removal rate of COD reached the maximum va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com