A post-plating cooling system and method for hot-dip galvanized steel strip with external electrostatic field

A cooling system and hot-dip galvanizing technology, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of difficult to reach liquid droplets, poor heat dissipation effect, poor product quality, etc., and achieve temperature gradient The effect of small size, fast cooling rate and improved coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

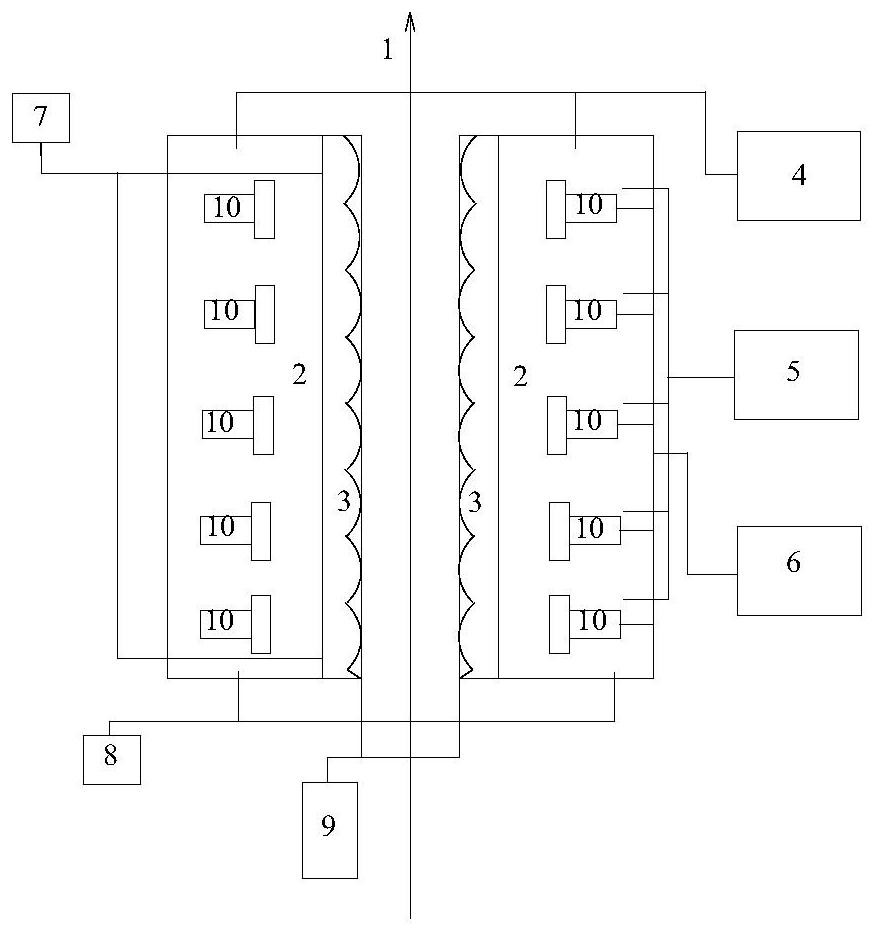

[0038] A specific embodiment of the present invention discloses a post-plating cooling system for hot-dip galvanized strip steel with an applied electrostatic field, such as figure 1 As shown, it includes a spraying device 2, a high voltage device 9, a liquid supply device 6, an air supply device 5, a mist discharge device 4, a drainage device 8, an air cleaning device 7 and connecting pipes.

[0039] The liquid supply device 6 is used to provide water or ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) solution, the equipment of the two solutions is completely distinguished. The above-mentioned liquid supply device 6 includes a liquid storage tank, a liquid level gauge, a filter, an agitator, a heater, an automatic control valve and a circulating pump. The liquid storage tank is used to store water or ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) solution, the liquid level gauge is used to measure the liquid level, the filter is used to filter out impurities in the water...

Embodiment 2

[0050] Another embodiment of the present invention discloses a method for cooling hot-dip galvanized steel strip after plating with an external electrostatic field, comprising the following steps:

[0051] Step 1: Check whether each device of the post-plating cooling system with an external electrostatic field can work normally, check whether the gas volume in the gas supply device is sufficient, and add enough water or ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) solution.

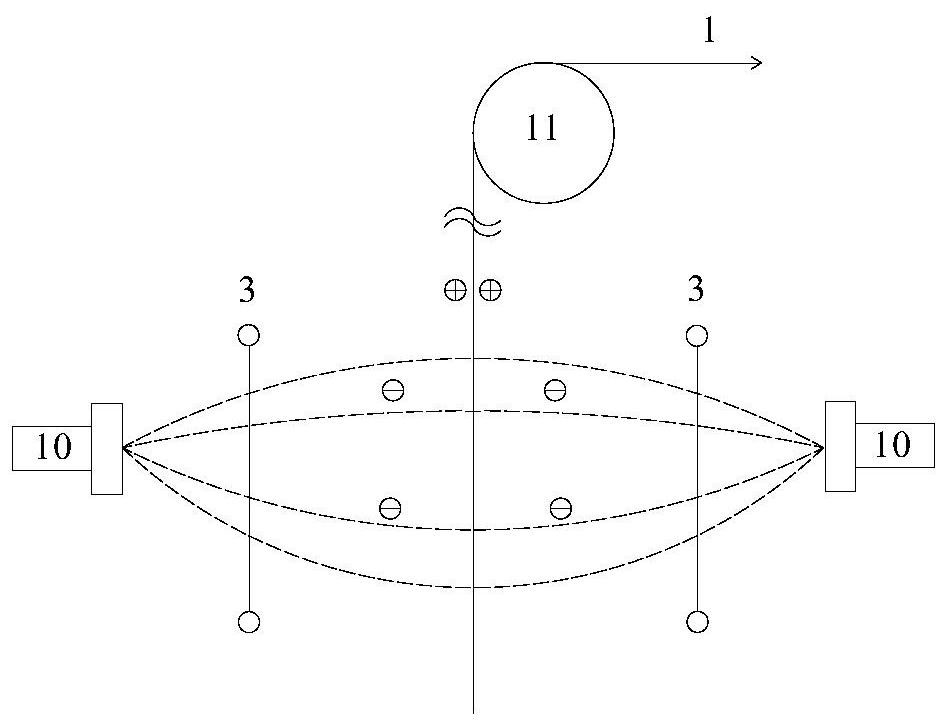

[0052] Step 2: Start the high-voltage device, apply negative voltage to the tungsten wire, ground the roller contacting the strip steel, and form a high-voltage electrostatic zone between the strip steel and the tungsten wire.

[0053] Step 3: Start the air supply device, liquid supply device, spray device, vapor and mist discharge device, drainage device and air purification device in sequence, and use air to convert water or ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) solution is pressurized a...

Embodiment 3

[0055] In this embodiment, the hot-dip galvanized steel strip post-plating cooling system with the addition of an electrostatic field is installed above the air knife and in the zinc layer solidification and crystallization area below the upward vertical air-cooling section, and is used in combination with the air-cooling cooling device.

[0056] The strip steel 1 goes up from the zinc pot through the air knife to adjust the thickness of the coating, and then passes through the post-plating cooling system of the hot-dip galvanized strip steel with an external electrostatic field. The post-plating cooling system is composed of a spraying device 2, a steam mist discharge device 4, an air supply device 5, a liquid supply device 6, an air purification device 7, a drainage device 8, a high voltage device 9 and connecting pipes.

[0057] The air supply device 5 and the liquid supply device 6 provide the spray device 2 with the compressed air and liquid working medium required by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com