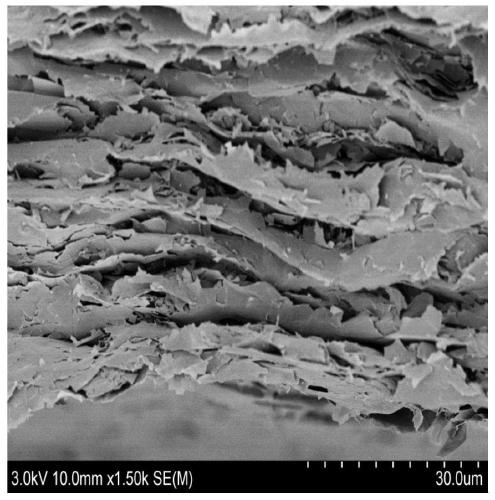

Bionic laminated graphene/perylene diimide derivative heat conduction film and preparation method thereof

A peryleneimide and thermally conductive film technology is applied in the field of biomimetic layered graphene/peryleneimide derivative thermally conductive films and their preparation to achieve the effects of improving longitudinal heat transfer paths and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0021] (1) Add 0.5g perylene anhydride, 5.5g polyethylene polyamine, 40mL xylene in a three-necked flask, reflux under N 2 Under protection, the temperature was raised to 80°C. After reacting for 10 hours, the solution was precipitated in 40mL of methanol, and the filter cake was washed with distilled water several times until the filtrate was neutral, and dried overnight at 60°C in a vacuum oven to obtain perylene imide Amine Derivatives (APBI).

[0022] (2) Take 1.0 g of graphene slurry with a solid content of 0.05 g, add 300 mL of deionized water and ultrasonicate for 30 minutes, then add 0.5 mg of APBI synthesized in step (1), continue ultrasonic dispersion for 1 hour, and filter the dispersion to form a film , after drying at 80° C., using a mechanical pressure of 10 MPa and a pressing time of 5 minutes, a peryleneimide functionalized graphene heat-conducting film (APBI-GNS) with a thickness of 20 μm was obtained. The measured transverse thermal conductivity is 287W / m·K,...

Embodiment approach 2

[0024] (1) Add 1.0g perylene anhydride, 11g polyvinylpolyamine, 40mL xylene in a three-necked flask, reflux under N 2 Under protection, the temperature was raised to 80°C, and after 12 hours of reaction, the solution was precipitated in 40mL of methanol, and the filter cake was washed with distilled water several times until the filtrate was neutral, and dried overnight at 60°C in a vacuum drying oven to obtain perylene imide Amine Derivatives (APBI).

[0025] (2) Take 1.0 g of graphene slurry with a solid content of 0.05 g, add 300 mL of deionized water for ultrasonication for 30 min, then add 1.0 mg of APBI synthesized in step (1), continue ultrasonic dispersion for 1.5 h, and suction filter the dispersion into After the film was dried at 80°C, a mechanical pressure of 10 MPa was used for a pressing time of 5 minutes to obtain a peryleneimide functionalized graphene thermally conductive film (APBI-GNS) with a thickness of 20 μm. The measured transverse thermal conductivity ...

Embodiment approach 3

[0027] (1) Add 1.0g perylene anhydride, 11g polyvinylpolyamine, 40mL xylene in a three-necked flask, reflux under N 2 Under protection, the temperature was raised to 80°C. After reacting for 12 hours, the solution was precipitated in 50mL of methanol, and the filter cake was washed with distilled water several times until the filtrate was neutral, and dried overnight at 60°C in a vacuum drying oven to obtain perylene imide Amine Derivatives (APBI).

[0028] (2) Take 1.0 g of graphene slurry with a solid content of 0.05 g, add 400 mL of deionized water and ultrasonicate for 30 min, then add 1.5 mg of APBI synthesized in step (1), continue ultrasonic dispersion for 2 h, and filter the dispersion to form a film , after drying at 80° C., using a mechanical pressure of 12 MPa and a pressing time of 8 minutes, a peryleneimide functionalized graphene thermally conductive film (APBI-GNS) with a thickness of 24 μm was obtained. The measured transverse thermal conductivity is 210W / m·K,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

| tensile properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com