Sunscreen spray

A technology of sunscreen spray and weight percentage content, which is applied in the direction of cosmetics, cosmetic preparations, dressing preparations, etc., which can solve the problems of poor effect, insufficient purity of materials, deterioration of materials, etc., and achieve good sun protection effect and moisturizing Good effect and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8 and comparative example 1~3

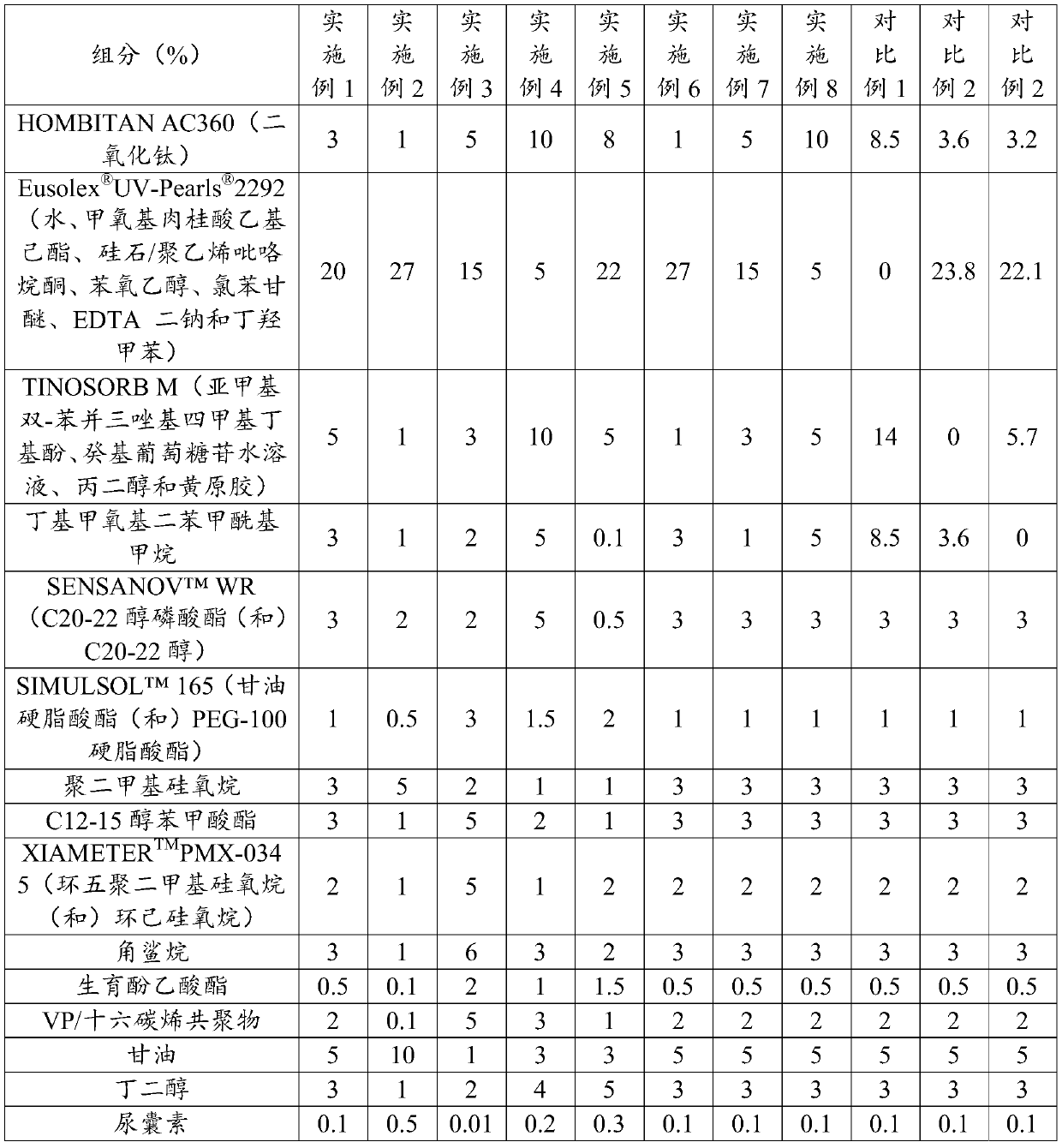

[0040] The formulations of the sunscreen spray described in Examples 1 to 8 and Comparative Examples 1 to 3 are shown in Table 1, and the preparation method of the sunscreen spray described in Examples 1 to 8 and Comparative Examples 1 to 3 comprises the following steps:

