A kind of recoatable antireflective superhydrophobic coating and its preparation method and application

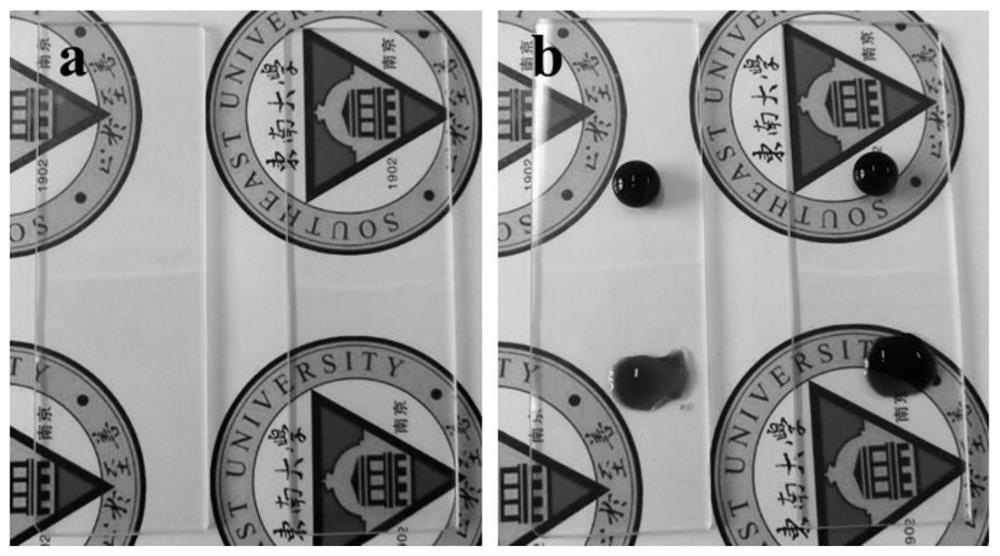

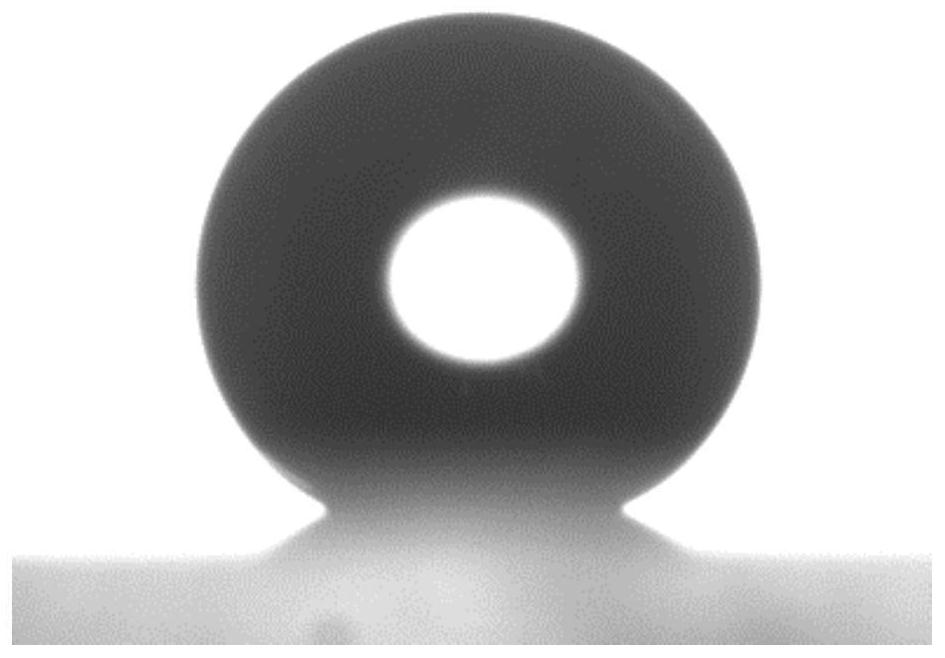

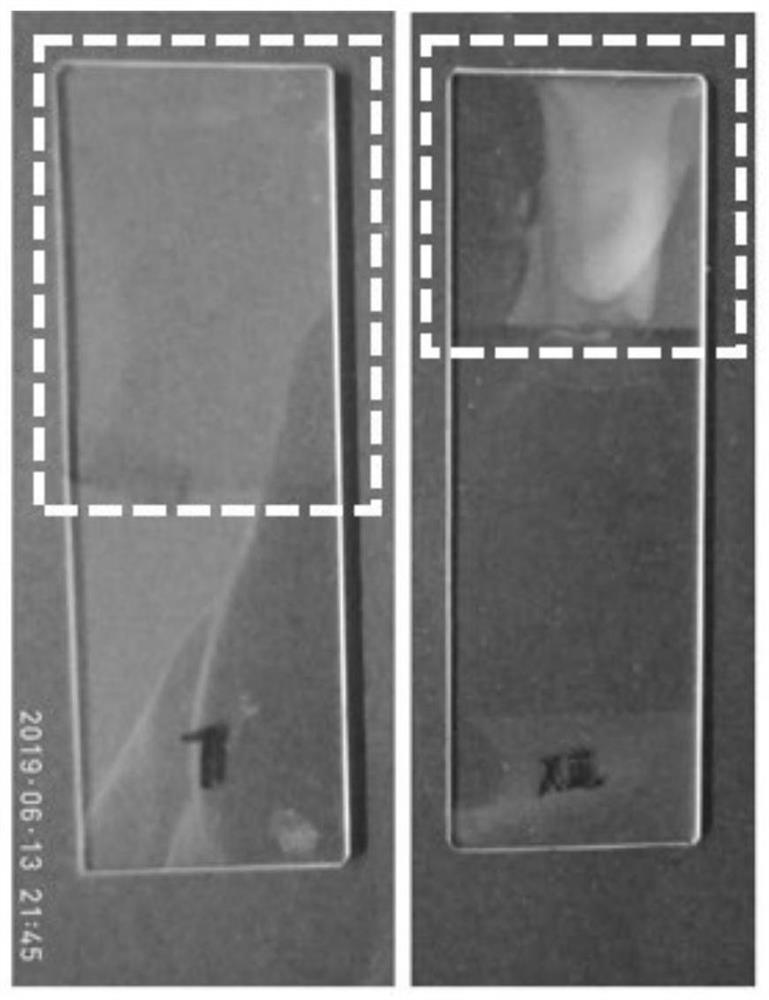

A super-hydrophobic coating and recoating technology, applied in the coating and other directions, can solve the problems that the surface cannot adhere to the super-hydrophobic coating, the coating cannot be applied to the surface, and the film-forming property of the super-hydrophobic coating is poor, and the anti-reflection effect is remarkable. , strong activity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]The preparation method of the chain-type nano-silica sol in this example is as follows: (1) Synthesis of nano-chain seeds, adding 0.5 parts by mass of L-arginine to 40 parts by mass of deionized water and 3 parts by mass of tetraethyl orthosilicate ester mixture, and then reflux and stir the mixture overnight at a speed of <100 rpm and a temperature of 60°C in a reactor equipped with a reflux device to obtain a nanochain seed solution; (2) for nanochain growth, 0.3 mass Parts of L-arginine were added to the mixture of 6 parts by mass of the above-mentioned nanochain seed solution, 6 parts by mass of deionized water and 70 parts by mass of ethanol, and then stood at a constant temperature of 60°C for 12 h to obtain the nanochain solution; (3) Nanochain To set the shape, 1 mass part of tetraethyl orthosilicate was added to the above-mentioned nano-chain solution, and then stirred at 60° C. for 10 h at 600 rpm to obtain the chain-type nano-silica sol. The surfactant is weak...

Embodiment 2

