Biomass pyrolysis gasification system coupled pulverized coal fired boiler power plant generation method

A technology for pyrolysis gasification and pulverized coal boilers, which is applied in the gasification process, joint combustion mitigation, and the manufacture of combustible gas, etc. It can solve the problem of high operation and maintenance costs such as labor and maintenance, increase investment costs, and long construction cycle time. problems, to achieve the effect of small biomass power generation project, low operation and maintenance cost ratio, and saving investment quota

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

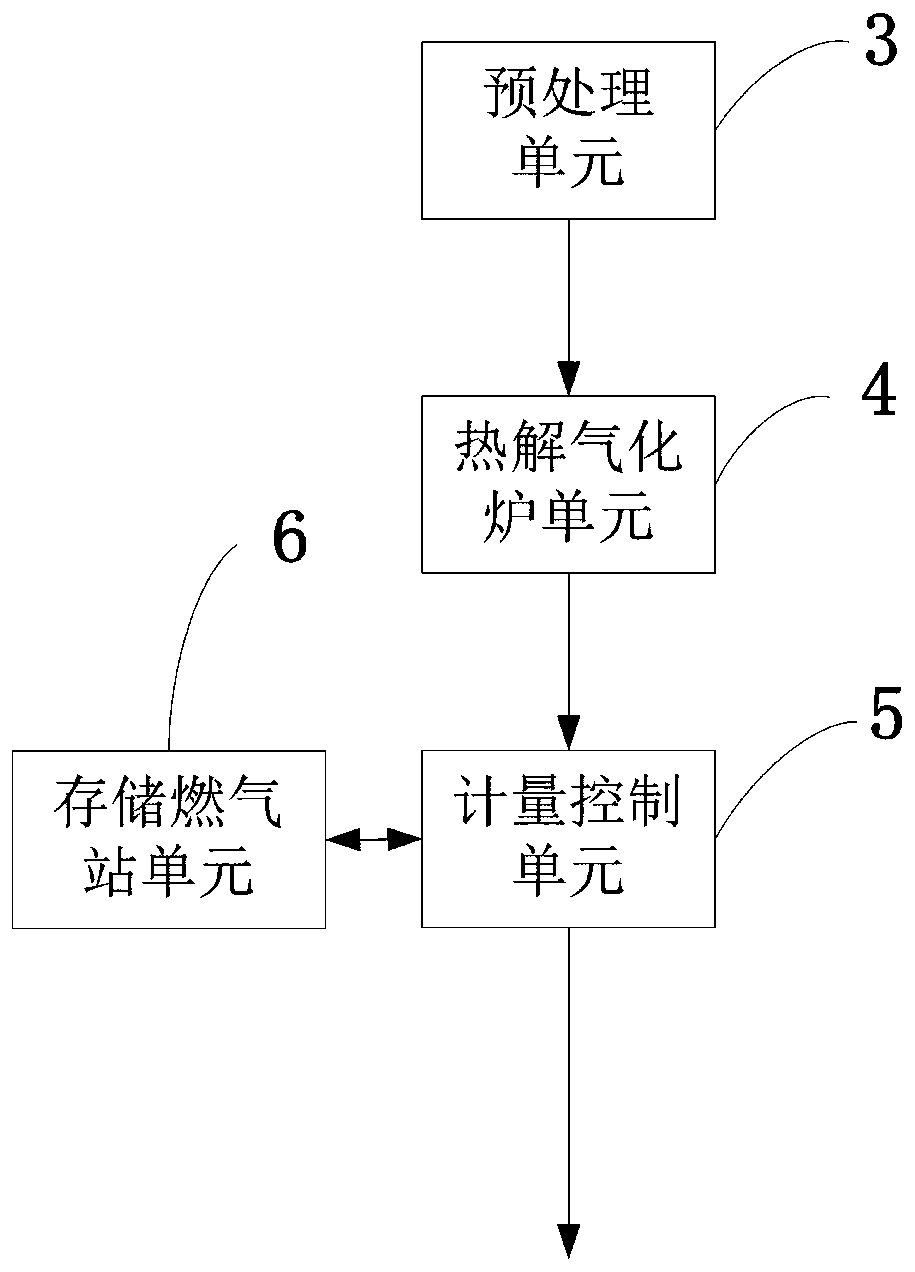

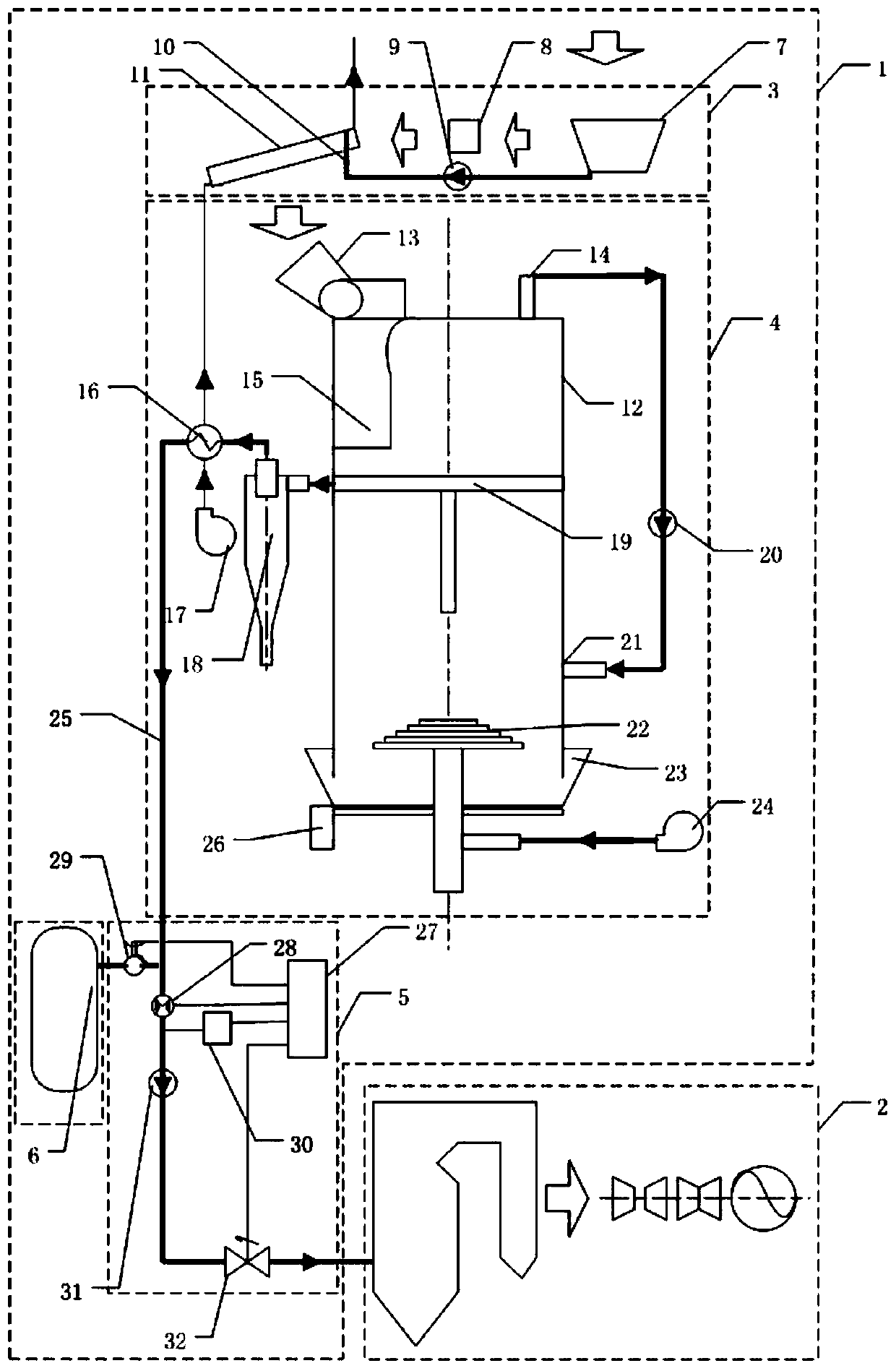

[0056] The general biomass pyrolysis gasification system coupled pulverized coal boiler power plant power generation process provided by the embodiment of the present invention is suitable for agricultural and forestry waste residues such as straw; specifically includes: when using agricultural and forestry waste residues such as straw as biomass fuel, agricultural and forestry waste After being pulverized and dried in the pretreatment unit, the residue enters the pyrolysis gasifier for pyrolysis and gasification to produce combustible gas, which is measured and controlled by the metering control unit, and the storage gas station stores and increases the supply of combustible gas for power plant combustion as needed generate electricity.