[0041] 1. Preparation of slurry: Mix and stir C12-15 alcohol benzoate, titanium dioxide (CI77891) and squalane evenly, and then grind it three times with a three-roller until it is completely dispersed;

[0042] 2. C20-22 alcohol phosphate (and) C20-22 alcohol, glyceryl stearate (and) PEG-100 stearate, polydimethylsiloxane, cyclopentasiloxane (and) Cyclohexasiloxane, tocopheryl acetate, butylmethoxydibenzoylmethane, VP / hexadecene copolymer, methylparaben, and propylparaben are added to the oil phase pot in turn, and heated Stir and heat up to 75-85°C;

[0043] 3. Add the slurry prepared in step 1, continue to stir and heat up to 75-85°C;

[0044] 4. Put deionized water, glycerin, butylene glycol, allantoin, ...

Embodiment 9

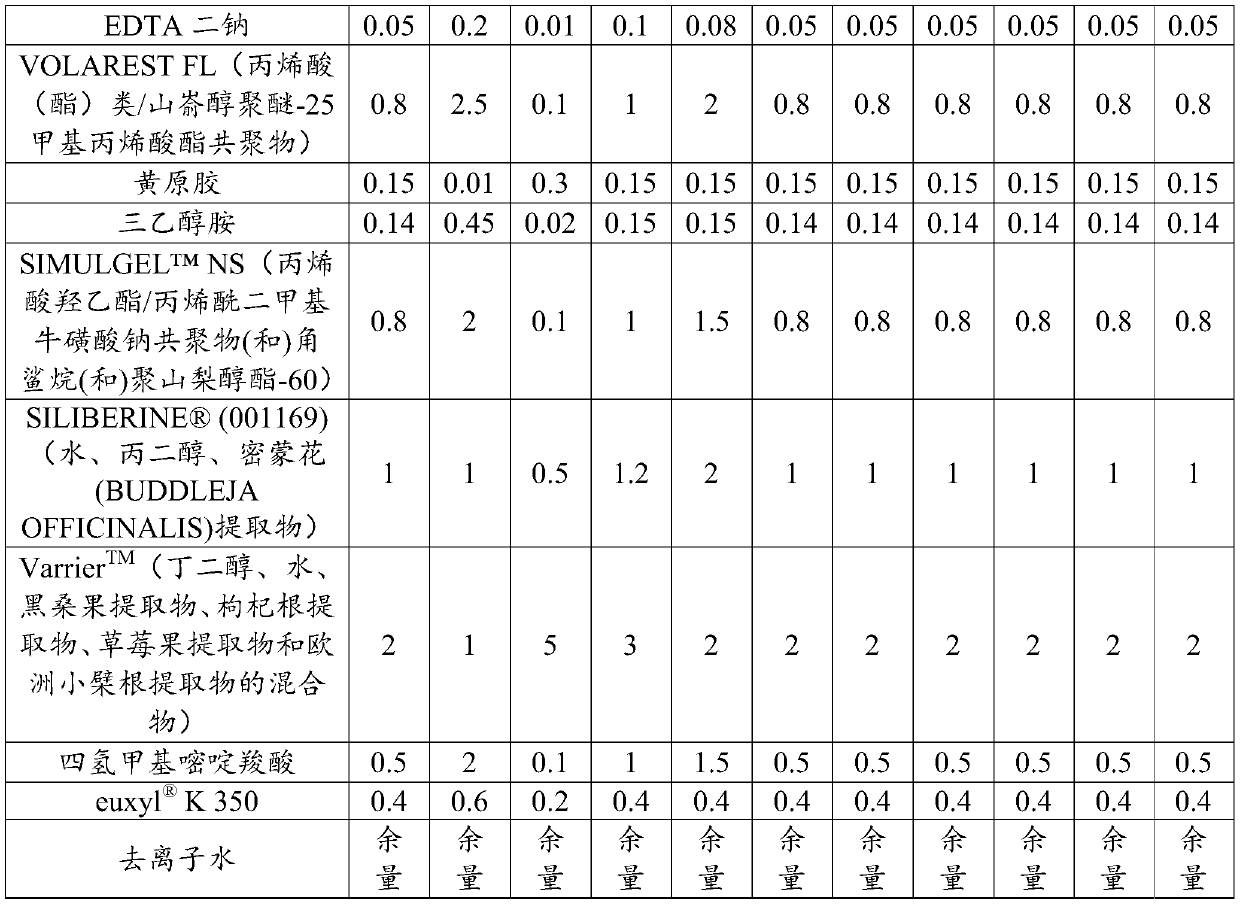

[0054] In order to verify the skin feel and atomization effect of each group of sunscreen sprays, 88 volunteers with oily or mixed skin, aged 18 to 35, were selected and divided into 11 groups, with 8 people in each group, and tried Examples 1 to 8 respectively. 1. For the sunscreen spray described in Comparative Examples 1 to 3, the skin feel and atomization effect are scored as 5 points, 4 points, 3 points, 2 points, 1 point, and 0 points in order from good to bad, and the average value of the statistical test is calculated. The test results are shown in Table 2.