[0044] A kind of preparation method of recoatable antireflection superhydrophobic coating comprises the following steps: step 1. add 30 mole parts ethanol in reaction container, then add 0.1 mole part chain nano-silica sol, stir 5 min at room temperature , with a rotating speed of 100 r / min, to obtain solution A, wherein the preparation method of chain nano-silica sol is as follows: (1) Synthesis of nano-chain seeds, adding 0.05 parts by mass of L-arginine to 40 parts by mass of deionized In a mixture of water and 3 parts by mass of tetraethyl orthosilicate, then the mixture is refluxed and stirred overnight at a speed of <100 rpm and a temperature of 60° C. in a reactor equipped with a reflux device, to obtain a nanochain seed solution; (2) For nanochain growth, add 0.2 parts by mass of L-arginine to the mixture of 6 parts by mass of the above-mentioned nanochain seed solution, 6 parts by mass of deionized water and 60 parts by mass of ethanol, and then let it stand at a const...

Embodiment 3

[0051] A kind of preparation method of recoatable super-hydrophobic coating of anti-reflection, comprises the following steps: step 1. add 60 mole parts ethanol in reaction vessel, then add 3 mole parts chain nano-silica sol, stir 30 min at room temperature , with a rotating speed of 600 r / min, to obtain solution A, wherein the preparation method of chain-type nano-silica sol is as follows: (1) Synthesis of nano-chain seeds, adding 1 mass part of L-arginine to 50 mass parts of deionized In a mixture of water and 5 parts by mass of tetraethyl orthosilicate, then the mixture is refluxed and stirred overnight at a speed of <100 rpm and a temperature of 60° C. in a reactor equipped with a reflux device, to obtain a nanochain seed solution; (2) For nanochain growth, add 0.5 parts by mass of L-arginine to a mixture of 8 parts by mass of the above-mentioned nanochain seed solution, 8 parts by mass of deionized water and 70 parts by mass of ethanol, and then stand at a constant tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com