Aqueous dispersion of high solid content fluorine-containing hydroxy polyacrylate and its preparation method and application

A technology of fluorine-containing hydroxyl polyacrylate and high solid content, applied in polyurea/polyurethane coatings, biocide-containing paints, antifouling/underwater coatings, etc., can solve the problem of reducing the hardness of the coating film and reducing the recoating of the coating film Solvent resistance and other issues, to achieve the effect of excellent solvent resistance, low VOC, good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

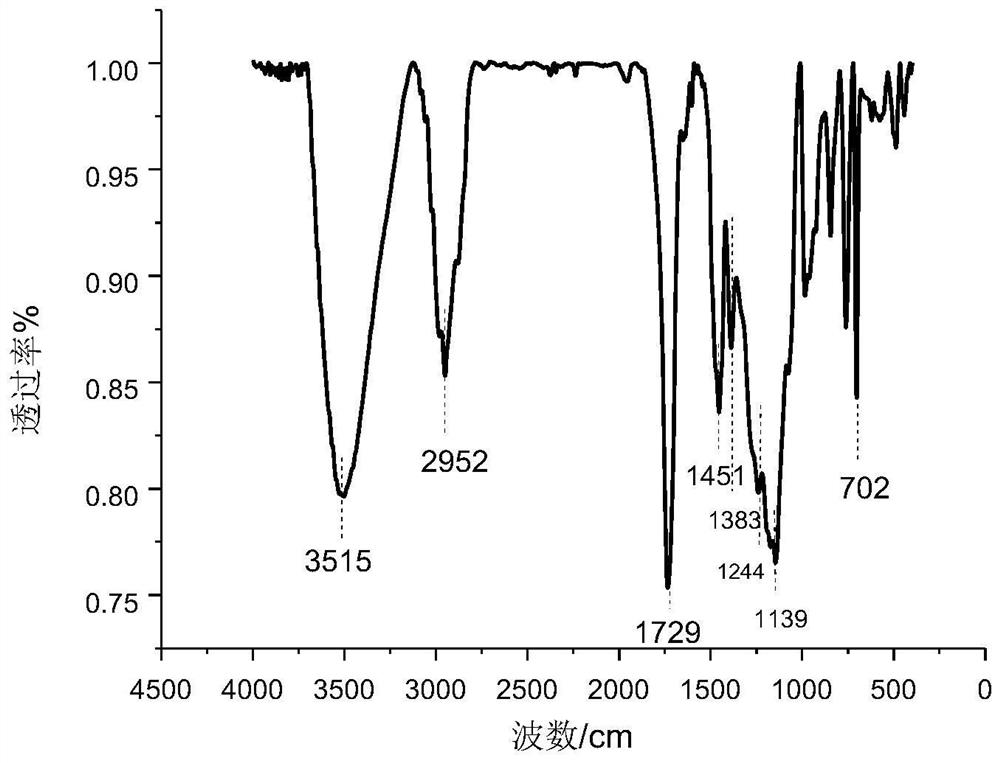

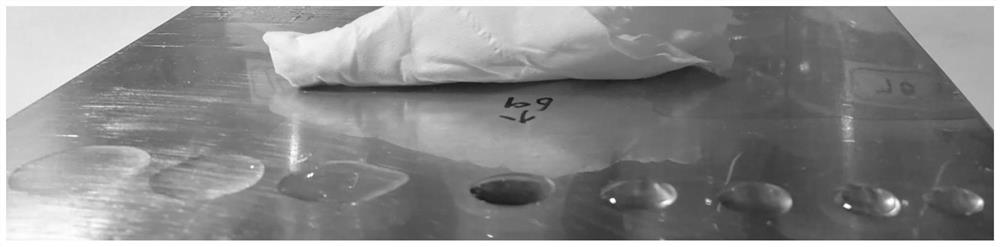

Method used

Image

Examples

Embodiment 1

[0040] 1) Preparation of high solid content fluorine-containing hydroxyl polyacrylate aqueous dispersion

[0041] In parts by mass, the raw material components and consumption are as follows in Table 1

[0042] Table 1

[0043]

[0044] Preparation: Under nitrogen protection, mix vinyl fluoride monomer, vinyl sulfonate monomer, acrylic monomer, initiator and chain transfer agent to prepare a mixed solution, add 10% of the mixed solution to the reactor, Stir and heat up to 70°C for 30 minutes, add the remaining mixture into the reactor within 4 hours, and keep it warm for 2 hours to obtain a fluorine-containing hydroxyl polyacrylate prepolymer; then lower the temperature to below 50°C, add a neutralizing agent for neutralization, and add water High-speed dispersion was carried out at 1000 rpm at 30°C to prepare an aqueous dispersion.

[0045] Performance of high solid content fluorine-containing hydroxyl polyacrylate aqueous dispersion: solid content is 45%, viscosity (25°...

Embodiment 2

[0057] (1) Preparation of high solid content fluorine-containing hydroxyl polyacrylate aqueous dispersion

[0058] In terms of parts by mass, the raw material components and consumption are as shown in Table 3

[0059] table 3

[0060]

[0061]

[0062] Preparation of vinyl fluoride monomer-modified polyacrylate: under nitrogen protection, mix vinyl fluoride monomer, vinyl sulfonate monomer, acrylic monomer, initiator and chain transfer agent to prepare a mixed solution, Add 10% mixed solution into the reactor, stir and raise the temperature to 75° C. for 30 minutes, add the remaining mixture into the reactor within 4 hours, and keep it warm for 1.5 hours to obtain a fluorohydroxypolyacrylate prepolymer. Then lower the temperature to below 50°C, add a neutralizing agent for neutralization, add water at 30°C and perform high-speed dispersion at 1500 rpm to obtain an aqueous dispersion.

[0063]Vinyl fluoride monomer-modified polyacrylate aqueous dispersion properties: s...

Embodiment 3

[0071] (1) Preparation of high solid content fluorine-containing hydroxyl polyacrylate aqueous dispersion

[0072] In parts by mass, the raw material components and consumption are as shown in Table 5

[0073] table 5

[0074]

[0075] Preparation of vinyl fluoride monomer modified polyacrylate: under nitrogen protection, vinyl fluoride monomer, vinyl silicon monomer, vinyl sulfonate monomer, acrylic monomer, initiator and chain transfer agent Mix to prepare a mixed solution, add 15% of the mixed solution to the reactor, stir and heat up to 75°C for 35 minutes, add the remaining mixture to the reactor within 5 hours, and keep it warm for 1.5 hours to obtain vinyl fluoride monomer-modified Polyacrylate prepolymer. Then lower the temperature to below 50°C, add a neutralizing agent for neutralization, add water at 30°C and perform high-speed dispersion at 2500 rpm to obtain an aqueous dispersion.

[0076] Vinyl fluoride monomer-modified polyacrylate aqueous dispersion prope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com