[0055] Table 2 Skin feel and atomization effect test results of Examples 1-8 and Comparative Examples 1-3

[0056]

[0057] The above test data show that the skin feel of Examples 1-8 is better than that of Comparative Examples 1-3, and the skin feel and atomization effect of Example 1 are the best.

Embodiment 10

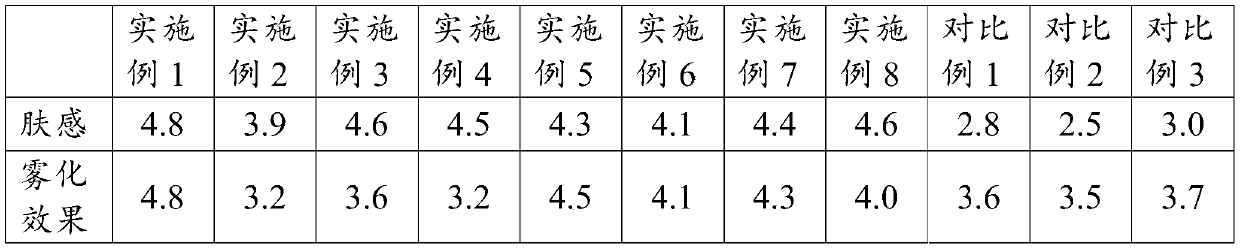

[0059] The sunscreen sprays of Examples 1-8 and Comparative Examples 1-3 are tested for product performance, and the specific testing methods are as follows:

[0060] 1. Accurately weigh 100mg of each sunscreen spray sample into a 50ml bottle, add a mixture of absolute ethanol and absolute ether in a ratio of 1:1 as a solvent to make a solution. Pour the prepared solution into a 1cm×1cm×5cm quartz colorimetric cell, and measure the ultraviolet light transmittance in the wavelength range of 290-400nm in a well-adjusted ultraviolet spectrophotometer.

[0061] 2. For volunteer subjects, first use the skin moisture and oil content test pen to test the water and oil content of the skin when no sunscreen is applied. After using the above sunscreen, use the test pen to test the water and oil content again.

[0062] 3. The specific test results are shown in Table 3.

[0063] Table 3 product performance test results

[0064]

[0065] It can be seen from the test results that Examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com