HDPE resin with high rheological property and use of HDPE resin in preparation of communication cable insulating material

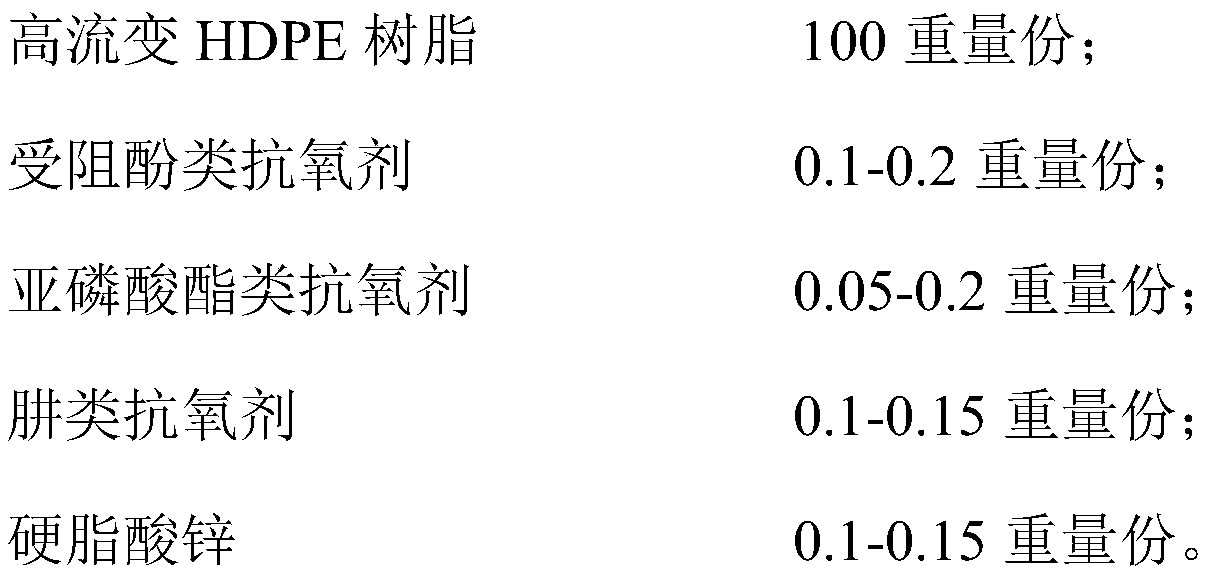

A technology for communication cables and insulation materials, which is applied in the field of preparation of communication cable insulation materials and high-rheology HDPE resins, and can solve problems such as unfavorable communication cable processing, mechanical properties of insulation materials, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0037] Take the silica gel carrier (the pore volume is 2.3-2.5ml / g) in a nitrogen atmosphere, and carry out drying treatment under the condition of 200 ° C; adopt the conventional solution impregnation method to carry out the loading of the silica gel after the above treatment with titanium tetrachloride, and control The loading temperature is 500°C, and the titanium loading amount of the silica gel carrier is adjusted by controlling the addition of titanium tetrachloride to obtain a titanium-modified silica gel carrier; take CrCl 3 Dissolved in ethanol to obtain a chromium salt solution, and mix the titanium-modified support with the chromium salt solution at a volume ratio of 1:5, and pre-dry at 100°C for 24 hours. By controlling the amount of chromium salt added Adjust the chromium loading of the silica gel carrier, dry the prepared powder at 300° C. for 24 hours in a nitrogen atmosphere, and roast the dried powder in a nitrogen atmosphere for 24 hours; Calcination and acti...

preparation example 2

[0043] Take the silica gel carrier (the pore volume is 2.3-2.5ml / g) in a nitrogen atmosphere, and carry out drying treatment under the condition of 150°C; adopt the conventional solution impregnation method to load the silica gel after the above treatment with titanium tetrachloride, and control The load temperature is 450°C, and the titanium loading amount of the silica gel carrier is adjusted by controlling the addition of titanium tetrachloride to obtain a titanium-modified silica gel carrier; take CrCl 3 Dissolved in water to prepare a chromium salt solution, and mix the titanium-modified carrier with the chromium salt solution at a volume ratio of 1:1, pre-dry at 120°C for 12 hours, and control the amount of chromium salt Adjust the chromium loading of the silica gel carrier, dry the prepared powder at 400° C. for 12 hours in a nitrogen atmosphere, and roast the dried powder in a nitrogen atmosphere for 12 hours; Calcination and activation in the air at ℃ to prepare a sup...

preparation example 3

[0048] Take the silica gel carrier (the pore volume is 2.3-2.5ml / g) in a nitrogen atmosphere, and carry out drying treatment under the condition of 300 ° C; use the conventional solution impregnation method to carry out the loading of the silica gel after the above treatment with titanium tetrachloride, and control The load temperature is 600°C, and the titanium loading amount of the silica gel carrier is adjusted by controlling the addition of titanium tetrachloride to obtain a titanium-modified silica gel carrier; take CrCl 3 Dissolved in acetone to obtain a chromium salt solution, and mix the titanium-modified carrier with the chromium salt solution at a volume ratio of 1:8, and pre-dry at 60°C for 36 hours. By controlling the amount of chromium salt added Adjust the chromium loading of the silica gel carrier, dry the prepared powder at 100° C. for 36 hours in a nitrogen atmosphere, and roast the dried powder in a nitrogen atmosphere for 36 hours; Calcination and activation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melt mass flow rate | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com