Self-wound shielding sleeve and fabrication method thereof

A sleeve, self-winding technology, applied in the direction of magnetic field/electric field shielding, power cable with shielding layer/conductive layer, power cable, etc. and other problems, to achieve excellent light aging resistance, good mildew resistance and waterproof performance, and the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

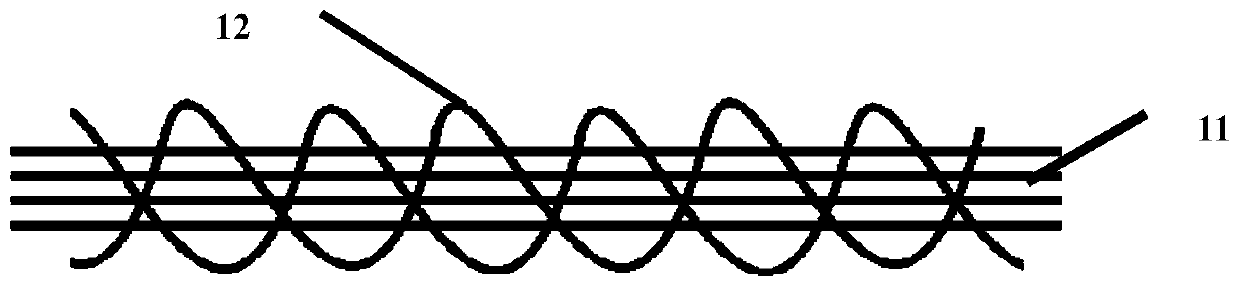

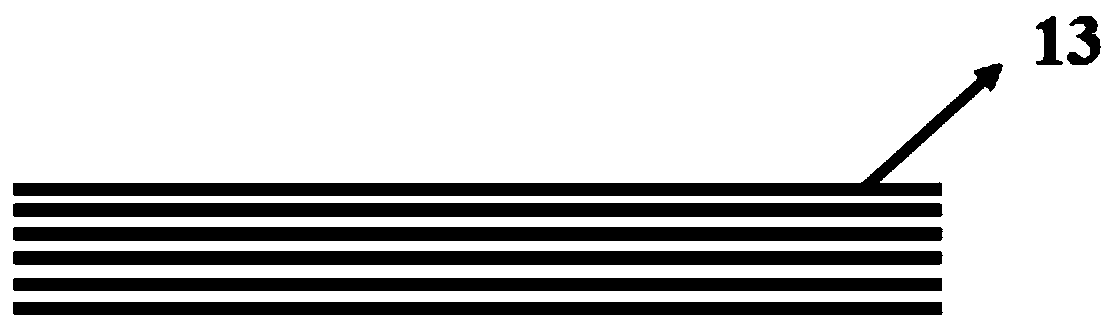

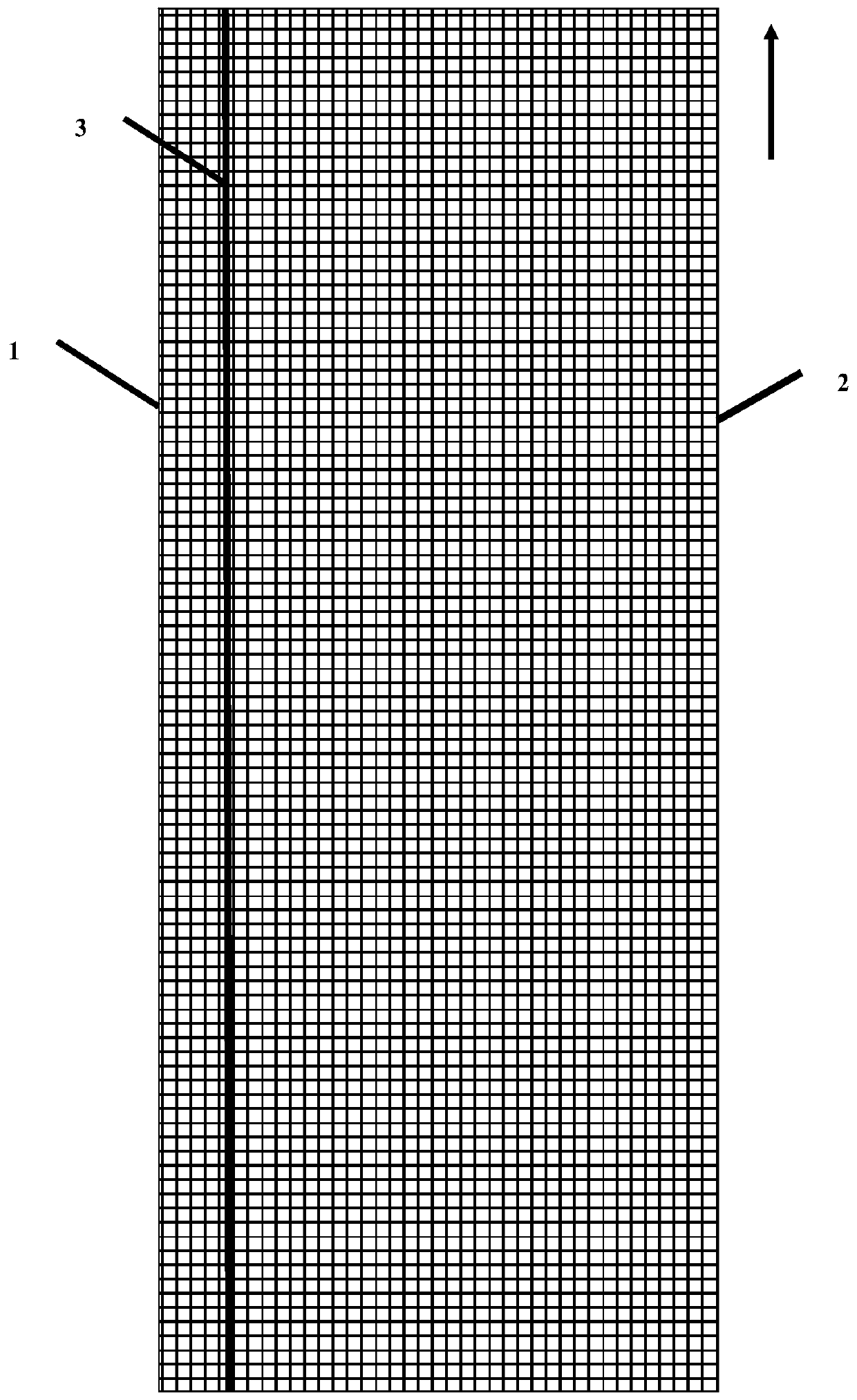

[0045] The warp yarn is composed of 2 strands of polyimide long fiber and tinned copper wire core-spun yarn with constant tension. The multifilament linear density of polyimide long fiber is 300D, the diameter of tinned copper wire is 0.1mm, and the number of wires is 1 root.

[0046] The weft yarn is a polyether ether ketone long fiber monofilament with a monofilament diameter of 0.25mm, and the other is a core-spun yarn of polyimide long fiber and tinned copper wire. The multifilament linear density of polyimide long fiber It is 300D, the diameter of tinned copper wire is 0.1mm, and the number is 1. The warp yarn has a weaving density of 30 strands / inch, and the weft yarn has a weaving density of 20 strands / inch, which is woven into a plain weave tape structure in warp and weft, while one free edge along the warp direction is woven with 2 strands of white aramid long fibers for maximum use. Diameter marking line, the shortest distance between the marking line and the free e...

Embodiment 2

[0051] The warp yarn is composed of 2 strands of aramid long fiber and core-spun yarn of tinned copper foil wire at constant tension. The number is 2.

