A kind of toughened conductive epoxy resin composite material and preparation method thereof

A technology of conductive epoxy resin and composite materials, which is applied in the field of epoxy resin composite materials, can solve the problems of high cost, complex and cumbersome process steps, etc., and achieve the effect of toughening and strengthening, improving impact resistance and reducing defect degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

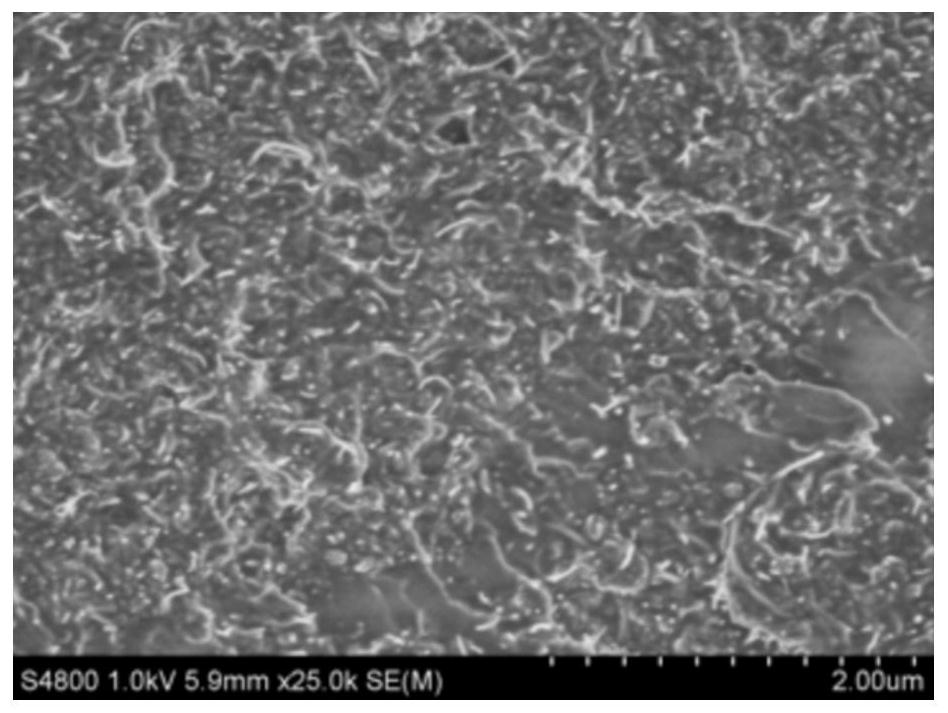

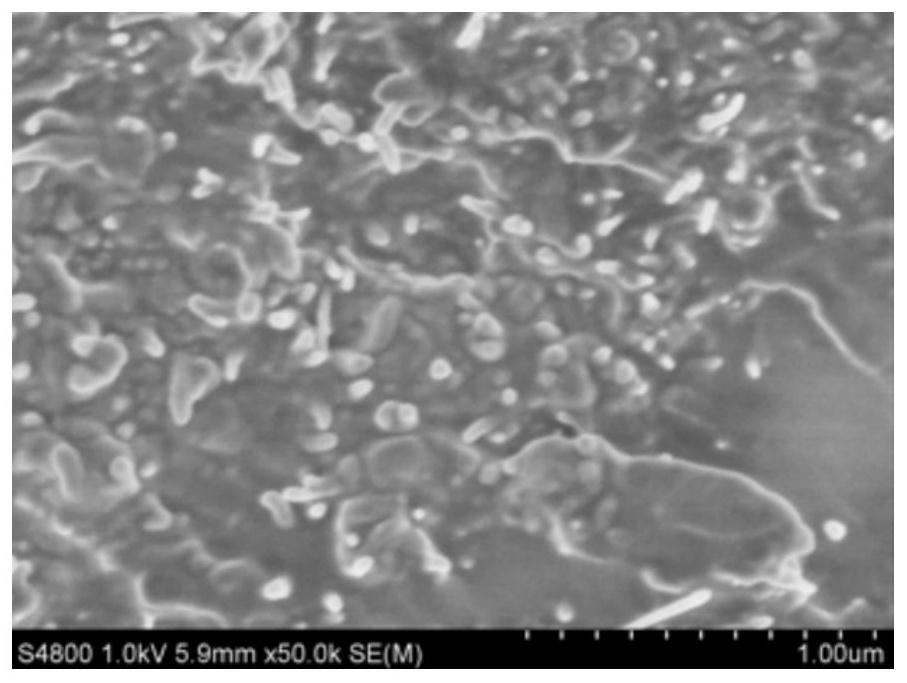

Image

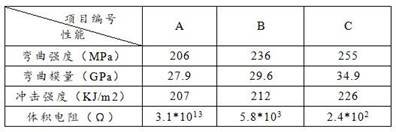

Examples

Embodiment 1

[0041] Example 1 A new toughened conductive epoxy resin composite material and preparation method.

[0042] Raw material ratio composition: 200g methylol bisphenol A epoxy resin, 12g graphene, 3.5g hydroxylated carbon nanotubes, 3.5g conductive carbon black, 1.5g polyvinylpyrrolidone, 8g curing agent, 0.4g g defoamer.

[0043] (1) Weigh 200g of hydroxymethyl bisphenol A epoxy resin, heat it to 80°C, reduce the viscosity to 2300-2500mPa·s, add 1.5g of polyvinylpyrrolidone, stir evenly;

[0044] (2) Add 12g of graphene, 3.5g of hydroxylated carbon nanotubes and 3.5g of conductive carbon black to the methylol bisphenol A epoxy resin, and then keep stirring at 2200rpm for 70min to obtain a pre-dispersed material;

[0045] (3) Transfer the pre-dispersed material to a 500ml nano-sand mill, use zirconium balls with a diameter of 1mm and 2mm with a mass ratio of 1:1, and perform a shear grinding cycle for 6 hours;

[0046] (4) The material treated in step (3) is at 120°C under negat...

Embodiment 2

[0050] Example 2 A novel toughened conductive epoxy resin composite material and preparation method.

[0051] Raw material ratio composition: 1500g of bisphenol F epoxy resin, 12g of graphene, 16g of carboxylated carbon nanotubes, 40g of conductive carbon black, 18g of sodium dodecyl sulfonate, 50g of curing agent, 4.5g of disinfectant Foaming agent.

[0052] (1) 1500g of bisphenol F epoxy resin, add 600g of toluene, stir evenly, the viscosity drops to 1000-1600mPa·s, add 18g of sodium dodecyl sulfonate, stir evenly;

[0053] (2) Add 70g of graphene, 16g of carboxylated carbon nanotubes and 40g of conductive carbon black to bisphenol F epoxy resin, and then keep stirring at 1500rpm for 90min to obtain pre-dispersed material;

[0054] (3) The pre-dispersed material is transferred to a 3L nano-sand mill, equipped with zirconium balls with a diameter of 0.8mm and 1.5mm with a mass ratio of 1.2:1, and the shear grinding cycle is processed for 12h;

[0055] (4) The material treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com