Embodiment 2

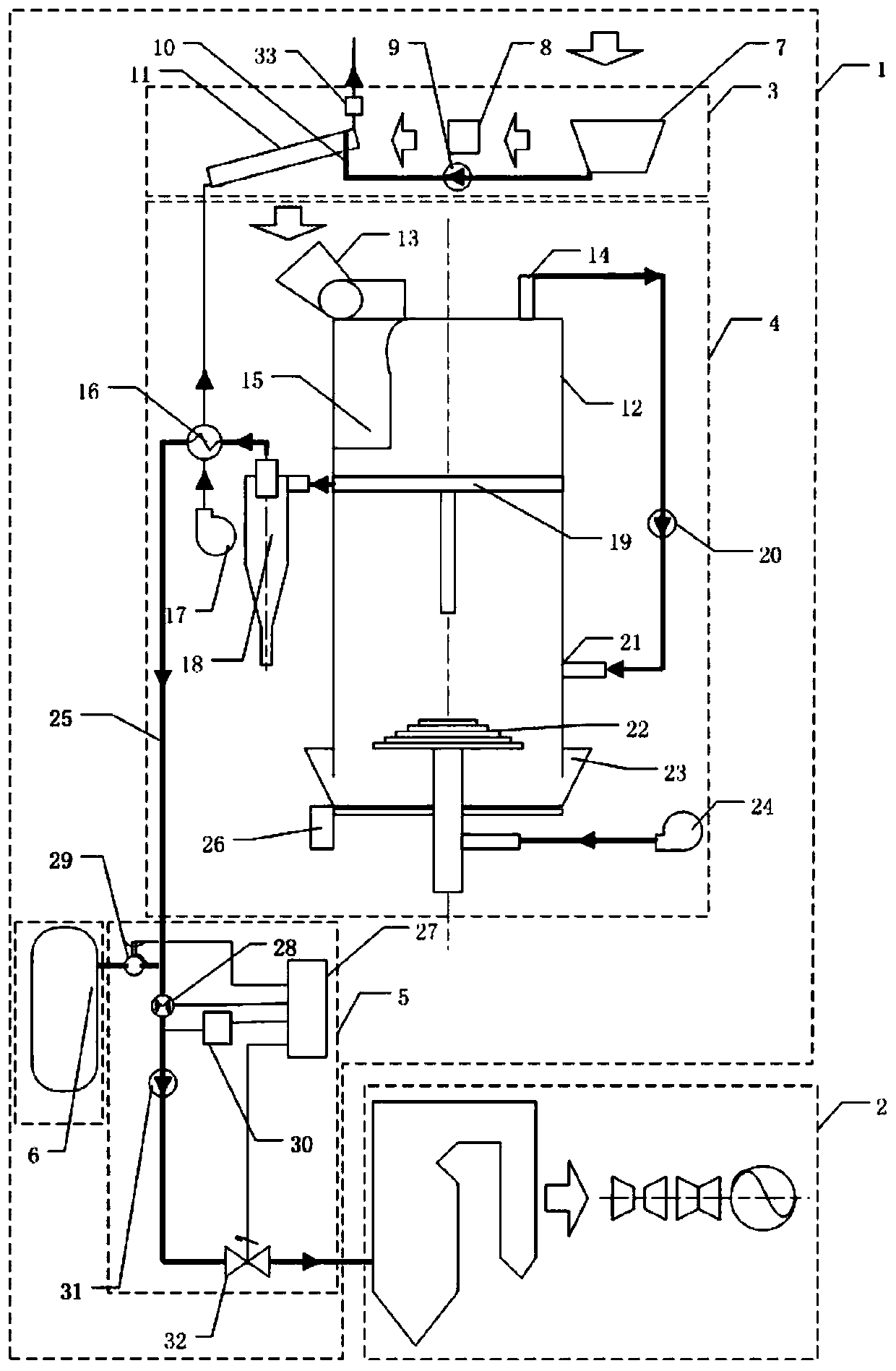

[0058] The embodiment of the present invention provides a biomass pyrolysis gasification system coupled with a pulverized coal boiler power plant power generation process suitable for sludge in sewage treatment and water bodies, which specifically includes: when using sludge in sewage treatment and water bodies as biomass fuel, the sludge is The pretreatment unit is pulverized and dried. Since the sludge drying exhaust has peculiar smell, it is necessary to install an odor generator 33 to remove the peculiar smell before the drying exhaust can be emptied.

[0059] At the same time, sludge pyrolysis and gasification will produce a small amount of dioxin, which will be eliminated naturally during the combustion and power generation process of the power plant boiler.

[0060] In the combustion power generation process of the coupling pulverized coal boiler power station of the present invention, the mechanism of eliminating dioxin is as follows:

[0061] (1) Combustion and decomp...

Embodiment 3

[0068] The embodiment of the present invention provides a biomass pyrolysis gasification system coupled with a pulverized coal boiler power plant power generation process suitable for domestic waste, which specifically includes: when using domestic waste as biomass fuel, because the waste usually contains a certain amount of scrap iron and steel, and The peculiar smell is serious, and the iron remover 34 is added to remove iron before the pretreatment unit is crushed, and the deodorizer 33 is installed before the drying and exhausting to remove the peculiar smell before being emptied. At the same time, the pyrolysis and gasification of sludge will produce dioxins, which will be eliminated naturally during the combustion and power generation process of power plant boilers.

[0069] At the same time, the pyrolysis and gasification of domestic waste will produce a certain amount of dioxin, which will be eliminated naturally during the combustion and power generation process of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com