[0052] The weft yarn is a polyphenylene sulfide long fiber monofilament with a monofilament diameter of 0.5mm, and the other is a core-spun yarn of aramid long fiber and tinned copper foil. The multifilament linear density of aramid long fiber is 500D. The tinned copper foil wire has a width of 0.3 mm, a thickness of 0.08 mm, and two wires. The warp yarn has a weaving density of 30 strands / inch, and the weft yarn has a weaving density of 20 strands / inch. It is woven into a warp and weft twill weave tape structure, and one free edge along the warp direction is woven with 2 strands of white aramid long fibers for maximum use. Diameter marking line, the shortest distance between the marking line and the free edge of the warp is 8mm.

[0053] Pass the woven strip fabric at a speed of 5m / min successively through a treatment tank ...

Embodiment 3

[0057] The warp yarn is composed of 4 strands of polybenzoxazole long fiber and aluminum-magnesium wire core-spun yarn at constant tension. The multifilament linear density of polybenzoxazole long fiber is 1000D, the diameter of aluminum-magnesium wire is 0.3mm, and the number of strands is 2 root.

[0058] The weft yarn is a thermoplastic polyimide long fiber monofilament with a monofilament diameter of 0.35mm, and the other is a core-spun yarn of polybenzoxazole long fiber and aluminum magnesium wire, and a composite of polybenzoxazole long fiber The wire density is 1000D, the diameter of aluminum-magnesium wire is 0.3mm, and the number of wires is 2. The warp yarn has a weaving density of 30 strands / inch, and the weft yarn has a weaving density of 20 strands / inch, which is woven into a plain weave tape structure in warp and weft, while one free edge along the warp direction is woven with 2 strands of white aramid long fibers for maximum use. Diameter marking line, the shor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com