A method for etching a silicon wafer, a method for preparing an anti-reflection texture on the surface of a silicon wafer, and a method for etching specific patterns on the surface of a silicon wafer

A silicon wafer surface, anti-reflection technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve the problems of high process cost, metal pollution on the surface of silicon wafer, cumbersome process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

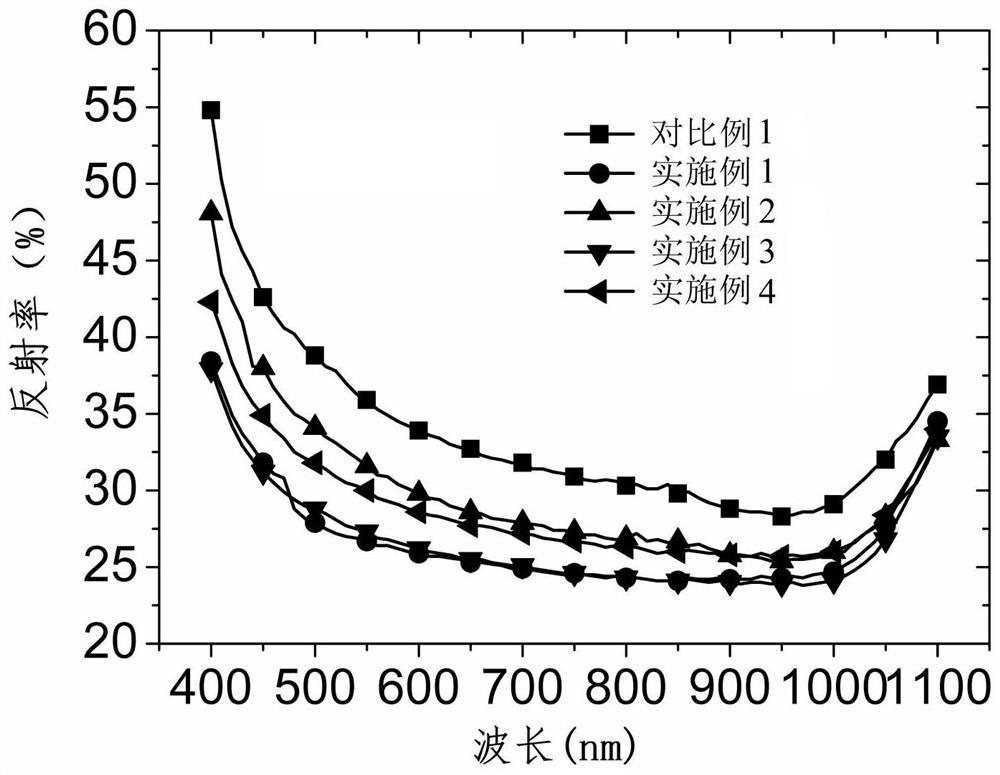

Embodiment 1

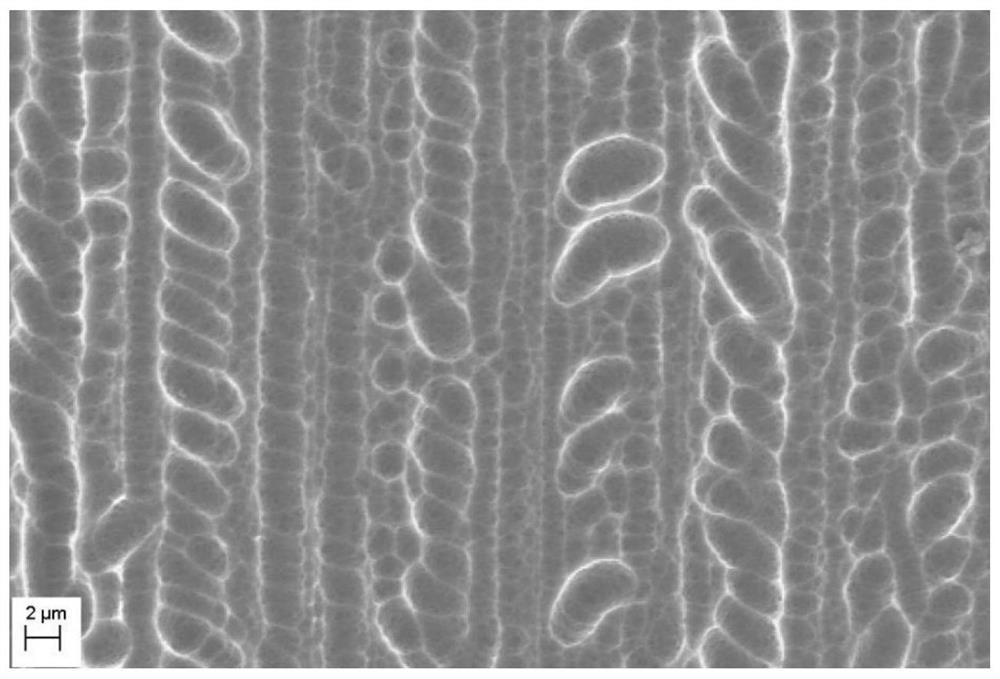

[0049] (1) MnO with a particle size of less than 10 μm 2 The powder particles are mixed with the mixed acid solution of HF and HCl to obtain a suspension; the concentration of HCl is 15.4mol / L, the concentration of HF is 14.3mol / L, MnO 2 The concentration is 8.3g / L;

[0050] (2) At room temperature, place diamond wire-cut polysilicon slices horizontally into the bottom of the suspension to make the MnO 2 The particles naturally settled on the silicon wafer, and were removed after etching for 30 minutes;

[0051] (3) Dip the etched silicon wafer into an alkaline washing solution, and perform an alkaline washing at room temperature for 15 s, and the alkaline washing solution is an aqueous NaOH solution with a concentration of 5.0 wt.%.

