Method for preparing metal oxide composite material with polymetallic salt solution

A technology for polymetallic salts and composite materials, which is applied in the field of preparing metal oxide composite materials from polymetallic salt solutions, and can solve the problems of solution complexity, high metal concentration, and failure to achieve separation and purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

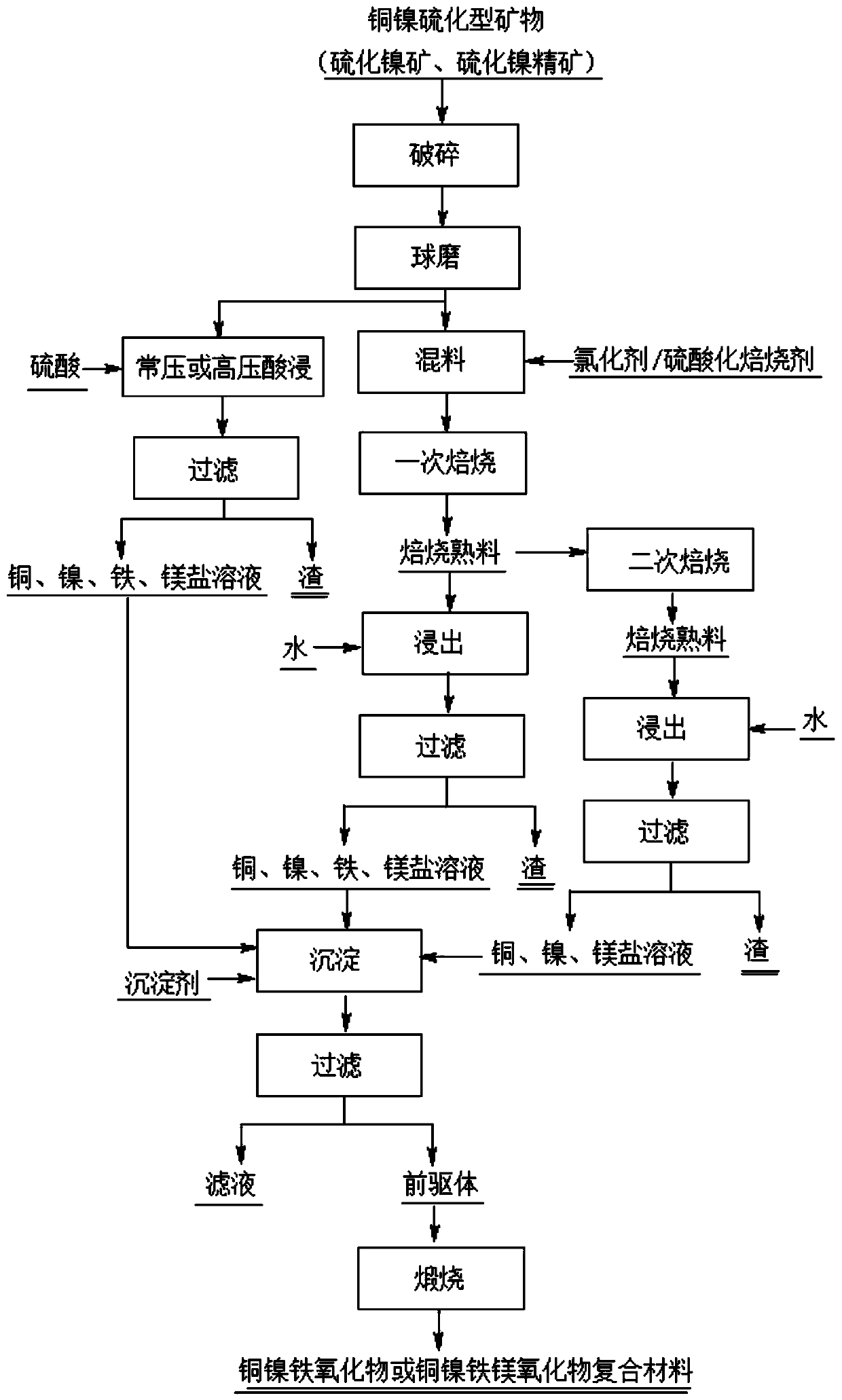

[0052] A method for preparing metal oxide composite materials from a polymetallic salt solution, which is to prepare iron oxide and metal oxide composite materials after removing iron from the polymetallic salt solution prepared by nickel sulfide roasting-water leaching, see figure 1 , including the following steps:

[0053] Step 1: Preparation of Polymetallic Salt Solution

[0054] Xinjiang low-grade nickel sulfide ore is crushed, ball milled, mixed with ammonium sulfate and sodium sulfate (according to mass ratio, ammonium sulfate: sodium sulfate = 1:1), roasted once, water leached and filtered to obtain more Metal sulfate solution, wherein, in polymetallic sulfate solution, nickel ion concentration is: 0.09mol / L, copper ion concentration is: 0.11mol / L, iron ion (comprising Fe 2+ and Fe 3+ , the total iron ion content is usually expressed as Fe 3+ Density meter) concentration: 1.6mol / L, magnesium ion concentration: 0.02mol / L.

[0055] Step 2: Add Precipitant to Prepare M...

Embodiment 2

[0058] A method for preparing a metal oxide composite material from a polymetallic salt solution, which is to prepare iron oxide and metal oxide composite materials from the polymetallic salt solution prepared by leaching and filtering nickel sulfide ore under pressure with sulfuric acid, see figure 1 , including the following steps:

[0059] Step 1: Preparation of Polymetallic Salt Solution

[0060] Jinchuan low-grade nickel sulfide ore is crushed, ball milled, mixed with sulfuric acid, leached under pressure at 1MPa, and filtered to obtain a polymetallic sulfate solution, wherein the concentration of nickel ions in the polymetallic sulfate solution is: 0.16mol / L, copper ion concentration: 0.09mol / L, iron ion concentration: 0.16mol / L, magnesium ion concentration: 0.44mol / L.

[0061] Step 2: Add Precipitant to Prepare Metal Oxide Composite

[0062] Heat the polymetallic sulphate solution to 60°C and under the condition of a stirring rate of 200r / min, add a precipitant ammon...

Embodiment 3

[0064] A method for preparing a metal oxide composite material from a polymetallic salt solution, which is a method for preparing a metal oxide composite material from a polymetallic salt solution prepared by nickel sulfide concentrate through sulphating roasting-water leaching. The process flow chart is shown in figure 1 ,Specific steps are as follows:

[0065] Step 1: Preparation of Polymetallic Salt Solution

[0066]Jinchuan low-grade nickel sulfide concentrate is crushed, ball milled, mixed with ammonium bisulfate and sodium sulfate (according to mass ratio, ammonium bisulfate: sodium sulfate = 1:1), and roasted once to obtain roasted clinker. The roasted clinker is subjected to secondary roasting to remove iron, water leaching, and filtration to obtain a polymetallic sulfate solution, wherein the concentration of nickel ions in the polymetallic sulfate solution is: 0.19mol / L, and the concentration of copper ions is: 0.13mol / L, Iron ion concentration: 0.009mol / L, magnesiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com