[0052] (4) At room temperature, immerse the silicon chip after the alkali cleaning in the pickling solution, pickle for 2min, and the pickling solution is a mixed aqueous solution of HF and HCl, wherein the concentration of HF is 2.8mol / L, and...

Embodiment 2

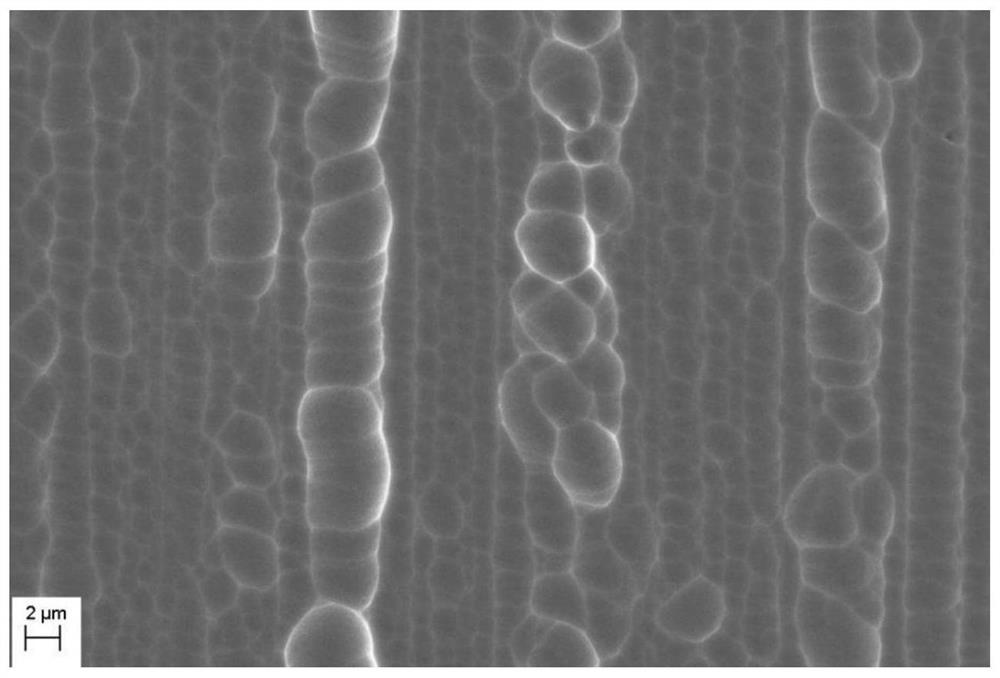

[0055] (1) MnO with a particle size of less than 10 μm 2 The powder particles are mixed with the mixed acid solution of HF and HCl to obtain a suspension; the concentration of HCl is 15.4mol / L, the concentration of HF is 14.3mol / L, MnO 2 The concentration is 16.7g / L;

[0056] (2) Carry out standard RCA cleaning to the polysilicon wafer cut by diamond wire;

[0057] (3) At room temperature, place the diamond wire-cut polysilicon slices cleaned in step (2) horizontally into the bottom of the suspension, so that the MnO 2 The particles naturally settled on the silicon wafer, and were removed after etching for 8 minutes;

[0058] (4) Dip the etched silicon wafer into an alkaline washing solution, and perform an alkaline washing at room temperature for 15 s, and the alkaline washing solution is an aqueous NaOH solution with a concentration of 5.0 wt.%.

[0059] (5) At room temperature, immerse the silicon chip after the alkali cleaning in the pickling solution, pickle for 2min, ...

Embodiment 3

[0062] (1) MnO with a particle size of less than 10 μm 2 The powder particles are mixed with the mixed acid solution of HF and HCl to obtain a suspension; the concentration of HCl is 19.8mol / L, the concentration of HF is 22.6mol / L, MnO 2 The concentration is 33.3g / L;

[0063] (2) Carry out the APM (SC-1) and HPM (SC-2) cleaning in the standard RCA cleaning of the polysilicon wafer cut by diamond wire in sequence;

[0064] (3) At room temperature, place the diamond wire-cut polysilicon slices cleaned in step (2) horizontally into the bottom of the suspension, so that the MnO 2 The particles naturally settled on the silicon wafer, and were removed after etching for 10 minutes;

[0065] (4) Dip the etched silicon wafer into an alkaline washing solution, and perform an alkaline washing at room temperature for 15 s, and the alkaline washing solution is an aqueous NaOH solution with a concentration of 5.0 wt.%.

[0066] (5) At room temperature, immerse the silicon chip after the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com